Plasser & Theurer's tamping units are essential components when it comes to the stability of track systems. The hydraulic and pneumatic cylinders required for this previously had to be processed on several machines with different set-ups. The company has invested in a state-of-the-art, automated production solution in order to manufacture these more efficiently. The aim was to focus on a single system, reduce changeover times, and enable both individual and series production in a flexible manner.

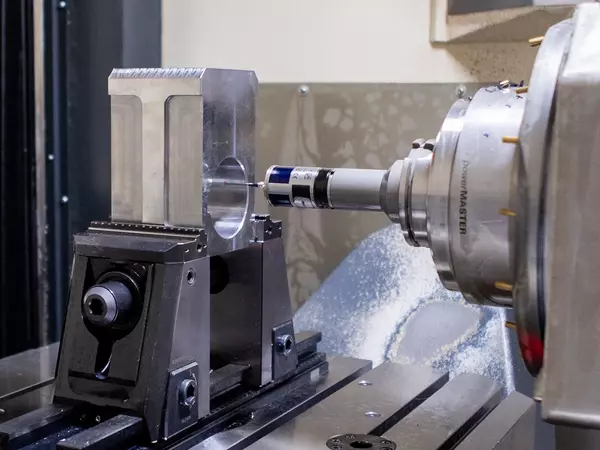

Plasser & Theurer decided on a production concept based on a DMU 85 H 5-axis machining center from DMG Mori, combined with the PH Cell 2000 modular pallet circular storage system. The workpiece clamping systems from SCHUNK play a decisive role in the efficiency of this solution.

The key part of the project was the close cooperation with SCHUNK. "We have already had good experiences with SCHUNK in the past and knew that we needed a customized solution for this project," explains Jürgen Punzenberger, Team Leader in Mechanical Manufacturing. Within a very short time, a concept was developed together with the experts from SCHUNK that is both economically and technically convincing. "With 5-axis vises for single part production, tombstones for multiple clamping and special custom clamping jaws, we have developed a concept together with SCHUNK that optimally meets our requirements and at the same time offers maximum flexibility. The sophisticated clamping technology allows us to efficiently process both individual parts and series parts," Punzenberger continues.

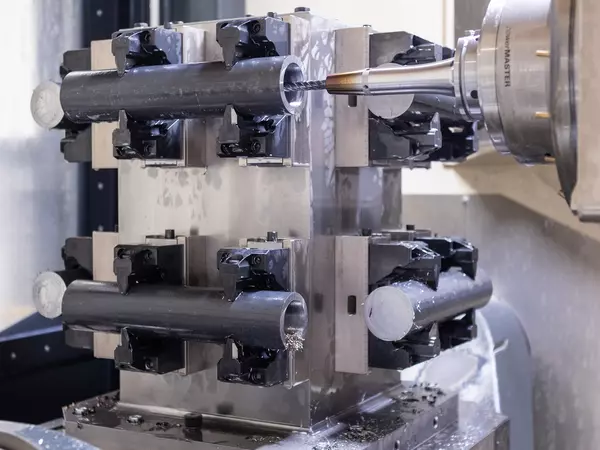

"SCHUNK is a strong partner, not least when it comes to customized solutions. We offer the broadest portfolio of standard clamping technology on the market, along with decades of experience in designing and manufacturing custom components. This enables us to realize economical and, above all, technically optimal solutions for our customers," says Raffael Baumgartner, Technical Sales Clamping Technology at SCHUNK, explaining why SCHUNK is the right partner for such complex projects. His colleague, Sokha Hem, emphasizes the combination of standard and special solutions: "We rely on a mix of proven standard centric clamps and individually adapted special jaws tailored to the component contours of the cast parts. This means we can guarantee maximum flexibility and machine utilization."

According to Sokha Hem, the KSC3 centric clamp series used on the tombstones is ideal for demanding clamping solutions with jaws with a large overhang (projection). To ensure maximum precision, the slides are individually adjusted to guide each vise. "This lapping of the already long slides into the base body ensures excellent jaw support, ensuring maximum repeat accuracy even with high clamping forces." The fully nickel-plated, and therefore corrosion-protected, base body, the backlash-free bearing and the encapsulated spindle of the maintenance-free clamping vise also ensure consistent clamping forces for reliable and precise continuous use. SCHUNK also offers the world's largest portfolio of chuck jaws, thus enabling rapid adaptation to new clamping tasks.

The KONTEC KSX-C2 5-axis vise combines several advantages for flexible 5-axis machining: excellent accessibility from all sides, tool-free jaw quick-change system, fully enclosed spindle with a basic clamping stroke of 130 mm and a spindle quick-change system. The integrated jaw quick-change system enables particularly fast changeover and thus increases efficiency. "The absolute highlight is the vise's active jaw pull-down, which is integrated as standard. By clamping both support jaws, precision clamping is activated and enables the complete and precise machining of the sixth side without additional conversion measures," emphasizes the clamping technology expert SCHUNK.

Raffael Baumgartner especially wants to emphasize the holistic approach adopted for the project: "In addition to the machine selection, the design of the tools and the clamping situation were simultaneously taken into account. This meant that no compromises had to be made." Thanks to the intensive exchange between the project partners, a solution was developed that was precisely tailored to the respective requirements. "I think this project in particular shows very well how crucial the right clamping technology is for economical machining," emphasizes Baumgartner.

The new production concept offers Plasser & Theurer numerous advantages. "We were able to increase our productivity by around 30% and maximize machine running times," explains Punzenberger, adding: "Due to the long autonomy times, we also switched to multiple machine operation." Another benefit is the reduction in changeover times. Thanks to the modular clamping devices, Plasser & Theurer can switch between different components with minimal effort. Cube clamping, for example, enables efficient multiple clamping, while the double-angle clamping solution secures larger components.

With state-of-the-art, automated 5-axis machining technology and customized clamping solutions from SCHUNK, Plasser & Theurer has succeeded in raising flexibility and productivity to a new level. "We are highly satisfied with the solution and will continue to rely on SCHUNK's expertise in future projects," concludes Jürgen Punzenberger, full of praise.