CPS 210-A

ID 1590994

- Force Fz max.: 31000 N

Technical details

| Weight [kg] | 2.7 |

|---|---|

| Max. permissible XY axis offset [mm] | ± 2 |

| Max. permissible angular offset XY [°] | ± 0.7 |

| Max. permissible angular offset Z [°] | ± 1 |

| Tool-side connection | ISO 9409-1-125-6-M10 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 60.0 |

| Min. operating pressure [bar] | 5.0 |

| Max. operating pressure [bar] | 7.0 |

| Screw connection diagram | L side A/B/C/D |

| Mounting surface control module | Side A |

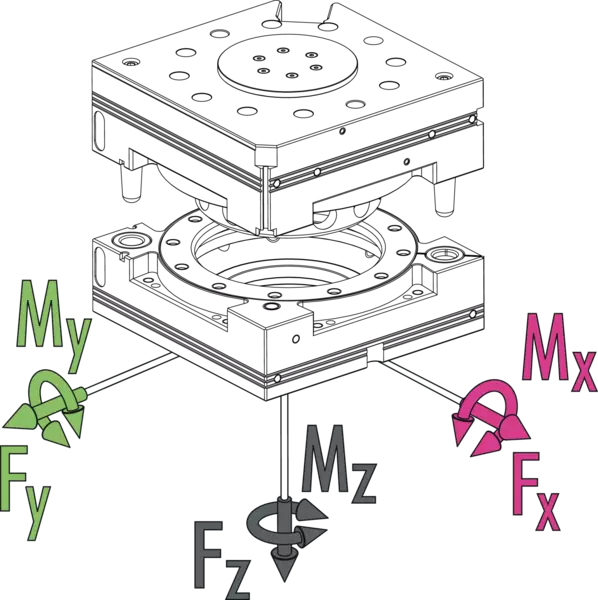

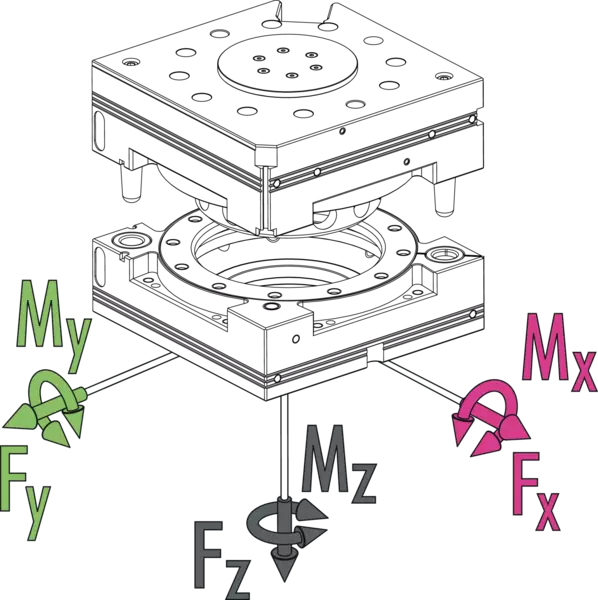

| Max. dynamic moment Mx [Nm] | 3500.0 |

| Max. dynamic moment My [Nm] | 3500.0 |

| Max. dynamic moment Mz [Nm] | 1800.0 |

| Max. static moment Mx [Nm] | 10500.0 |

| Max. static moment My [Nm] | 10500.0 |

| Max. static moment Mz [Nm] | 5400.0 |

| Force Fx max. [N] | 23500.0 |

| Force Fy max. [N] | 23500.0 |

| Force Fz max. [N] | 31000.0 |

| Force Fx max. dynamic [N] | 7800.0 |

| Force Fy max. dynamic [N] | 7800.0 |

| Force Fz max. dynamic [N] | 10500.0 |

Max. loads

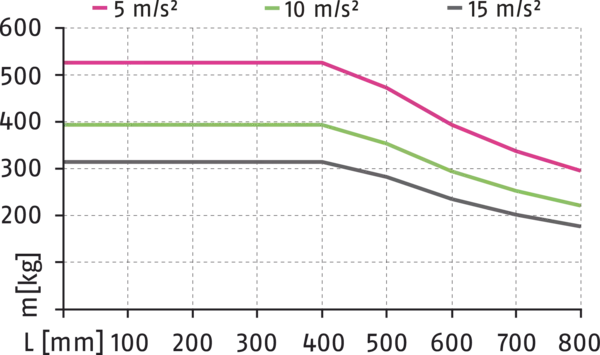

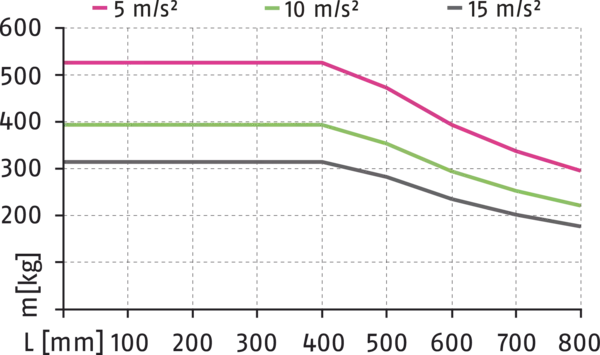

Load chart

Max. loads

This is the sum of all static loads that are permitted to act on the tool changer.

Load chart

- X-axis:

- Lever arm

- Y-axis:

- Load capacity

General notes about the series

Harsh environmental conditions

Please note that use under harsh environmental conditions (e.g. in the coolant area, cast and grinding dust) can considerably reduce the service life of the units, and we will not take over any warranty. However, in many cases we can find a solution. Please contact us for assistance.

Minimum pressure

The minimum pressure is the required minimum pressure to lock the system. This pressure must be continuously present during operation.

Self-retaining

The automatic tool changer has a self-retaining feature that prevents the tool from falling off in case of the pressure drop. The change master and change adapter can be separated by pneumatically actuating the piston.

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

piston-actuated balls with integrated spring (to support the locked piston position)

Media transmission

variable via attachment feed-through modules, depending on the unit size

Housing

The housing consists of high-strength, hard-coated aluminum alloy The functional components are made of hardened corrosion free steel.

Warranty

24 months

Service life characteristics

on request