Wire EDM

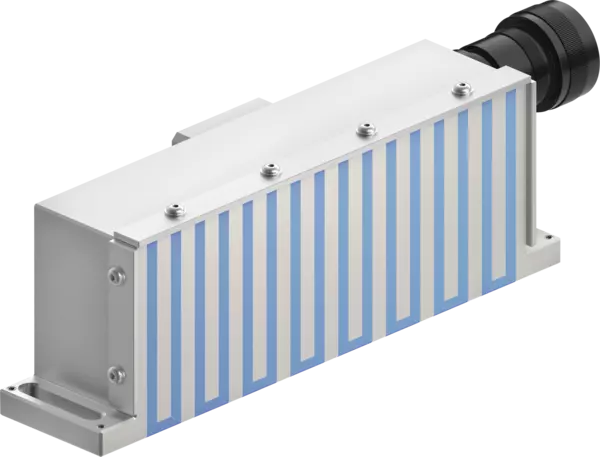

Magnetic chucks with parallel pole technology

Electropermanent magnetic modules with high holding forces specifically for EDM applications

Description

Advantages – Your benefits

- Innovative "fine" and "active" pole pitch

Provision of the required clamping force for clamping of very small workpieces (up to 20 x 20 mm) - Stainless steel frame

Avoidance of oxidation and expensive cleaning due to contact with air and chemical liquids - Even permanent magnetic clamping force across the entire workpiece

Low deformation and vibration clamping of the workpieces - Low vibration clamping

Improved surfaces and significantly increased precision - Deformation-free clamping

No deformation and internal forces in the workpiece due to the clamping force - State-of-the-art electropermanent technology for one-time energy supply for MAG/DEMAG process

Energy-efficient and reliable clamping of the workpieces - Clamping within a few seconds

Shortest possible setup times and a resulting increase in productivity - Control unit compatible with machine control system

Can also be used in automated applications - Mounting bores especially for EDM machines

The magnetic modules can be mounted directly on the machine table.

Options and special information

- Electropermanent magnetic modules for wire EDM

MAGNOS MEF magnetic modules are specially designed for EDM applications. An innovative "fine" and "active" pole pitch allows very small workpieces to be clamped while maintaining the holding force required for machining. Due to the unfavorable influences during eroding – caused by the chemical liquids and contact with air – the magnetic modules are made of special stainless steel. This prevents oxidation as well as expensive cleaning work on the modules. - The MEF magnetic modules are self-sufficient and require only a short pulse for the MAG/DEMAG process due to innovative electro-permanent technology. Specially prepared positioning holes allow quick and easy mounting on EDM machines without the need to drill separate holes beforehand.