Flexibility is the key to modern automation - and SCHUNK supplies the right solutions. The technology pioneer is expanding its future-proof end-of-arm portfolio for robot applications, manufactured by SCHUNK in Germany. The portfolio covers the area between the robot flange and the end effector and can be flexibly adapted to individual requirements. The company is thus setting the course for the future and at the same time building on decades of experience in automation technology.

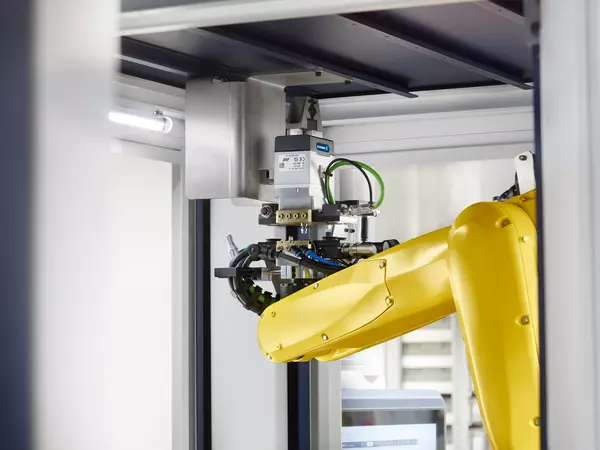

With a tool changer, robots are able to carry out different handling or processing tasks flexibly and without additional set-up work. They can be used to replace grippers, tools and other end effectors quickly and easily. This keeps downtime to a minimum. The Robot PLUS portfolio currently includes three different products in this area.

The two tool changers, CPS and CPB, are suitable for industrial applications. They replace end effectors fully automatically using pneumatics. In addition, they enable versatile media transfer by means of a wide range of signal, pneumatics, fluid and communication modules.

The CPS tool changer is a flexible all-rounder in which the master (CPS-K) and adapter (CPS-A) are connected positively and reliably via compressed air using a ball-bearing mounted locking mechanism. The system enables the fast and reliable changing of grippers and other tools with a handling weight of up to 1,000 kg. As hardened steel is used for all functional parts, it is particularly suitable for use in harsh machine environments. The series comprises 18 sizes and thus offers the right changer for every robot. When replacing an existing SCHUNK changer, users do not need to reteach, as the CPS is fully compatible.

The CPB tool changer offers efficient tool changes and therefore maximum flexibility and process reliability. The special feature of the CPB is its robust locking mechanism with bolts. Here, SCHUNK has applied its more than 20 years of experience in stationary clamping technology in the development and has thus transferred the proven system from the machine table to the robot. The form-fit locking, self-retaining bolt mechanism made of vacuum-hardened stainless steel offers maximum stability and a long lifespan. The integrated ISO interface also enables fast assembly and reduces the effort required during commissioning.

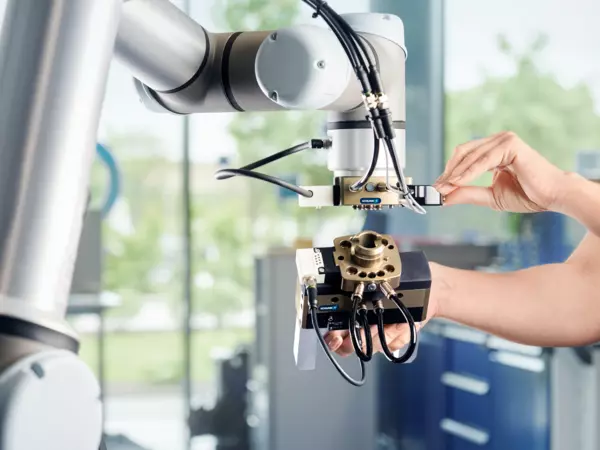

The CMS manual change system is the optimal additional for the most varied of tasks in production, handling technology, or at assembly workstations. The small, convenient system enables a quick change at the robot front end. The CMS can be locked and unlocked easily and with minimal effort thanks to proven push lever technology, without additional tools. It can handle loads of up to 58 kg. The integrated monitoring sensor system ensures additional operational and process reliability. Thanks to the ISO flange pattern the CMS can be mounted on all common robot types without the need for an additional adapter plate.

The AGM compensation unit effectively compensates for tolerances in automated processes with robots. For example, constrained situations when loading and unloading machine tools, inaccuracies in joining processes or jamming during bin-picking can be avoided. The modular AGM product family comprises 23 different sizes, meaning there is no need to compromise with regard to the interfering contour. With a wide range of variants, users will always find the right unit for every requirement. The AGM also scores highly in terms of compensation behavior: it can compensate for movements in all directions (XY, Z, W) and in combinations thereof (XYZ, WZ). The large load range, from just a few grams to over 400 kg, is particularly impressive. The patented spring and air cartridges enable reliable weight compensation, even in a horizontal or inclined position, while the stable and robust guides ensure a long lifespan.

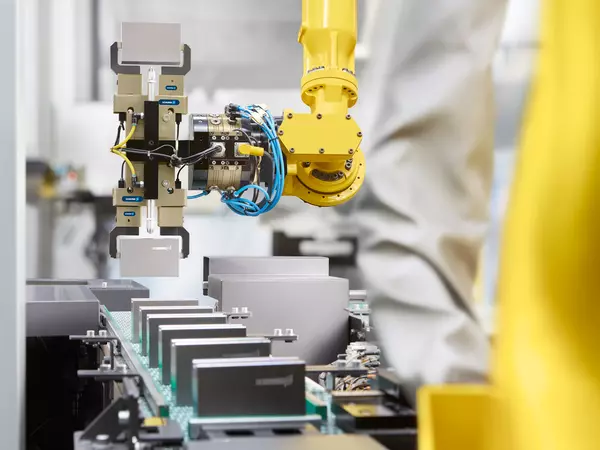

Whether quality control, for example in battery production for e-mobility, process monitoring or in grinding and assembly processes - the FTS 6-axis force/torque sensor detects process forces and torques with high resolution and precision. The sensor reliably evaluates the acting forces. Continuous monitoring leads to precise results and consistent quality in production. Featuring an IP67 protection class rating, the FTS sensor in nine sizes offers reliability, even under challenging conditions. The interface box with interfaces for EtherNet/IP, EtherCAT and PROFINET enables simple integration into existing systems.

With the Robot PLUS portfolio, SCHUNK creates versatile design options for flexible robot automation. Thanks to its decades of expertise in the development of custom-fit, sophisticated automation components, SCHUNK is synonymous with particularly high productivity, flexibility and resource conservation.