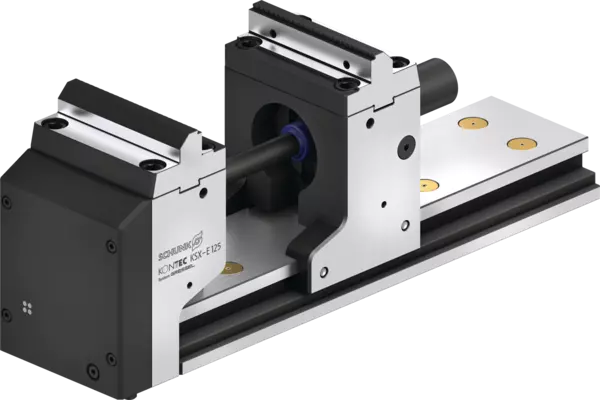

KSX-E IOL

5-axis clamping vise

Electrically driven 5-axis vise with continuously programmable clamping stroke for digitalized process monitoring.

Description

Advantages – Your benefits

- 5-axis accessibility thanks to high jaws

Allows the workpiece to be machined from five sides - Powerhouse with 40 kN clamping force per jaw

For vibration-proof clamping in a reliable process, even with minimal clamping surfaces - Perfectly suitable for automation

Thanks to the electromechanical drive and fully integrated sensor and actuator systems - Integrated sensor and actuator systems

No additional interfering contour - Control via IO-Link

For easy integration in commonly used fieldbus systems - Maximum process reliability

Thanks to various query options and transmission of error messages - Continuously programmable clamping force

Maximum flexibility in terms of workpiece size and workpiece material - Continuously programmable clamping stroke and jaw pre-positioning

Clamping ranges individually adaptable to the workpiece - Extendable clamping range

Enables clamping of various workpiece lengths - Spindle on top

Prohibits a rear up of the jaws - Wide range of applications

Suitable for rough and finished parts machining - Wide jaw program

Optimal adaptation to new clamping tasks

Options and special information

- Digital process monitoring

The digitalization of clamping devices will also have an increasing impact on clamping devices over the coming years, as these offer clear advantages, especially when machining medium and relatively small lot sizes with automated parts handling and comprehensive process monitoring. The new electromechanically driven 5-axis vise KONTEC KSX-E IOL has now been developed precisely for this purpose. Activated by 24 V DC, the new vise can be used to program and continuously adjust the clamping force up to 40 kN per jaw. The large clamping range of up to 420 mm with jaw pre-positioning makes the KONTEC KSX-E IOL a very flexible clamping device, especially in this field of application. All programmable parameters can also be transferred to the machine control and evaluated via the integrated IO-Link interface. - Optimum 5-sided accessibility

Due to its geometry with very high jaws, the vise ensures optimal accessibility for 5-sided complete machining on 5-axis machines. The top-mounted spindle ensures that the clamping force is applied directly below the workpiece, thus preventing the jaws from lifting up. The vise works reliably even under the influence of chips, dirt or coolant. Thanks to its complete sealing and metal housing, the electronics and actuators are also optimally protected. The extensive portfolio of system and top jaws from SCHUNK rounds off the overall package of the KONTEC KSX-E IOL