Jaw quick-change chuck with patented seal

Mbb Metallbearbeitung Becker GmbH, Biedenkopf, Germany

The VERO-S NSE3 quick-change pallet system is impressive with its high pull-down force and the high dimensional stability of the module body. This allows for very high tilting moments and for shear forces to be absorbed by the modules.

This module can be expanded by a variety of different equipment. Their most striking feature is an optional, spring-actuated cone seal that automatically locks the module's change interface as soon as the clamping pin is lifted.

Positioning and clamping in one single operation – VERO-S gets to the heart of rationalization. This set-up time optimizer ensures higher machine running times, and a more rational production starting with batch size 1.

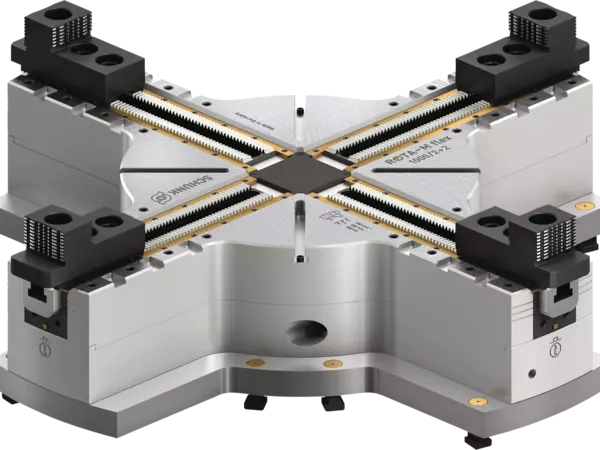

Completely sealed jaw quick-change chuck

The ROTA THW3 assures constant clamping forces, minimal maintenance costs and high energy efficiency – all packed into a power lathe chuck with jaw quick-change system. A patented sealing system located on the thrust jaws as well as on the release mechanism prevents grease from being flushed out and the gradual loss of clamping force. In addition, the seal prevents fine chips or dirt from penetrating into the chuck body.

If you want to manufacture turned parts more efficiently, low-maintenance and fail-safe precision clamping devices are required that can be quickly and easily converted and, if necessary, can be automatically loaded. The SCHUNK ROTA THW3 jaw quick-change chuck with its patented sealing of the chuck mechanism has been designed with this in mind.

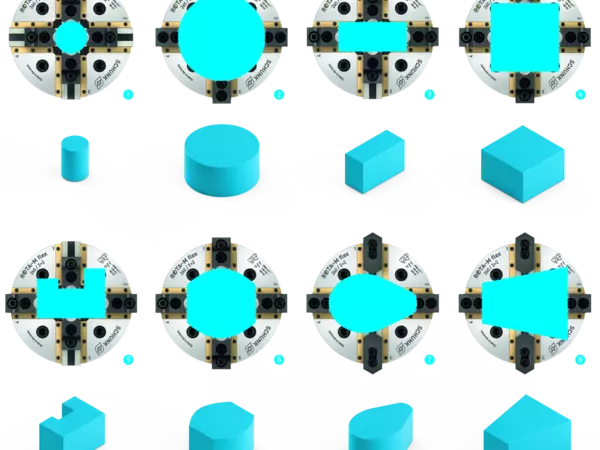

Flexible 4-jaw manual lathe chuck

With the ROTA-M flex 2+2, SCHUNK is combining the advantages and functions of 2, 3, and 4-jaw chucks on lathes and of vises on mill/turn machines. With the manual lathe chuck, it is possible to clamp round, cubic and geometrically bulky workpieces. A special seal prevents chips and coolant from penetrating into the chuck.