The industry faces the challenge of producing responsibly, flexibly and efficiently at the same time. Today, the development of new products and the manufacturing concepts required for this must be realized much faster and must be flexibly adaptable in terms of variants and variables. The industrial metaverse creates a virtual, interoperable digital space for this purpose. Automation concepts can already be planned, extensively tested and optimized here - much faster and more comprehensively than would ever be possible in the real world. Virtual simulation not only speeds up the development of new products and systems, but also reduces commissioning times, production downtime and time-consuming corrections. SCHUNK also uses this to develop new digital components and drive technological progress in all areas of automation.

Digital twins for flexible production

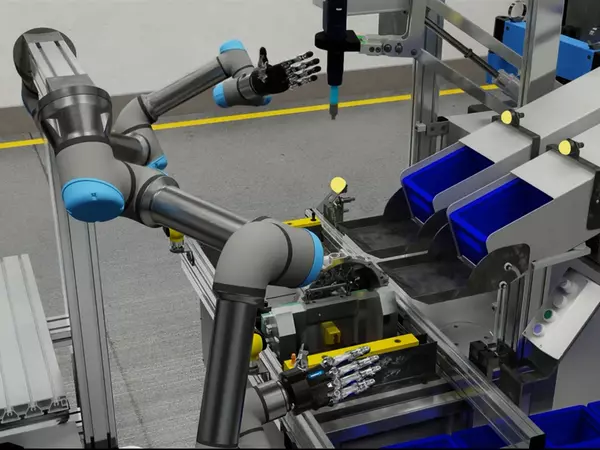

Every simulation starts with a digital twin; a digital image of a real object or process. It can be used to simulate new processes and the interaction of the involved process modules in real time. When developing true-to-life digital twins, SCHUNK follows a five-stage plan: Each stage brings the components and assemblies from toolholding and workholding, gripping technology and automation technology closer to the perfect digital image. This not only records the electrical properties and interfaces of the products, but also their physical behavior such as force, friction coefficient or wear. The company has already digitally described the complete physical behavior of its first products, including new mechatronic parallel and centric grippers. SCHUNK sees particularly high added value in the further development of its AI-supported modules. The AI deployed in the HERMES-AWARD-winning 2D Grasping Kit is trained in the industrial metaverse using specific tasks to open up new areas of application in intelligent handling.

Rethinking virtual realities

As a technology pioneer, SCHUNK is pursuing a clear vision: to simplify the initial step towards automation for its customers. "By simulating automation tasks, we can very quickly offer them a sophisticated and highly productive solution that is optimized for their production tasks," says Timo Gessmann, CTO of SCHUNK. "Thanks to AI, we can greatly simplify the engineering. With the help of digital tools and simulations, all variants can be digitally validated within a very short time. SCHUNK relies on technology partnerships for the development of digital services. For example, the company uses tools such as ISG Virtous or the NVIDIA Omniverse for the simulation and project planning for complex automation projects.

The company is utilizing partnerships such as that with NVIDIA as a catalyst for the development of AI-based solutions in the area of simulation and production optimization. Through simulations in the industrial metaverse, SCHUNK creates synthetic data that supports the training of AI models. At the NVIDIA GTC in March 2025, the leading developer conference for artificial intelligence, SCHUNK and Schaeffler presented a simulated assembly application developed in partnership in the field of robotics, in which the SVH 5-finger hand developed by SCHUNK inserts screws into a housing. The application shows how the boundaries of intelligent automation can be extended and deployed in industry. For every type of robotics, from industrial robotics to Cobots and humanoid robotics, SCHUNK offers suitable end-of-arm components as well as compatible digital modules.