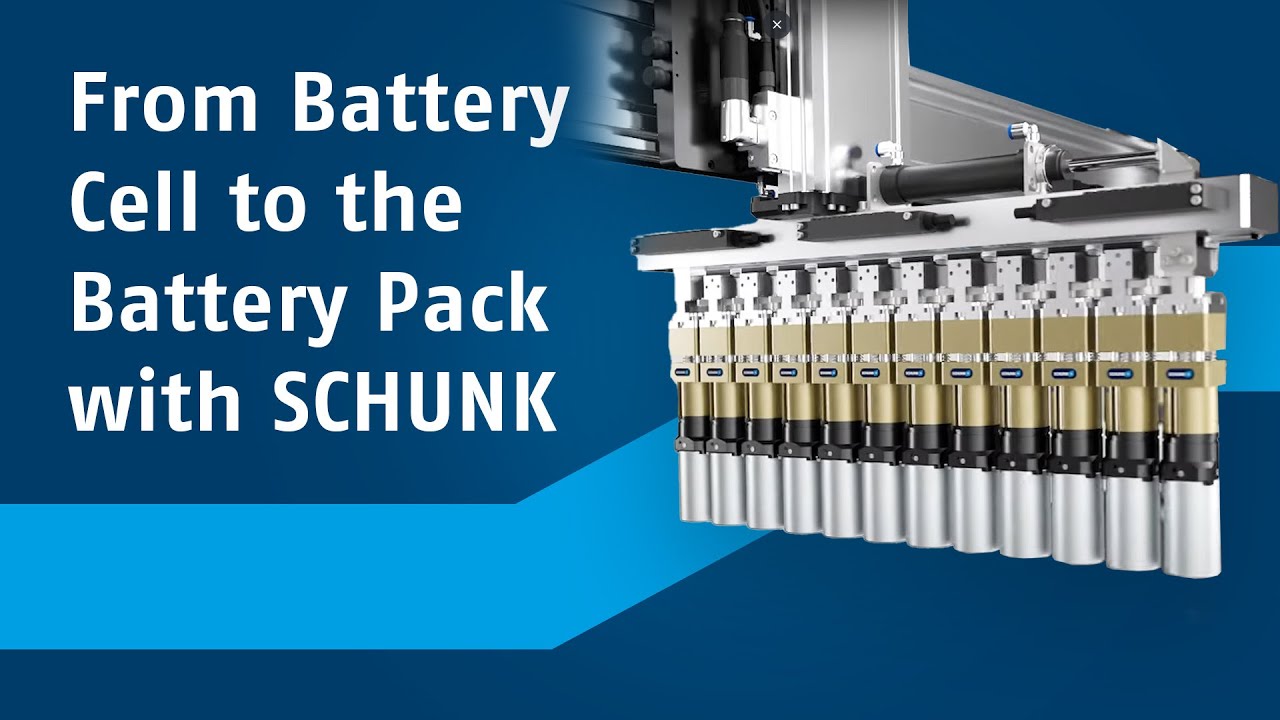

SCHUNK handles everything from the individual battery cell to the finished battery pack from one source. The combination of RCG round cell grippers and other SCHUNK components such as sensors, compensation units, cell spacing units and linear direct axes enables precise and dynamic processes. The RCG is tailor-made for your application and is individually scalable.

RCG

Round cell gripper

The round cell gripper RCG is a pneumatically controlled magnetic system with which a battery cell can be picked up and set down magnetically.

Handling 46 mm round cells with the RCG

The RCG round cell gripper has a pneumatically controlled magnet system with which battery cells and picked up and set down. The RCG is typically used in multiple gripping units, for example in a row arrangement or for gripping a complete cell cluster. Compact external dimensions of the single gripper enable maximum packing density.

Take advantage of the benefits

- Compact overall dimensions

the individual gripper enables maximum packing density of battery cells - Maximum process reliability

through sensory workpiece and status detection - Avoidance of workpiece loss

thanks to the integrated gripping force maintenance, even in the event of energy loss

- Protection of the battery cell

by means of an insulating layer between the gripper and the battery cell - Short project implementation times

as the RCG gripper, which is perfectly tailored to round cells, is a standard product

The automotive industry is facing a major upheaval – transitioning from the traditional combustion engine to E-Mobility. Find out more about our advanced concepts for the transition to battery technologies and electric drive systems.