If you want to speed up your production, there is no way around automation. Innovative, customized solutions are the cornerstone of healthy manufacturing in productive and economically successful companies. At AMB, the international exhibition for metalworking, we will be showcasing a wide range of automation options that make manufacturing processes more efficient and companies fit for the future.

Automation is the key to manufacturing productively and cost-effectively despite a shortage of skilled workers and cost pressure. But sensible automation doesn't just start with the machine. In order to fully exploit the machine's productivity potential, it is essential to ensure reliability and speed during loading and unloading. As a specialist in toolholding and workholding, gripping and automation technology, we offer an extensive portfolio of components that are required inside machines for automated manufacturing, as well as everything related to automated loading and unloading.

We are looking forward to the personal exchange with you!

Depending on your individual requirements for the workpiece, batch size, manufacturing process and machine, there are a range of options for implementing automated machine loading. We support you right from the beginning, and ensure that you understand the Machine Tending 101 and that you can use it in the best possible way. Based on our many years of experience, we work with you to find the right type of automation for your process, increasing the productivity of your machine tool with a view to sustainability and the future.

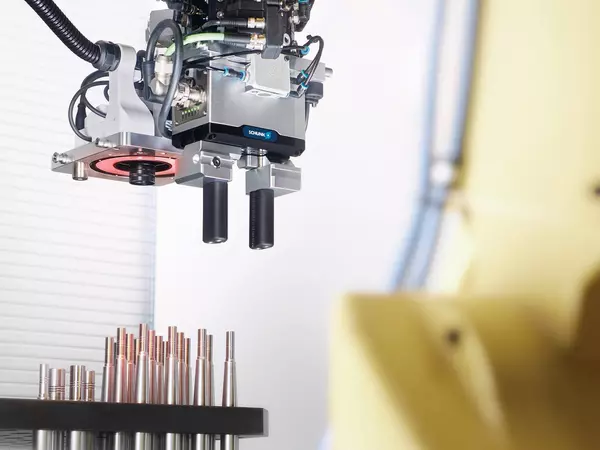

Experience the possibilities that automated workpiece handling offers with gripper and axis systems through illustrative examples. The successful mechatronic gripper series EGU for example, offers ideal options when it comes to flexible handling of a wide variety of workpieces. For AMB, we are expanding our portfolio to include a three-finger gripper especially for round workpieces.

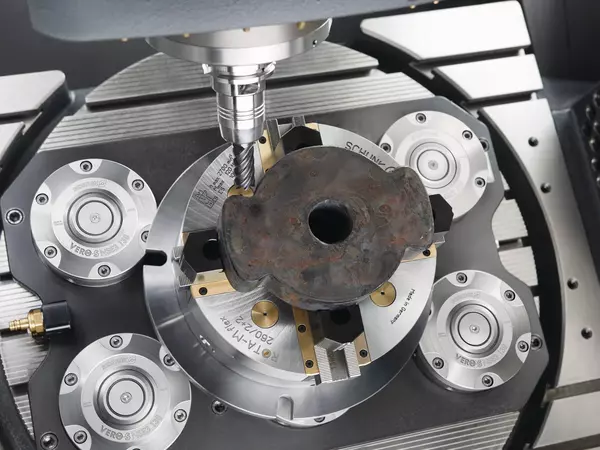

SCHUNK also offers manual, automatic and intelligent clamping solutions in almost any application for workpiece clamping. The existing product portfolio is constantly being optimized and expanded. Experience the diverse possibilities and fields of application for SCHUNK workholding technology with MAGNOS, TANDEM, KONTEC or VERO-S at the trade show

and experience the latest products such as the new ROTA-ML flex 2+2 , a flexible 4-jaw compensation chuck that is now up to 40 percent lighter.

At the AMB, experience how you can analyze and optimize processes with the iTENDO² and what applications are now possible through the new iTENDO² magnetic holder, which brings intelligent real-time sensor system directly into the machine room independent of any interfaces. We focus on your case of application, working together to find the optimal toolholding system for your task. Alternatively, explore our range of specialized solutions and our easyToolholder configurator, designed for scenarios where standard solutions fall short.

It is not always possible to fall back on a standard component. For this purpose we have the SCHUNK Engineering: From a simple adaptation to complex individual clamping or automation solutions that have to be developed from scratch, everything is possible. In addition to a personal conversation with our customer service team, our digital tools provide support for individual configuration: easyJAW (chuck jaws) easyToolholder (toolholder), FGR (gripper finger), ELG and PLG as well as the linear module configurator. Our tried-and-tested configurators offer special solutions with just a few clicks - this saves time and can be implemented at low cost.