Speed up your projects!

We combine our expertise with innovative technologies and sustainable thinking for your success

For the development of customized solutions, we offer a comprehensive range of services: deep industry expertise, an engineering process optimized over decades, and design authority over our broad, high-quality component portfolio. The ideal foundation for your success.

Solutions for your industry

In addition to its extensive portfolio of high-quality components for clamping, gripping and automation, SCHUNK offers a proven engineering process that has been optimized over decades for the development of customized solutions. This process is based on deep industry expertise, technical excellence, rapid implementation, and global availability in the areas of project management, design, production, assembly and after-sales service. The result: customized axis systems and assembly modules in the areas of pneumatics, mechatronics and robot accessories from a single source, all precisely tailored to the individual requirements of customers to optimally support their production processes.

Multiple cell-spacing gripper for handling prismatic battery cells

Assembly for handling solar module components

Double gripper unit for relocating rims

Customized solution for clamping crane hooks

Hydraulic compensation jaw with separate concentricity adjustment for clamping unround components

Hydraulic expansion arbor for clamping bladed discs

Four steps to project success

1. Understand challenges - define the requirements

From defining precise requirements through personal dialog to developing a concept with a reliable budget estimate.

2. Developing solutions – from idea to design

We work closely with you to develop customized solutions. This allows you to fully concentrate on your core competencies.

3. Manufacturing and assembly - production and validation

With our high level of manufacturing expertise and an end-to-end digital process chain, we ensure maximum efficiency and precision, worldwide.

4. On-site support – delivery and after sales

As a trusted partner, we take care of your concerns and support you every step of the way.

Our expertise – your advantage

- Target prices for our solutions for early planning security

- Industry expertise: analyzing processes and developing solutions

- Consulting in over 34 subsidiaries and 6 engineering hubs worldwide

- Everything from a single source: project planning, quotation, design, project management

- Rapid creation of solutions based on many years of industry expertise

- Fast and efficient error analysis and development of customer-oriented solutions

- Inspection, maintenance and repairs on site at the customer's location

- Global resources in project planning, design, and project management

- Know-how and resources for special components and assemblies as part of your system

- Fast adaptation of data and components throughout the entire process chain

- International engineering hubs with globally uniform production standards and processes

- Remote support for short-term assistance during commissioning

- Rapid deployment of technicians on site to resolve complex problems

Configure your solution –

Fast. Online. Customized

Configurable products

Our configurators offer the price, delivery time and validation with one click.

SCHUNK configurators are the fast, data-based entry into the SCHUNK engineering process. The SCHUNK configuration tools quickly lead to precise, application-related configurations without prior knowledge and use stored expert knowledge. Specific requirements give rise to precise specifications with characteristic values and CAD data that serve directly as a basis for work. SCHUNK Engineering takes these results, verifies them in the real application, makes any necessary adjustments and transforms them into a technically validated, ready-to-use solution. Our consultants will be happy to answer your requests personally.

- Individual customization: Specific requirements are taken into account directly.

- Expert knowledge integrated: Plausibility, compatibility and variant logics safeguard the preliminary design

- Immediately usable data: Direct download of CAD/documentation – available worldwide and in multiple labguages

- Consistency: Seamless transfer to SCHUNK engineering and integration in CAD/PLM for prototype to series production

Start configuring

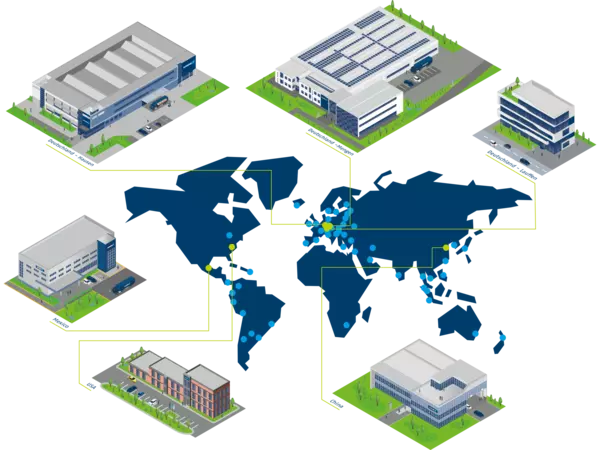

Worldwide, close to you

With 34 sales subsidiaries and 6 state-of-the-art engineering hubs worldwide, we are always close to our customers. Our global presence enables fast response times, personal advice on site and customized solutions. With combined know-how and regional expertise, we ensure your competitiveness – anywhere in the world.

Aerospace x SCHUNK Engineering

Tailored solutions for precise, reliable aerospace processes

We turn your requirements into custom gripping, clamping, and handling solutions—ensuring consistent quality, part protection, and robust process reliability.

Learn more