EOA-UR3510-EGL90-AUB

ID 1403607

Alternative products:

- Course par mors : 42.5 mm

- Force de préhension min.: 50 N

- Force de préhension max.: 600 N

- Alimentation électrique: 24 V DC

- Température ambiant maxi.: 55 °C

Technical details

| Compatible robotique | UR 3/5/10/16 |

|---|---|

| Course par mors [mm] | 42.5 |

| Force de préhension min. [N] | 50.0 |

| Force de préhension max. [N] | 600.0 |

| Poids de pièce recommandé [kg] | 3.0 |

| Longueur de doigt max. admissible [mm] | 165.0 |

| Poids de doigt max. admissible [kg] | 0.5 |

| Répétabilité [mm] | 0.05 |

| Temps de fermeture [s] | 0.7 |

| Temps d'ouverture [s] | 0.7 |

| Vitesse de rotation max. [mm/s] | 150.0 |

| Accélération max. [mm/s²] | 2500.0 |

| Poids [kg] | 2.63 |

| Température ambiante mini. [°C] | 5.0 |

| Température ambiant maxi. [°C] | 55.0 |

| Indice de protection IP | 46 |

| Catégorie salle blanche ISO 14644-1:2015 | 4 |

| Longueur X [mm] | 112.0 |

| Largeur Y [mm] | 100.4 |

| Hauteur Z [mm] | 121.0 |

| Electronique de commande | intégré(e) |

| Tension nominale | 24.0 |

| Interface de communication | PROFINET |

| Interface de paramétrage | USB |

| Puissance actuelle max. [A] | 2.5 |

| Courant de commande max. [A] | 0.5 |

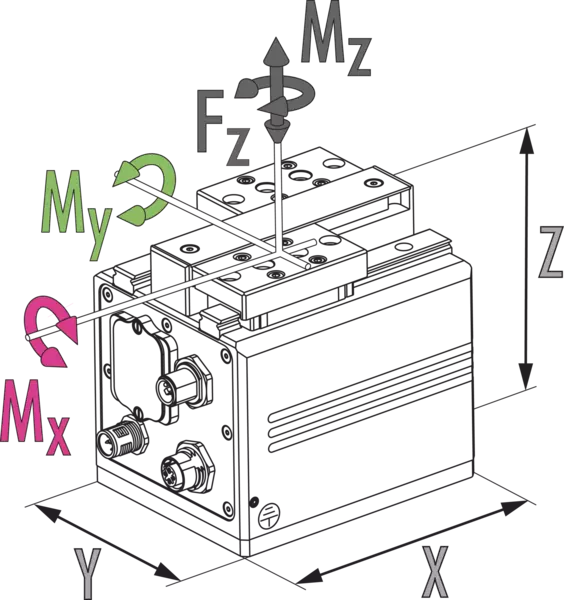

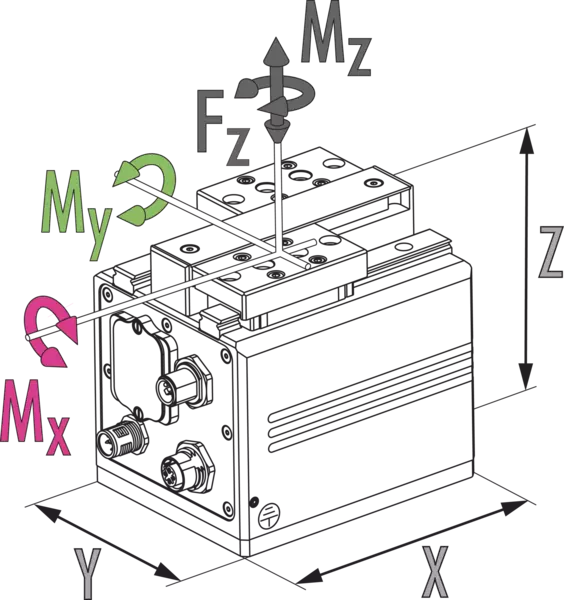

| Moment Mx max. [Nm] | 20.0 |

| Moment My max. [Nm] | 20.0 |

| Moment Mz max. [Nm] | 20.0 |

| Force axiale max. Fz max. [N] | 400.0 |

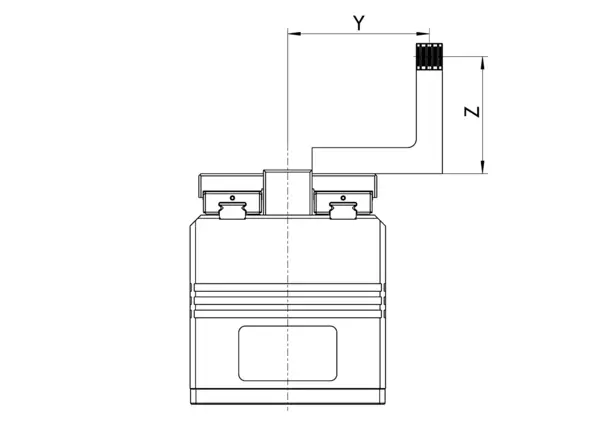

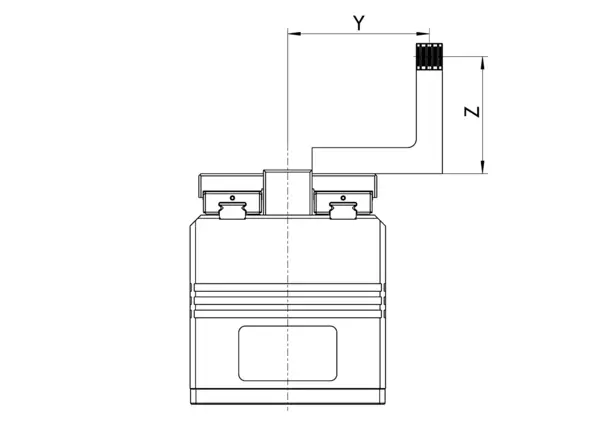

Dimensions et charges max.

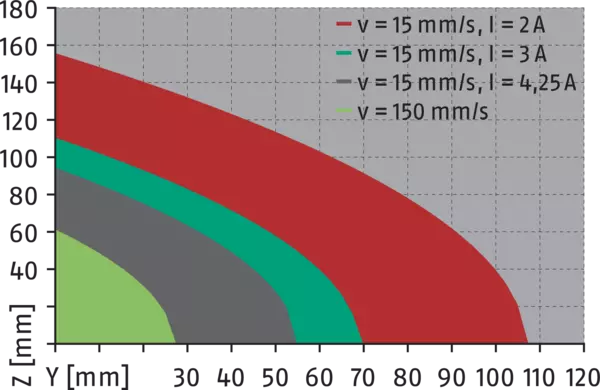

Dépassement maximum autorisé

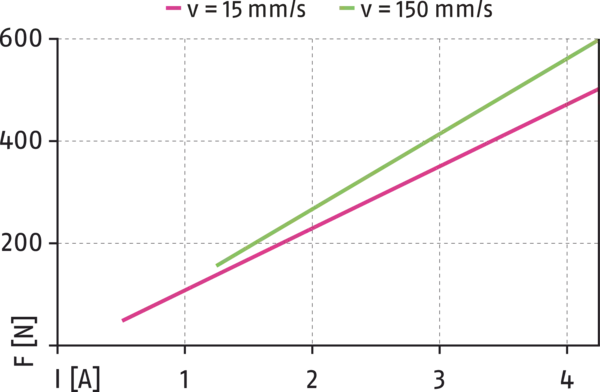

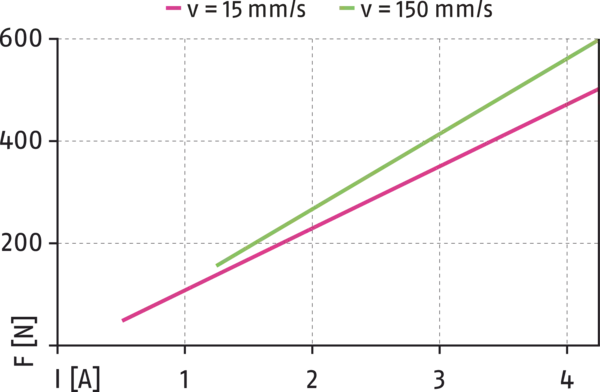

Force de préhension

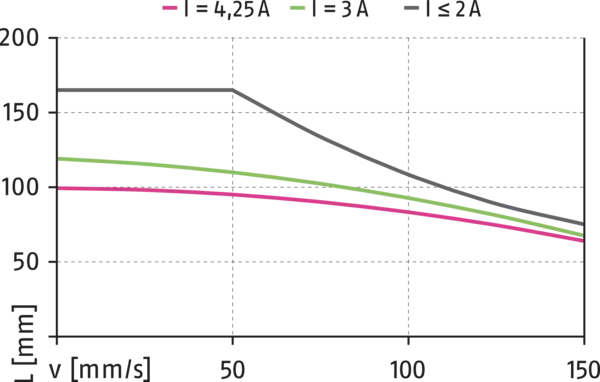

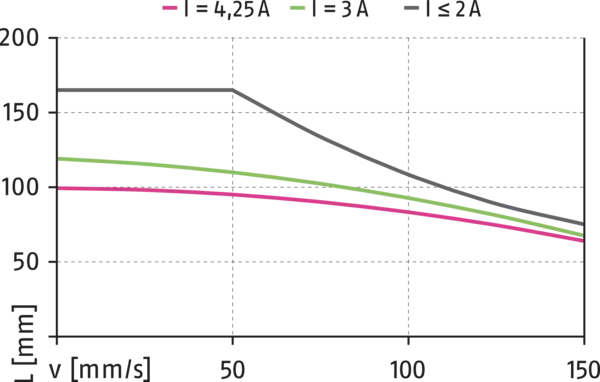

Longueur des doigts

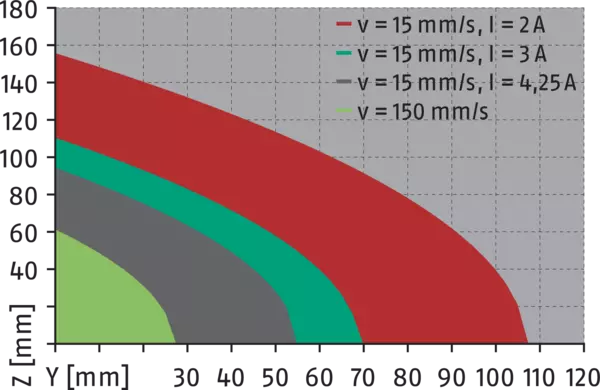

Dépassement maximum autorisé

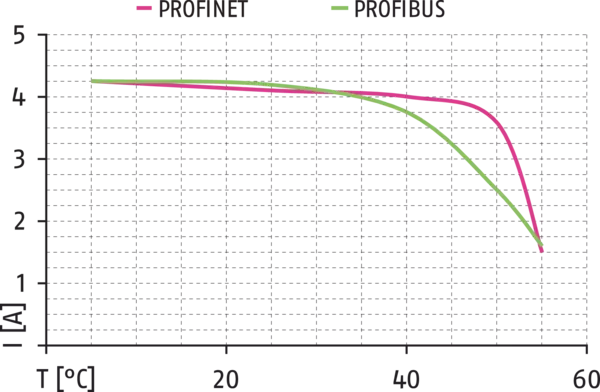

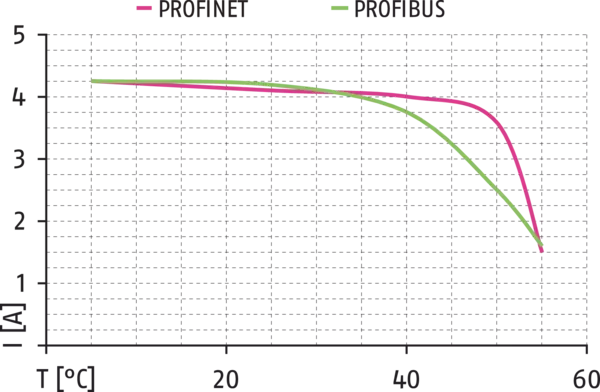

Déclassement

Dimensions et charges max.

Les moments et les forces indiqués correspondent à des valeurs statiques et s'appliquent à chacun des mors de base et peuvent survenir simultanément. Ils peuvent s’ajouter au moment produit par la force de préhension elle-même.

Dépassement maximum autorisé

Force de préhension

- X-axis:

- Courant moteur

- Y-axis:

- Force de préhension

Longueur des doigts

- X-axis:

- Vitesse des doigts

- Y-axis:

- Longueur des doigts

Dépassement maximum autorisé

- grey

- Plage non admissible

Déclassement

Le schéma d'étranglement indique le courant moteur maximal admissible selon la température ambiante.

- X-axis:

- Température ambiante

- Y-axis:

- Courant moteur

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

Minimum closing and opening times are merely the movement times of the base jaws or fingers at max. speed, max. acceleration, without current limitation (maximum current), and observance of the maximum permissible mass per finger.

Nominal currents

can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Electrical brake

The built-in, electric holding break is used for fixing and holding the position of the gripper jaws in the event of a power failure. It cannot cover all of the security or gripping force maintenance functions.

Operating principle

Rack and pinion principle

Housing material

Aluminum alloy, coated

Base jaw material

42CrMo4+QT

Actuation

servo-electric, via brushless DC servomotor

Warranty

24 months

Scope of delivery

Gripper including safety information and accessory kit with centering sleeves for gripper and finger mounting. Product-specific instructions and software can be downloaded at schunk.com/downloads-manuals and schunk.com/downloads-software.