RCG

Funktion

Sectional diagram

Sectional diagram

The battery cell is held by a strong permanent magnet inside the round cell gripper. The permanent magnet is activated pneumatically by the change of its position in the piston chamber. The permanent magnet is moved towards or away from the workpiece via a pneumatic piston, thereby "activating" or "deactivating" it.

- 1

-

Pneumatic drive

with C-slot for piston stroke monitoring system - 2

-

Electrically decoupled contact surface

to protect the charged battery cell that is in flat contact - 3

-

Centerings

The centerings in versions -2 and -4 are used to compensate for placement tolerances when picking up the battery cells.

Workpiece detection

Piston stroke monitoring

Gripping force maintenance

Pneumatic connections for the power supply

Round cells 46x

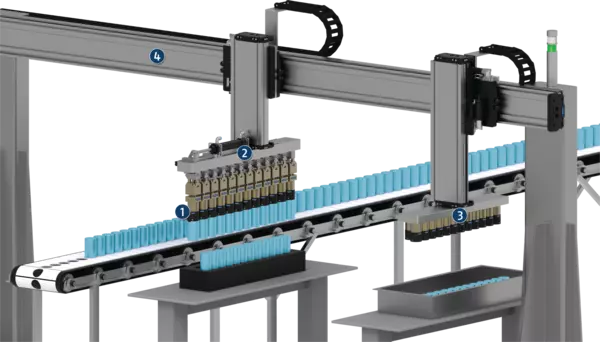

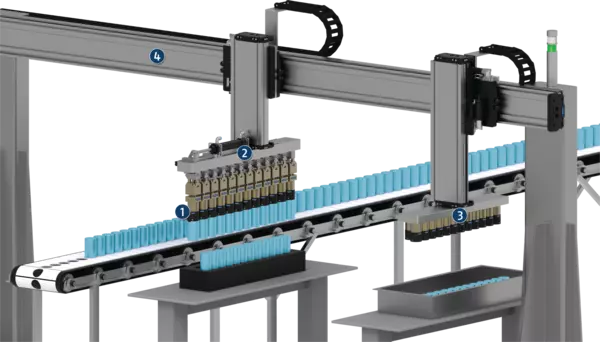

Multiple gripper unit

End-of-line

电芯分隔单元

Workpiece detection

Workpiece detection via component presence monitoring with an inductive proximity switch.

Piston stroke monitoring

The status detection "magnet activated" or "magnet deactivated" is ensured via the piston stroke monitoring system with solenoid switches.

Gripping force maintenance

Gripping force maintenance in the event of a compressed air failure is provided by the principle of the permanent magnet. The magnetic holding force holds the battery cell securely, avoiding workpiece loss, and ensures maximum process reliability.

Pneumatic connections for the power supply

Optional main air connections on the side or direct bottom-sided air connections for space-saving integration of several individual grippers in one gripping system.

Round cells 46x

The magnetic gripper RCG 46 can securely handle all common formats of Ø 46 mm round cells.

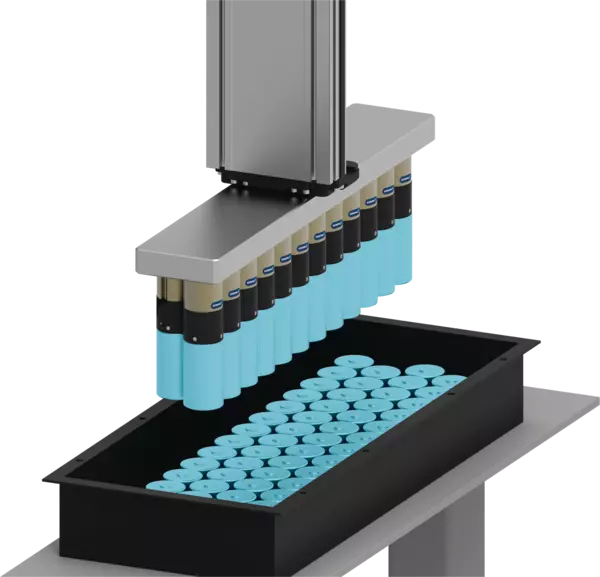

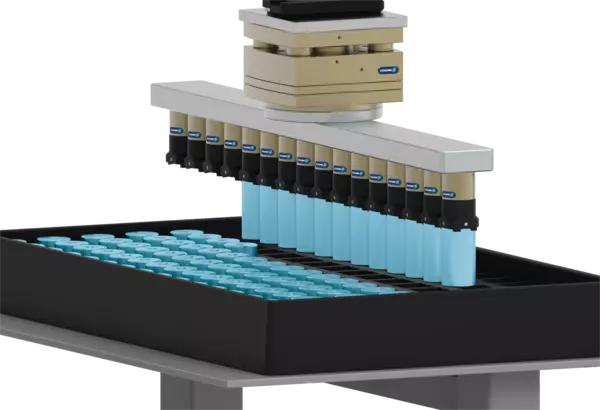

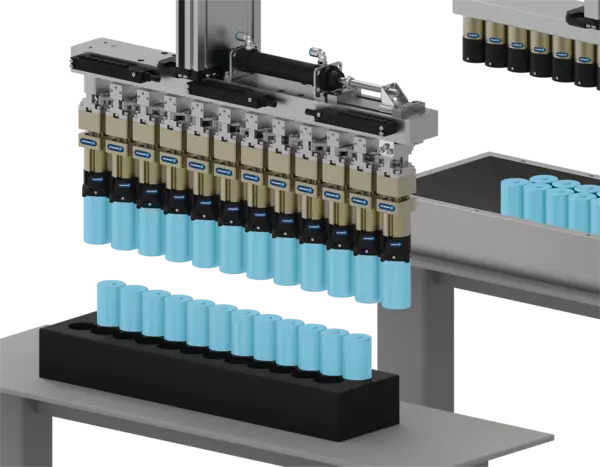

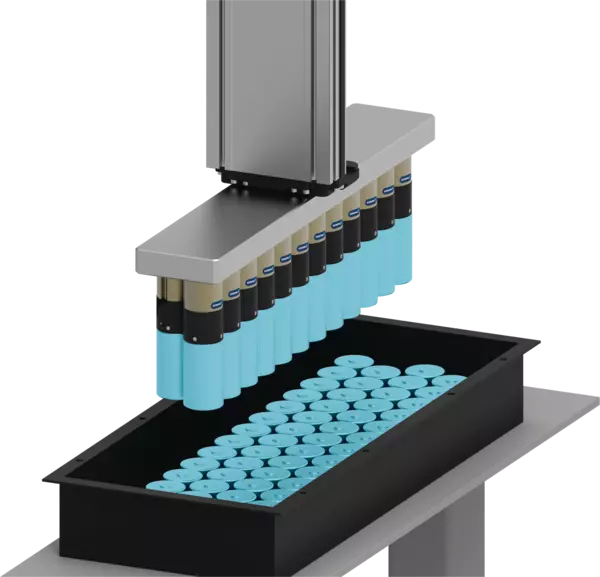

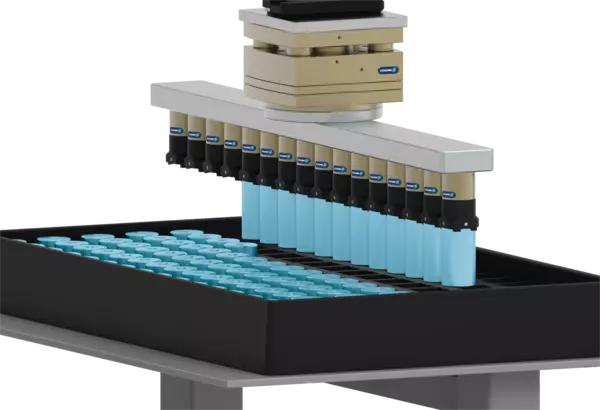

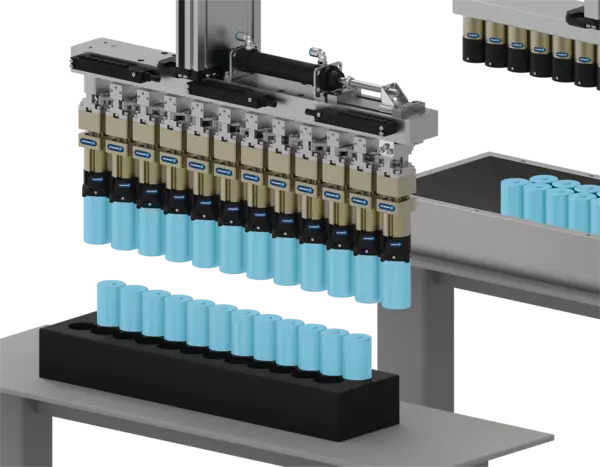

Multiple gripper unit

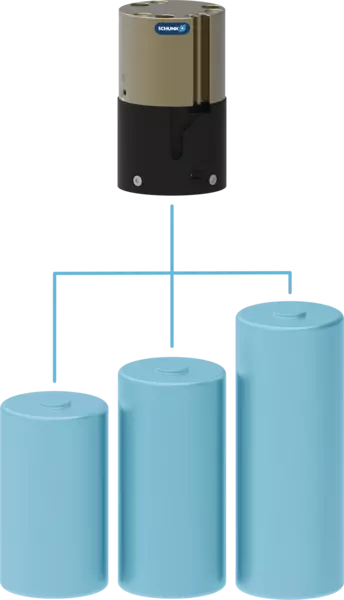

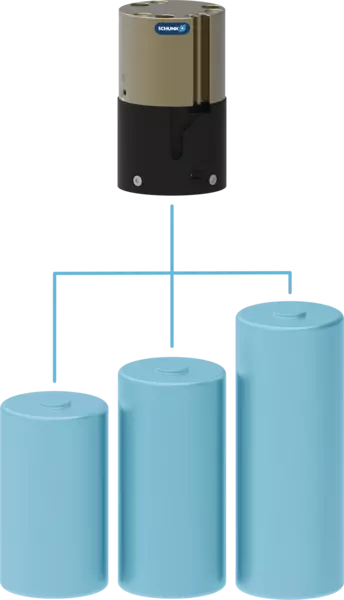

The round cell gripper RCG can be set up as an individual multiple gripper unit in order to realize the specific cell spacing depending on the application. Whether one, two, ... or even several hundred individual grippers.

End-of-line

The possibility of individual control for each round cell gripper RCG means that individual battery cells can be ejected in the process sequence, e.g. in the end-of-line testing process.

电芯分隔单元

电芯分隔单元还具备在取放过程中更改多个电芯间距离的功能。可根据应用对要抓取的电芯数量和电芯间距进行单独调整。

应用示例

应用示例

RCG 46 圆柱电芯机械手能够在无干扰轮廓的情况下搬运直径为 Ø 46 mm 的电芯。与特定于应用的抓取装置相结合,可实现电池模块和电池组中的所有工艺步骤。

- 1

-

圆柱电芯机械手 RCG

- 2

-

特定于应用的抓取装置,包括公差补偿单元和电芯分隔单元

- 3

-

特定于应用的抓取装置

- 4

-

线性直轴 SLD