JGP-P

Função

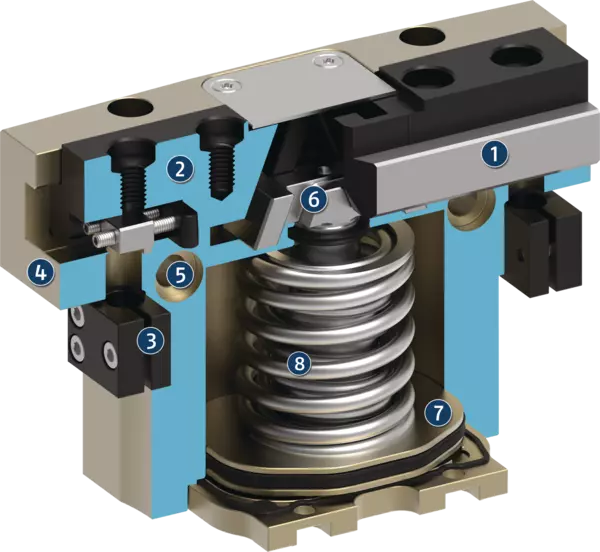

Sectional diagram

Sectional diagram

The piston is moved up and down by compressed air.

The angled active surfaces of the wedge-hook produce a synchronized, parallel jaw motion.

- 1

-

T-slot guidance

loadable, robust base jaw guidance for extremely long gripper fingers - 2

-

Base jaw

with standardized screw connection diagram for the connection of the workpiece-specific gripper fingers - 3

-

Bracket for sensors

Brackets for proximity switches and adjustable control cams in the housing - 4

-

Housing

is weight-optimized due to the use of high-strength aluminum alloy - 5

-

Centering and mounting possibilities

for universal assembly of the gripper - 6

-

Wedge-hook design

for high power transmission and minimal wear as a result of larger diagonal pull surfaces - 7

-

Piston

Maximum force through maximum surface of drive piston

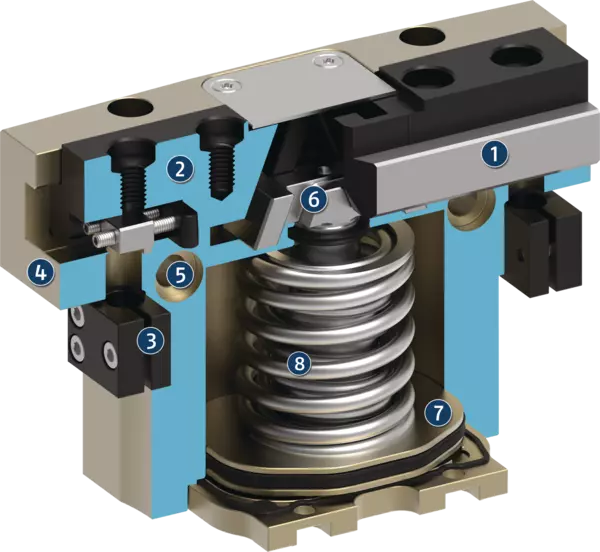

Gripping force maintenance version AS/IS

Settings of the control cams during monitoring with inductive proximity switches

Optional mounting possibility under the cover sheet for customer-specific additional structure

Gripping force maintenance version AS/IS

The mechanical gripping force maintenance device ensures that a minimum clamping force will be applied even if there is a drop in pressure. In the AS version this acts as a closing force, and in the IS version as an opening force. The image shows the AS version. The gripping force maintenance can also be used to increase the gripping force or for one-way gripping.

- 1

-

T-slot guidance

- 2

-

Base jaw

- 3

-

Bracket for sensors

- 4

-

Housing

- 5

-

Centering and mounting possibilities

- 6

-

Wedge-hook design

- 7

-

Piston

- 8

-

Gripping force maintenance

Settings of the control cams during monitoring with inductive proximity switches

Monitoring with inductive proximity switch can be performed as standard from size 64. In delivery state, the positions "gripper open" and "gripper closed" are preset with the control cams. The inductive sensors must be ordered separately and are slid into the housing up to the stop and clamped.

In order to monitor any other position, such as "workpiece gripped" for example, both control cams can be individually set in the respective base jaws.

- 1

-

Control cam preset for "gripper closed" position

- 2

-

Control cam preset for "gripper open" position

- 3

-

Holder with clamping screw for fixing the sensor

- 4

-

Clamping screw for process-reliable fixing of the adjusted switching point

- 5

-

Adjusting screw for setting any switching point

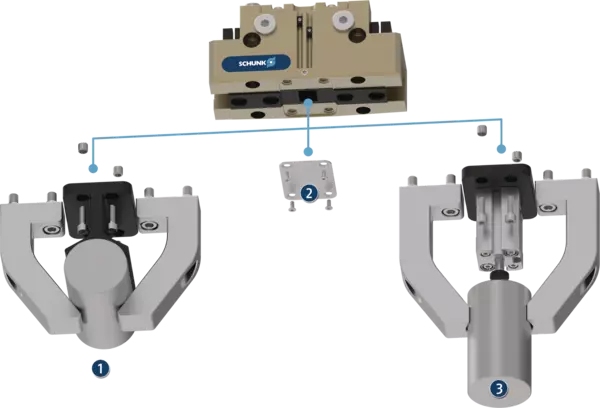

Optional mounting possibility under the cover sheet for customer-specific additional structure

In delivery state, a cover sheet is mounted to the gripper. This can be removed if necessary. Under the cover sheet are threads and fittings for mounting customer-specific designs for implementing additional functions.

- 1

-

Centralização ou suporte adicional da peça

- 2

-

A placa de cobertura (pode ser removida)

- 3

-

Ejetor com cilindro externo acoplado à garra

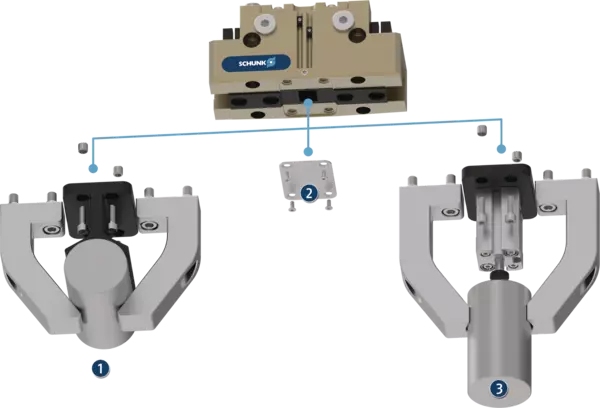

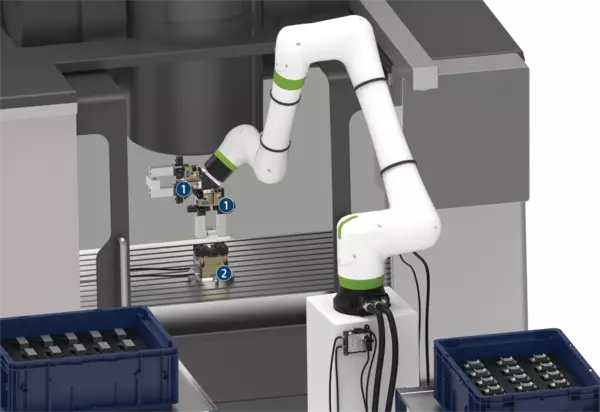

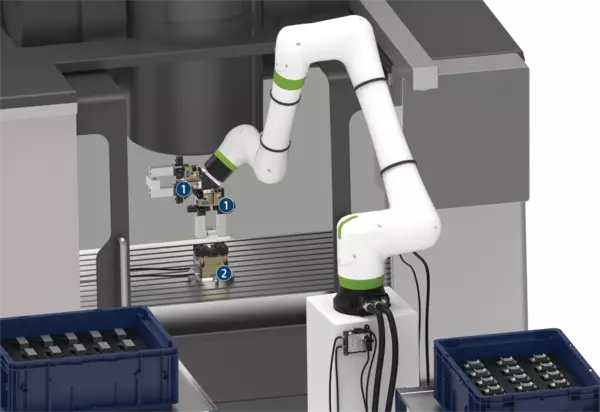

Exemplo de aplicação

Exemplo de aplicação

Carga e descarga de uma máquina-ferramenta otimizada para o tempo de ciclo. Ao usar duas garras no robô, a máquina-ferramenta pode ser carregada automaticamente de maneira otimizada para o tempo de ciclo e a produtividade pode ser aumentada. Após a remoção da peça acabada da primeira garra, a morsa acionada automatizada é limpa de lubrificante de refrigeração e cavacos através do bocal de sopro integrado da garra dupla. Depois disso, a segunda garra pode inserir diretamente a peça não usinada e o processo de usinagem pode ser iniciado. A peça acabada é então depositada e a próxima peça não usinada é coletada novamente em paralelo com a usinagem da peça.

- 1

-

Garras paralelas de 2 dedos JGP-P

- 2

-

Morsa acionada TANDEM PGS3