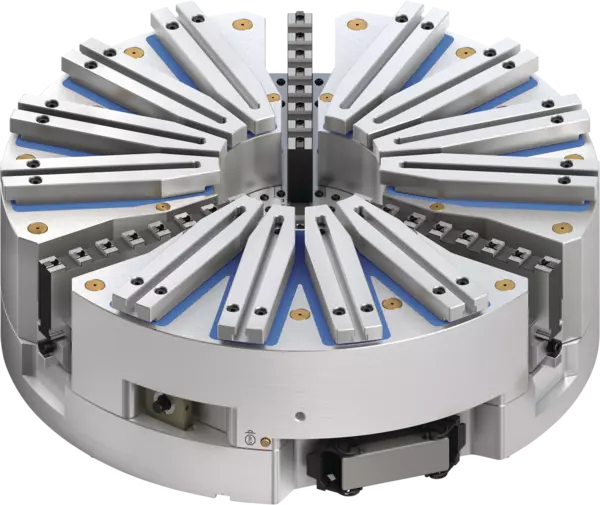

ROTA NCML

Hybrid chuck with manual workpiece centering

Hybrid chuck, which combines the advantages of centering via a 3-jaw manual lathe chuck and deformation-free clamping of the magnetic clamping technology of all ferromagnetic components.

Description

Advantages – Your benefits

- Workpiece centering via manual 3-jaw wedge bar chuck

No manual alignment of the workpiece is necessary - Deformation-free magnetic workpiece clamping

For maximum radial and axial run-out tolerances - High magnetic holding forces

Depending on the workpiece geometry and material, a high cutting performance is possible - For internal and external centering

For universal and flexible use - Optimal dirt sealing, encapsulated centering chuck

Low maintenance and ensured high clamping accuracy - Standard interface for centering jaws

Centering jaws can be manufactured from SCHUNK standard jaws - High clamping force due to jaw support

Improved cutting performance, particularly during hard turning - For grinding and hard turning

Ideal for high-precision workpiece machining - For horizontal and vertical machines

Suitable for use with almost every machine tool (turning – milling – grinding) - 3-sided machining possible due to retractable jaws

Reduced set-up costs, shorter processing times

Options and special information

- Low-deformation clamping of rings and fitting disks

The ROTA NCML is a combination of manual lathe chuck and magnetic clamping chuck. The manual lathe chuck serves to center the workpiece on the chuck and then clamps it via the magnetic clamping chuck without deformation and vibration. Double AlNiCo magnets are integrated in the magnetic chuck, which allow for demagnetization of the workpiece after machining. - The hybrid chuck is controlled via a control unit or directly via the machine control system. The workpiece can also be lifted from the chuck using pole extensions, and then milled from three sides.