Digital technologies make it possible to make manufacturing processes more energy-saving, efficient and flexible. They are key building blocks for a "Healthy Factory" - with healthy and economically successful production. With this goal in mind, SCHUNK is also making its clamping devices increasingly configurable and networkable. The advantages are particularly evident in the processing of small and medium batch sizes and in transparent process monitoring. For this purpose, SCHUNK has added an electrically driven version with a freely programmable clamping stroke to its proven 5-axis clamps within the KSX series - the KONTEC KSX-E.

The new KONTEC KSX-E is controlled with 24 V DC via spring contacts on the floor or with a cable-connected plug connection on the side. All programmable parameters such as the clamping force, clamping stroke or jaw position can be simultaneously monitored and transferred to machine control via the integrated IO-Link interface, where it can be analyzed. IO-Link is a fieldbus-independent point-to-point connection, whereby the clamping device can be integrated into the corresponding fieldbus system via an IO-Link master. In future, it should also be possible to transmit and data to an app and configure it wirelessly or via cable.

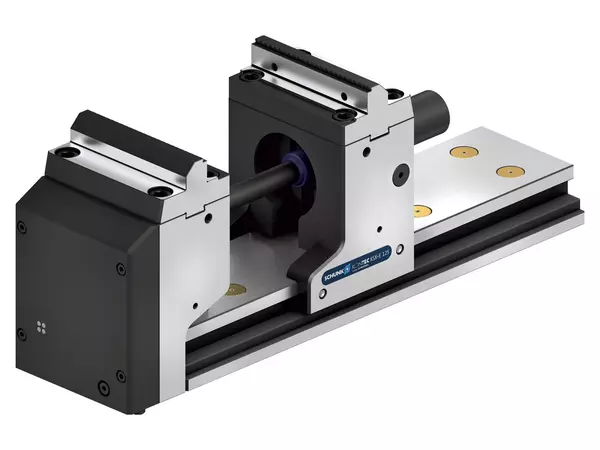

A large clamping range of up to 420 mm and jaw pre-positioning make the KONTEC KSX-E particularly flexible for automated machine loading with high part variance. Due to its geometry with very high jaws, the vise ensures optimal accessibility for 5-sided complete machining on 5-axis machines. The top-mounted spindle ensures that the clamping force is applied directly below the workpiece, thus preventing the jaws from lifting up. The infinitely programmable clamping force of up to 40 kN per jaw ensures that the workpiece can be clamped reliably and without vibration, even with minimal clamping surfaces. The vise works reliably even under the influence of chips, dirt or coolant. Thanks to its complete sealing and metal housing, the electronics and actuators are also optimally protected.

The comprehensive portfolio of system and top jaws from SCHUNK rounds off the overall package of the KONTEC KSX-E. Suitable clamping jaws are easy to find using the digital SCHUNK clamping jaw quickfinder. SCHUNK will be offering the KONTEC KSX-E in size 125 from the first quarter of 2025.