SRM 20-H-180-90-SF

ID 1414892

- Angle of rotation: 180 °

- End position adjustability: 90 °

- End position damping: hydr. damper

- Torque: 3.6 Nm

Détails techniques

| エンド位置ダンパー | 油圧ダンパー |

|---|---|

| 回転角度 [°] | 180 |

| トルク [Nm] | 3.6 |

| 中間位置の数 | なし |

| IP 保護等級 | 65 |

| 重量 [kg] | 1.61 |

| 流体消費量 (2x 定格角度) [cm³] | 45.0 |

| 呼び作動圧力 [bar] | 6.0 |

| 最低作動圧力 [bar] | 4.0 |

| 最大作動圧 [bar] | 6.5 |

| 接続ホース径 | 6 x 3.9 x 1.05 |

| 最低周囲温度 [°C] | 5.0 |

| 最高周囲温度 [°C] | 60.0 |

| クリーンルーム等級 ISO 14644-1:2015 | 5 |

| 繰り返し精度 [°] | 0.05 |

| センターボア径 [mm] | 14.1 |

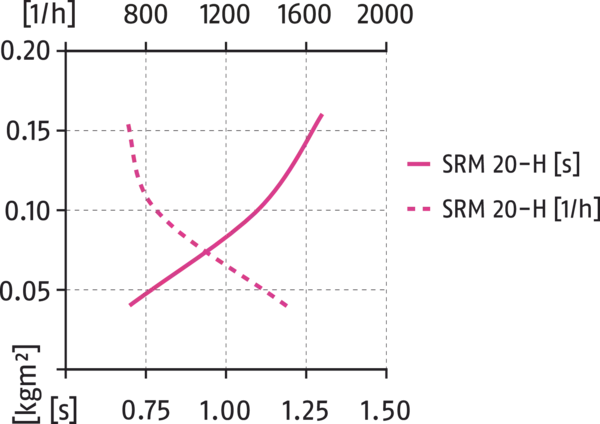

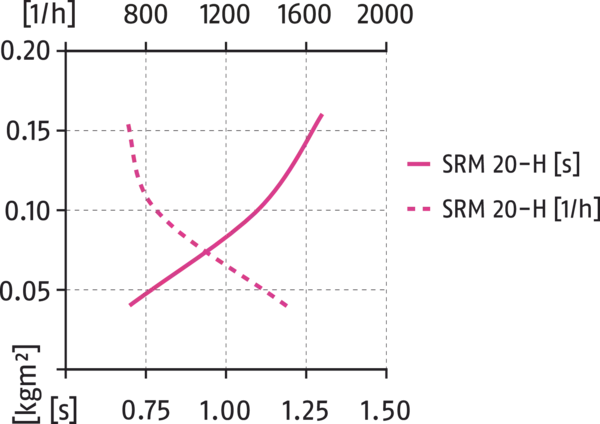

| 最大許容質量慣性モーメント [kgm²] | 0.16 |

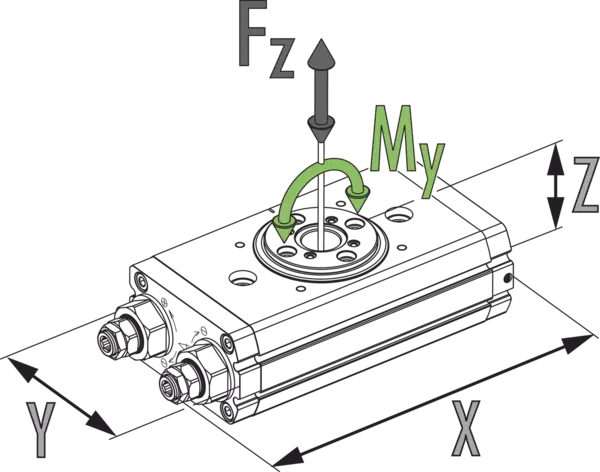

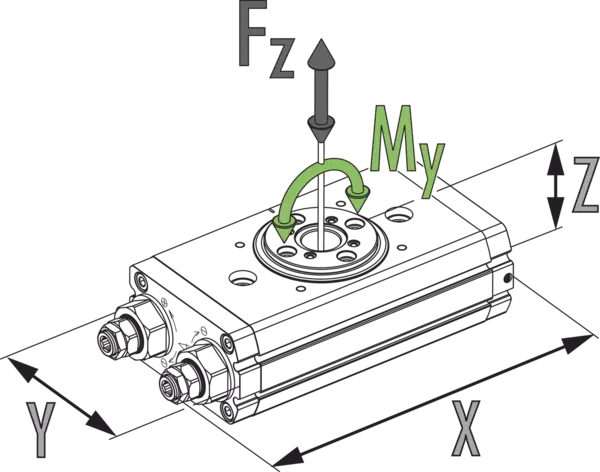

| トルク My 最大 [Nm] | 46.0 |

| 最大軸方向力 Fz (最大) [N] | 2000.0 |

| 誘導型近接スイッチのオプション | あり |

| 誘導センサーバージョン、固定式 | あり |

寸法と最大荷重

最大許容イナーシャ J*

寸法と最大荷重

示された負荷トルクと荷重は固定値であり、ベースユニットに対して有効であり、同時に発生することがあります。確実に衝撃や縦揺れなく旋回するよう、絞りを行う必要があります。スロットリングを行わない場合耐用年数が短くなります。

最大許容イナーシャ J*

- Axe X:

- 旋回時間

- Axe Y:

- 質量慣性モーメント

- Axe X supérieur:

- サイクル数 / 時

General notes about the series

Repeat accuracy

is defined as a distribution of the end position for 100 consecutive cycles.

Pinion position

is always shown in the left end position. The pinion rotates from here to the right in clockwise direction. The arrow makes the direction of rotation clear.

Pinion screw connection diagram

When setting a swivel angle smaller than 90°, the left end stop must be completely turned in. This means that the left end position has a screw connection diagram on the pinion which is clockwise turned by 90° compared to the main view, which shows a swivel angle of 180°.

Customized angle of rotation

More swivel angles are available on request.

Torque in the end positions

Please note that the final angular degrees (approx. 2°) before the end position can only be approached using the force of a single drive piston. For this reason, double actuated modules only have about half the rated torque available in this area.

Travel to the pneumatic middle position

is carried out using only half of the nominal torque.

Swiveling time

is the rotation time of pinion/flange around the nominal rotation angle. Valve switching times, hose filling times, or PLC reaction times are not included and are to be considered when cycle times are calculated.

Standard conditions

The technical data shown refers to an environment of 20 °C and atmospheric pressure.

Housing material

Aluminum (extruded profile)

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Operating principle

Double piston rack and pinion principle

Scope of delivery

Swivel unit in the ordered variant, accessory kit (centering sleeves, O-rings for direction connection/detailed contents see operating manual) and safety information. Product-specific instructions can be downloaded at schunk.com/downloads-manuals.

Warranty

24 months

Service life characteristics

on request