The electronics industry is characterized by continuous technological progress. Precise handling and machining of sensitive electronic components requires highest quality standards and precision. With our long-term experience in gripping technology, automation technology, toolholding and workholding, and depaneling technology, we are your reliable partner for the production, handling and final assembly of electronics and electronic components in the most diverse of industries.

Please feel free to arrange a non-binding consultation.

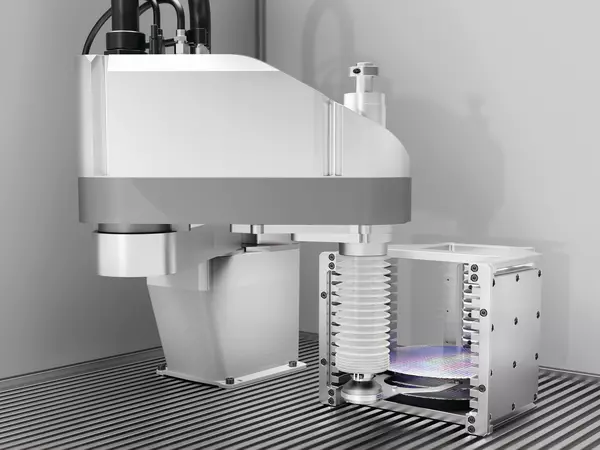

Wafer handling is a crucial step in electronics manufacturing, involving the loading and unloading of machines along the entire value chain, including the etching, exposure and polishing of wafers. This process requires maximum precision and cleanliness to ensure the quality and reliability of the electronic components produced.

SCHUNK offers specialized systems engineering expertise in the field of wafer handling to meet the specific requirements for ESD protection, cleanliness requirements, and the prevention of contamination. For example, the ADHESO technology enables precise wafer handling without the need for an external energy supply.

In electronics manufacturing, precision and efficiency are crucial in order to meet the growing requirements of the industry. Electronics manufacturing comprises various processes, including depaneling technology with axis control and end-of-line testing, which ensure the quality and performance of the electronic components produced.

Our expertise comprises various areas of electronics manufacturing, including inline depaneling, stand-alone machines, cells for placement and testing purposes. We offer customized solutions, which are adapted to the specific requirements and materials. Our solutions are also scalable and can therefore be adapted to changing quantities. We support you in checking feasibility and selecting the optimum solution for your electronics production.

The final assembly of electronic components in a wide range of industries such as automotive, data centers, aviation, measurement technology, consumer goods and telecommunications requires maximum precision and efficiency. This crucial step involves mounting the electronics in housings, establishing plug connections and closing the housings. It is particularly important to adhere to cycle times in order to maximize production capacity and the reliability of the components used.

Our gripper and automation technology enables precise and reliable gripping, swiveling, compensation and movement of electronics during the assembly process.

Our products are designed to minimize cycle times and increase productivity without compromising quality.

In CoLab, the SCHUNK Application Center, we work with you to test your planned application.

We support you with feasibility studies with your workpiece, process analyses and demonstrations of your process. This way you can minimize your risk and save time during commissioning.

Get in touch now with your SCHUNK consultant on site so we can discuss and develop your application.