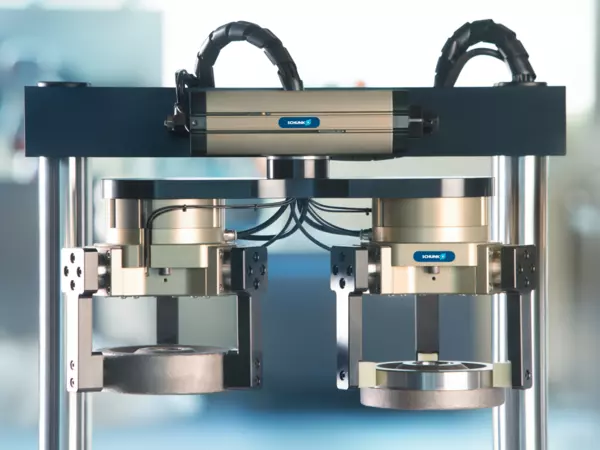

SRM 可以配备介质通道和电气通道,直接为气动和电动机械手供能。

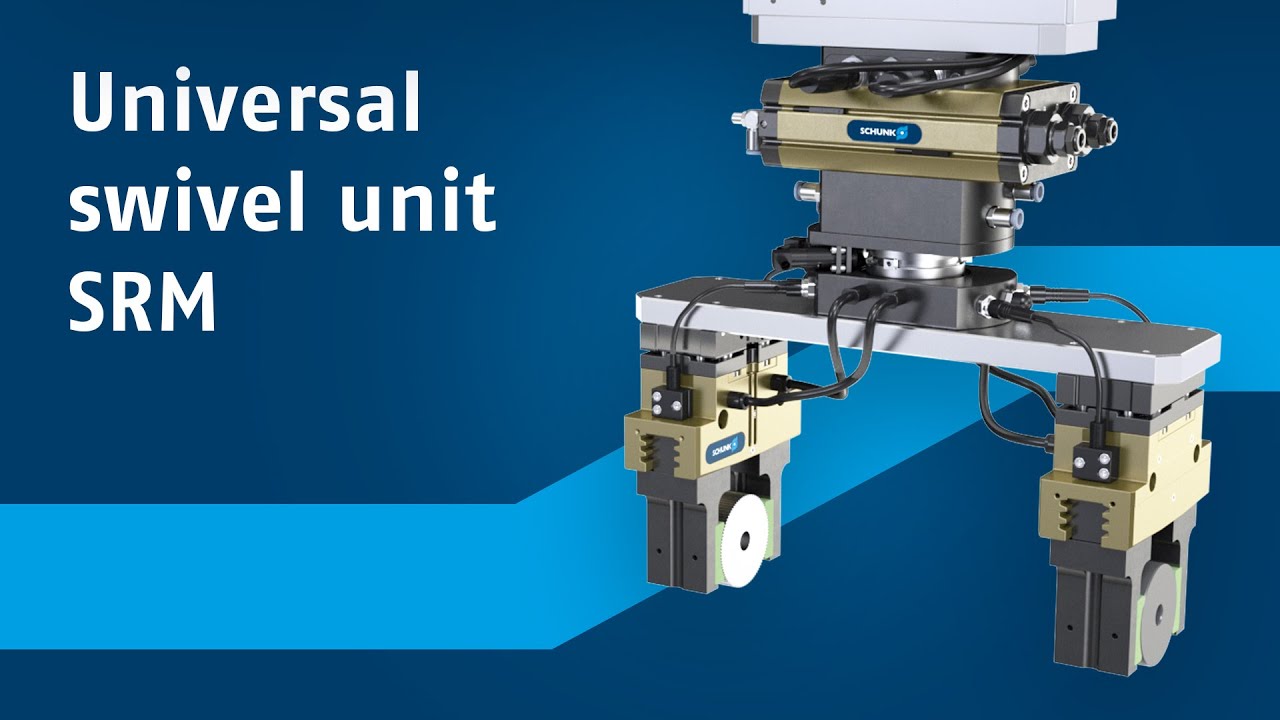

SRM

Universal swivel unit

Universally usable unit for pneumatic swivel and turning movements

气动通用旋转单元在自动化生产中表现了卓越的性能和更高的经济性。专门开发的减振器可确保小空间内的优异性能。大中心通孔支持多种介质连通选型,可按需设计高效的解决方案。

产品优势

- 坚固耐用

• 稳固、大接触面法兰接口

• 由于小齿轮的预装轴承没有间隙,可承受较大的载荷和扭矩

• 高品质 FwieKM 密封件,弹性佳,使用寿命长 - 性能优越

• 高扭矩和高转动惯量的优势组合,旋转时间短

• 高功率密度,紧凑设计 - 调试简便

• 已预设阻尼器行程,客户仅可调整空气节流阀

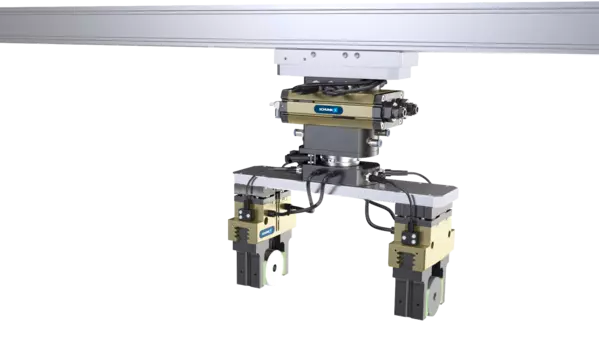

• 大中心孔,标准气管和电缆可轻松通过

• 使用电路通道时,传感器电缆可直接插入。插头连接器通过颜色标识,简化信号分配

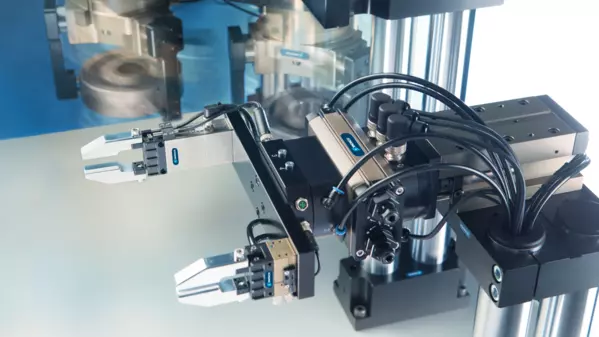

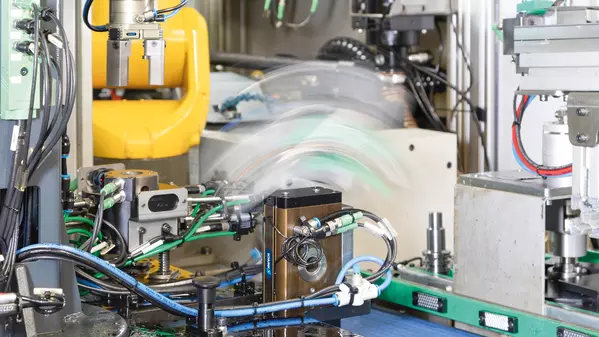

应用领域

产品动画演示

产品动画详细介绍了通用旋转单元 SRM。除产品的性能描述外,还包含关于调试、规格及变型的介绍。