BSWS-R-PGZN-plus

Automatic jaw quick-change system

The automatic jaw quick-change system BSWS-R allows top jaws to be exchanged on the gripper automatically and rapidly. This increases the flexibility of the gripper with simultaneous unattended machine availability. The BSWS-R enables cost-efficient automatic change of workpiece-specific gripper fingers compared to changing the entire gripper.

Quick. Flexible. Cost-efficient.

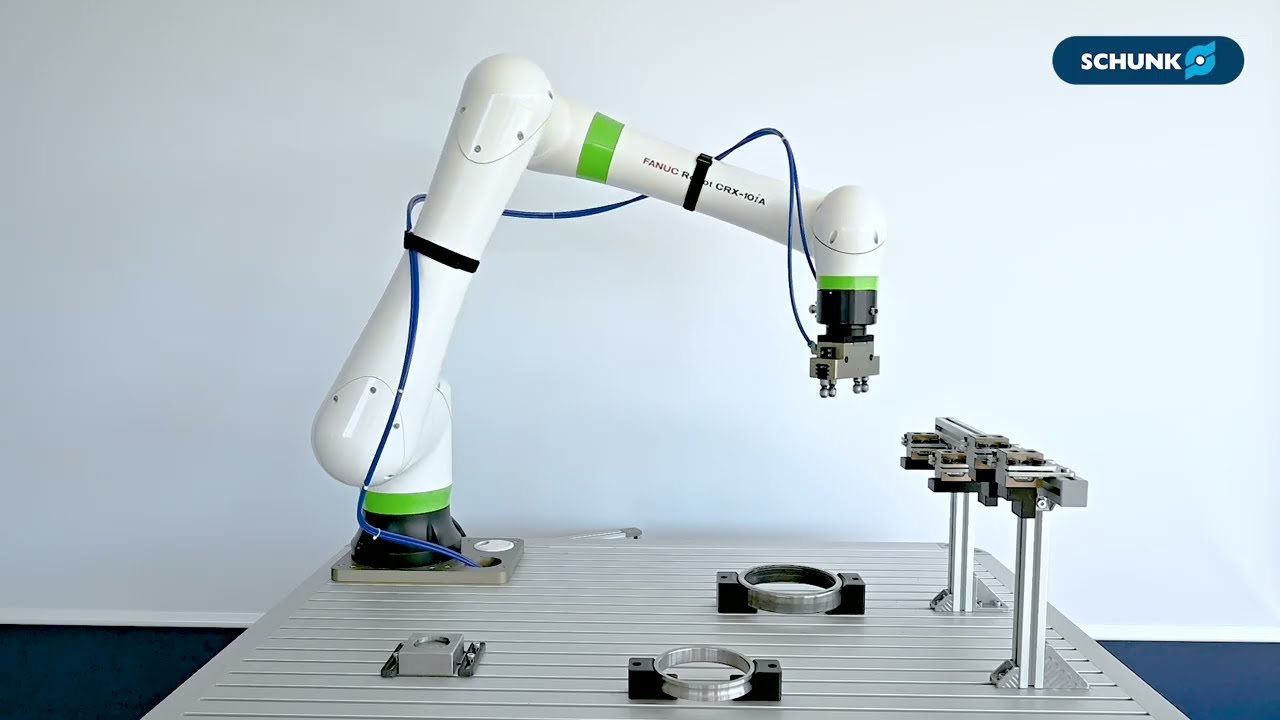

Automatic jaw quick-change system BSWS-R

Quick and simple changing, realized solely by the movement of the robot.

The automatic jaw quick-change system BSWS-R enables the quick and fully automatic changing of the gripper fingers. The change process is carried out exclusively by the movement of the robot. When the base is retracted into the storage station, the locking bolt is actuated and unlocks the mechanism As a result, a robot or an axis gantry can easily move upwards out of the jaw quick-change system while the base remains in the deposit station.

Take advantage of the benefits

- Maximum flexibility: with the BSWS family, a single gripper can be used universally in various applications.

- Saving time when converting applications: different workpieces can be handled by changing the gripper fingers.

- PGN-plus-P fingerprint enables universal use and retrofitting in a wide range of gripper series.

- Suitable for operation on cobots: deposit station prevents overloading of the robot through elastic mounting.

- Simple finger design: screwing through the gripper finger is no longer necessary, all that is required is that you insert a thread into the finger.

- Process reliability through monitoring the presence of the gripper finger in the deposit station by means of inductive proximity switches.

- No confusion of the gripper jaws possible: via finger coding using an RFID data carrier.