It is likely that most drivers genuinely look forward to having their vehicle completely cleaned. Unfortunately, the beautiful shine only lasts for a short time, especially on the wheel rims, because brake dust quickly builds up again. The black coating is not only unsightly, but also harmful to health. The friction generated during each braking process produces abrasion with particles of various sizes – from fine dust with a particle size of less than 10 micrometers to ultra-fine dust with particles smaller than 0.1 micrometers, which enter the bloodstream via the lungs and can lead to respiratory and cardiovascular diseases. In order to reduce this potential hazard, fine dust emissions from the brakes are to be significantly reduced. The newly adopted Euro 7 emissions standard regulates all vehicle emissions – both exhaust particulates and abrasion from tires and brakes – and should apply to all newly registered passenger cars from the end of 2027. EMAG LaserTec has developed a new machine concept for production of the brake disks of the future, which applies a hard metal coating to the brake disk by laser deposition welding.

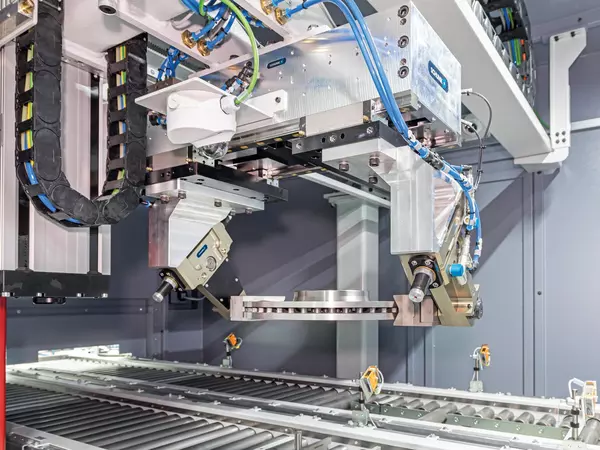

"We launched the ELC 450 LMD so that our customers can meet the requirements for the brake disk of the future. It uses "Laser Metal Deposition" (LMD) to apply a two-layer coating to the brake disk, which makes it practically impervious to wear and corrosion, while significantly reducing fine dust emissions," confirms Martin Fritz, Development Team Leader at EMAG LaserTec in Heubach. "SCHUNK provided us with significant support in realizing the automated component feed to the laser cell in a compact and reliable process, and with a specified cycle rate. The pneumatic long-stroke gripper PLG is used in conjunction with GFS universal swivel fingers – this is a convincing handling solution for us in the new machine." The EMAG design engineers installed the long-stroke gripper on a line gantry in the ELC. "We were able to dispense with a classic robot for component feeding, because there is no room for it in this cramped workspace," says Martin Fritz, explaining the ELC environment. "The existing linear handling from EMAG and the SCHUNK PLG gripper together with GFS swivel fingers result in ideal kinematics for the brake disk infeed and outfeed."

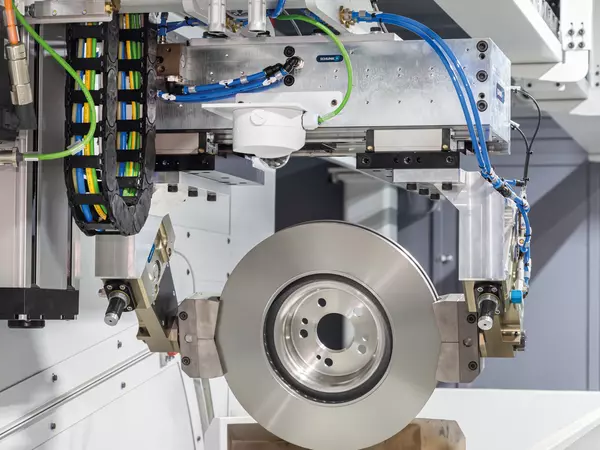

The compact loading and unloading solution in the workspace of the ELC 450 LMD DUO proves to be robust in operation of two laser cells. The PLG starts its work at the roller conveyor by picking up the pre-centered gray cast iron brake disk, which weighs around 30 kilograms. It will have been cleaned, weighed and preheated to about 300 degrees Celsius in upstream processes, and can be fed to the roller conveyor in manual, semi-automated or fully automated mode, depending on how the customer has structured their manufacturing. The PLG now guides the horizontal disk to the mounting spindle of the first laser cell. This is where the first layer, a stainless steel corrosion protection layer, is applied. After the hermetically sealed laser unit has released the disk, the PLG lifts it off the spindle and turns it using GFS swivel fingers before placing it back on the arbor. The second side of the disk receives its corrosion protection layer next. Then, when the first laser station has finally released the disk, the handling system moves to the next station above the suction funnel, which vacuums in metal dust residues. The disk is also turned over above the funnel, in order to vacuum it on both sides. Finally, the PLG feeds the disk horizontally to the second laser station, where the hard carbide layer is welded in, once again on the top and bottom sides.

In the two cells of the ELC 450 LMD DUO, the coating material is fed in as a powder and fused onto the component surface by laser. After a total of four coating processes – two disk sides and two cells - the brake disk is ready to be unloaded. EMAG has equipped the laser application processes with inline quality assurance measures, such as a coating thickness sensor that checks the coating thickness, meaning that it is guaranteed that nonconforming parts will be ejected from the process by a mechanism integrated in the process. The PLG brings the finished coated brake disks to the exit point from the ELC workspace on the corresponding roller conveyors for parts removal; downstream processes, such as grinding and cleaning, then take place.

"Our specifications for the gripper in this new machine concept were very clearly defined," summarizes Martin Fritz: a long stroke for a disk-shaped component with a diameter of 250 to 500 millimeters, force for a workpiece weighing around 30 to 50 kilograms, a gripping height of around ten to 45 millimeters, and sufficiently robust for an environment with residual metal dust. "The ELC's tight workspace set further constraints," says the Development Team Leader. "The solution has got to be compact. We want the component to be fed and discharged in a horizontal position, and the open gripper stroke always to move in the process direction. Freedom of setup across a defined range of workpieces is also a requirement, because we want to be able to grip all disk sizes with just one set of jaws. We also need safety: analog monitoring of the jaw stroke provides us with a way of knowing directly whether the correct workpiece is being gripped. And last but not least, swiveling should be quick."

A sophisticated machine concept for the brake disk production of the future requires equally sophisticated components. It quickly became clear that the newly introduced long-stroke gripper from SCHUNK was the right solution. "Configuring the gripper together with Jürgen Kolbus here at the desk made the work much easier, and saved a lot of time," confirms Martin Fritz. "It took only a few minutes, and we had our CAD. After less than an hour, we were able to see directly in the Design department whether everything fitted." Special solutions in industrial manufacturing are often associated with high costs and long delivery times. SCHUNK's quickly configurable product ranges are the answer to this problem: customers receive an individual, affordable solution quickly, even for small batch sizes and high demands. The GFS swivel fingers with a swiveling time of only 0.8 seconds were the final deciding factor for EMAG in choosing this solution: "The GFS fingers from SCHUNK were the best solution for the specific process," emphasizes Martin Fritz. EMAG installed the size 50 PLG in the ELC 450 LMD DUO, and met all the specifications with it.

A complete, fully automated process in the coating system takes just under four minutes. Avoiding set-up and idle times, 24/7 automation, fast cycle rates – for EMAG, the new laser application system must meet the high quantity requirements resulting from the entry into force of the Euro 7 standard. The PLG in combination with the GFS swivel fingers significantly supports this objective – both in terms of quality, safety and speed of the process.