For SCHUNK, practical, user-friendly automation solutions and efficient approaches for production of tomorrow are generally in focus. This self-image underlines the company also at the SPS and presents itself as a strong partner and companion for the challenges of modern manufacturing. SCHUNK helps users to make production processes more flexible, efficient and sustainable with smart components, digital services and comprehensive application knowledge,

The same applies for the smart gripper series EGU and EGK that will be showcased at the show. They are setting benchmarks in terms of flexibility, interface diversity and process reliability. As the grippers offer different gripping modes for different handling tasks. A new common electronics and software platform makes this intelligent feature come true. Because existing gripping methods are continuously optimized and supplemented, customers will continue to benefit from the future-proof enhancements via software updates.

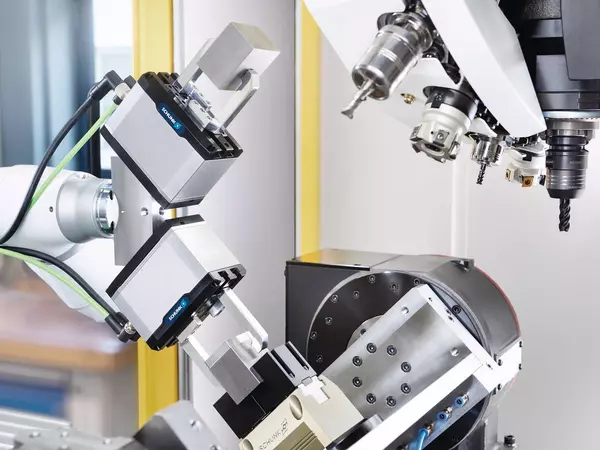

The EGK gripper for small components is excellently suitable for handling filigree and fragile workpieces, and therefore is ideally suited for challenging applications in the lab industry or electronics manufacturing. The universal EGU gripper is in turn a reliable all-rounder for all handling tasks. It plays to its full strength, especially in flexible loading and unloading of machine tools.

The linear direct axis of the SLD series are also dynamic all-rounders. This new generation with electrical linear direct drive is highly durable, ensures short cycle times and additional productivity during high-speed assembly and handling in electronics manufacturing, Life Science and E-mobility. There is a special focus on this industry topic: SCHUNK supports here with a forward-looking portfolio. For example, a combination of a high-speed linear module and a highly flexible double gripper has succeeded in reducing the automated setting of hairpin stators to one second and with a repeat accuracy of 0.01 mm!

Discover these and other practical solutions at the SCHUNK booth 11 in hall 3A.