ERT 12-40-N-N-H-N

ID 1436904

Universal rotary unit ERT, Size: 12, electrical, without feed-through, Angle of rotation: > 360 °, Middle position: freely programmable

- Torque: 1.52 Nm

- Nominal current: 1.04 A

- Power supply: 560 V

Technical details

| Nominal torque [Nm] | 1.52 |

|---|---|

| Peak torque [Nm] | 4.17 |

| Max. rotational speed [1/min] | 600.0 |

| Max. permissible mass moment of inertia [kgm²] | 0.07 |

| Repeat accuracy [°] | 0.01 |

| Axial run-out [mm] | 0.02 |

| Run-out accuracy [mm] | 0.02 |

| Weight [kg] | 2.4 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 40.0 |

| IP protection class | 40 |

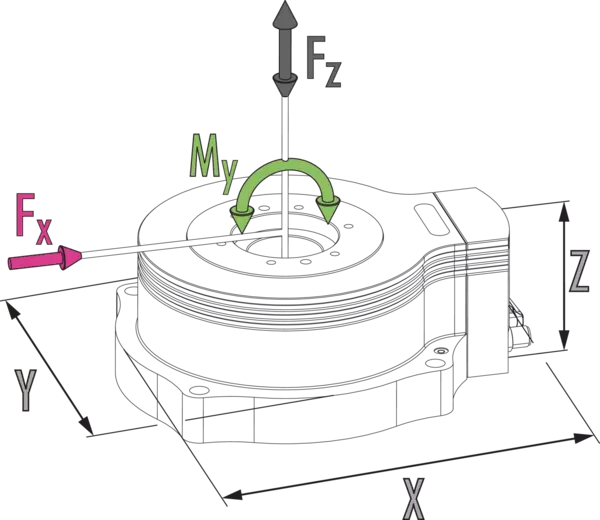

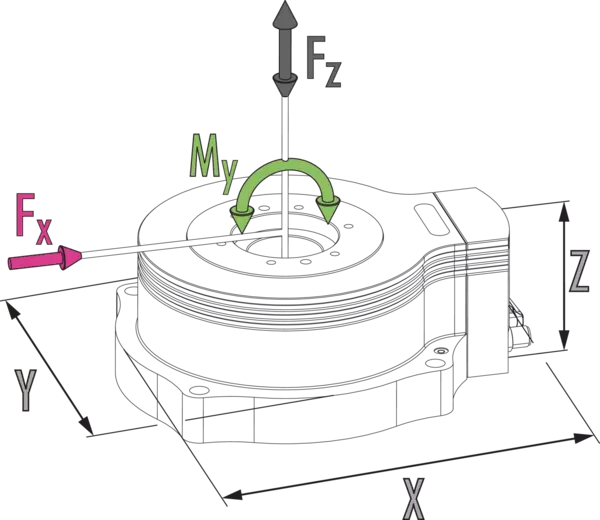

| Force Fx max. [N] | 700.0 |

| Force Fz max. [N] | 700.0 |

| Length X [mm] | 181.0 |

| Width Y [mm] | 135.0 |

| Height Z [mm] | 64.0 |

| Moment My max. [Nm] | 24.0 |

| Intermediate circuit voltage [V] | 560.0 |

| Nominal current [A] | 1.04 |

| Max. current [A] | 3.27 |

| Encoder system | Encoder (absolute) |

| Output signal | HIPERFACE® |

| SIL certification | not certified |

The peak torques serve as short-term drive reserves when accelerating and delaying.

尺寸和最大载荷

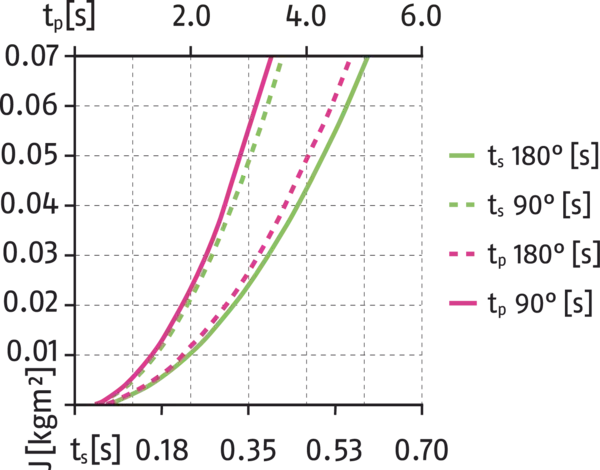

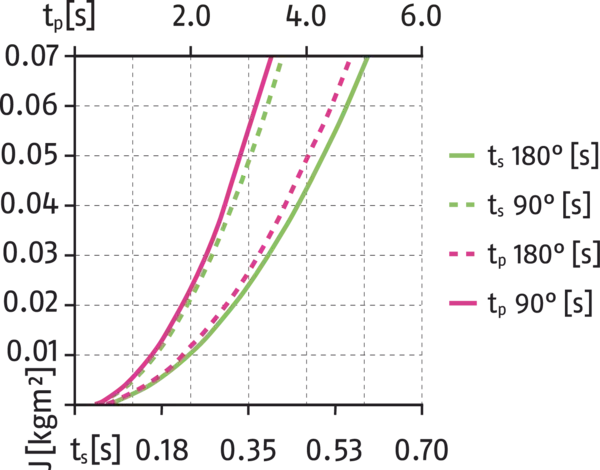

Swivel time diagram

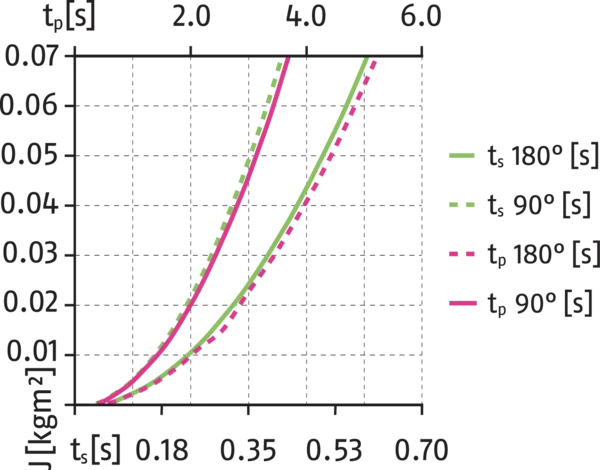

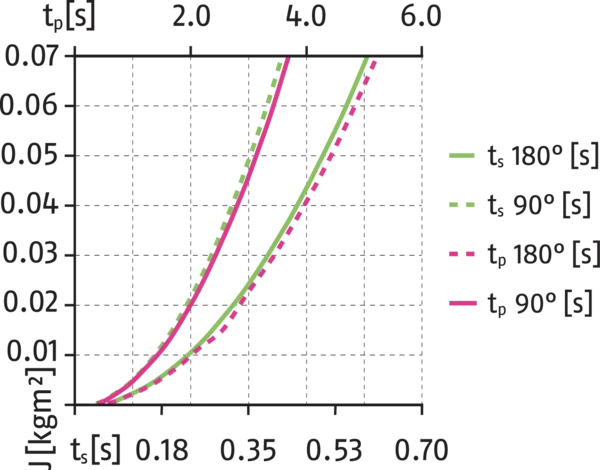

Swivel time diagram IP54

尺寸和最大载荷

此处所示力和力矩均为各荷载的最大值。如果同时施加多个力和/或力矩,允许的最大个别值将更低。

Swivel time diagram

- X-axis:

- Swiveling time

- Y-axis:

- Mass moment of inertia

- X-axis top:

- Cycles per hour

Swivel and pause times apply for motions without restricted speeds at max. current. Reducing the max. current increases swivel periods and reduces rest periods. Higher mass moments of inertia are possible. Diagrams only apply for sufficiently rigid designs. Please contact us for assistance with the design of your application.

Swivel time diagram IP54

- X-axis:

- Swiveling time

- Y-axis:

- Mass moment of inertia

- X-axis top:

- Cycles per hour

Swivel and pause times apply for motions without restricted speeds at max. current. Reducing the max. current increases swivel periods and reduces rest periods. Higher mass moments of inertia are possible. Diagrams only apply for sufficiently rigid designs. Please contact us for assistance with the design of your application.

产品系列的常规说明

行程测量系统

电机反馈系统,用于绝对测量,单转型式,带 HIPERFACE®、HIPERFACE DSL® 和 DRIVE-CLiQ 接口

回转时间

回转时间仅为模块从静止位置运动至静止位置的时间。不包括由 PLC 或驱动控制器引起的延迟,并且在确定循环时间时考虑延迟。周期必须包括与负荷有关的不工作时间。

设计或控制算法

有必要验证选定装置的尺寸,否则将导致超载。如需帮助,请联系我们。

重复精度

重复精度定义为 100 个连续定位循环后目标位置分布。

环境条件

模块专门用于清洁到轻微污染的环境条件。请注意:如果模块用于恶劣环境条件下,则可能会缩短其使用寿命,而SCHUNK 不承担此类责任。

安全注意事项

注意:磁场区域!特别对于配备植入性医疗器械的人员,例如,起搏器和助听器等。

额定电流

额定电流可以永久激活。当电流在额定和最大值之间时,必须遵照对应产品说明文件内的注意事项。

外壳材料

铸铝,粉末涂层

传动装置

扭矩电机,三相

行程测量系统

非接触式磁测量系统,有绝对值式变型;带 HIPERFACE® 和 DRIVE-CliQ 接口。

传动控制器

关于 BOSCH(EcoDrive CS、IndraDrive 和 IndraDrive CS)和 Siemens (Sinamics S120) 驱动控制器的参数设置咨询。为其他驱动控制器提供电机数据表。应要求提供调试支持。

标配范围

附件包含有定心套筒,安全信息(可线上获取对应产品说明书)

保修期

24 个月

使用寿命特性

根据要求