The automotive industry is facing a major upheaval – transitioning from the traditional combustion engine to E-Mobility. SCHUNK has a key role to play in this change and presents advanced concepts for the transition to battery technologies and electric drive systems. With innovative handling technologies for hairpin stators, shafts and rotors as well as advanced methods for final assembly, SCHUNK makes a significant contribution to the full automation of the electric drive. These strategies enable a smooth transition to E-Mobility and actively promote the dynamics of innovation.

Contact us for a non-binding consultancy appointment at e-mobility@de.schunk.com or +49-7133-103-3014.

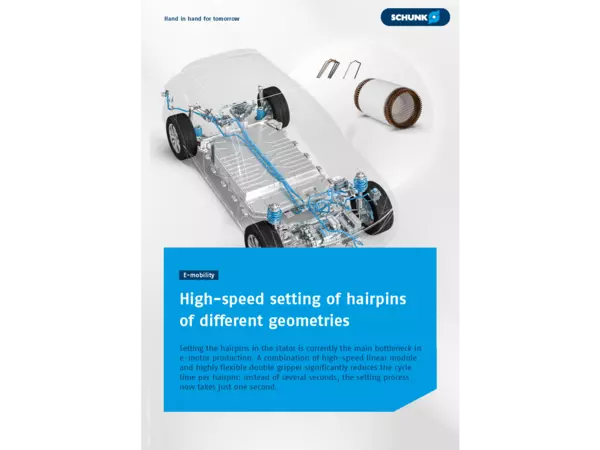

The pre-fitting of the hairpin is currently the main bottleneck impacting e-motor production. An innovative combination of a high-speed linear axis and a flexible double gripper reduces the cycle time per hairpin and thus increases output. Experience increased productivity with consistent precision.

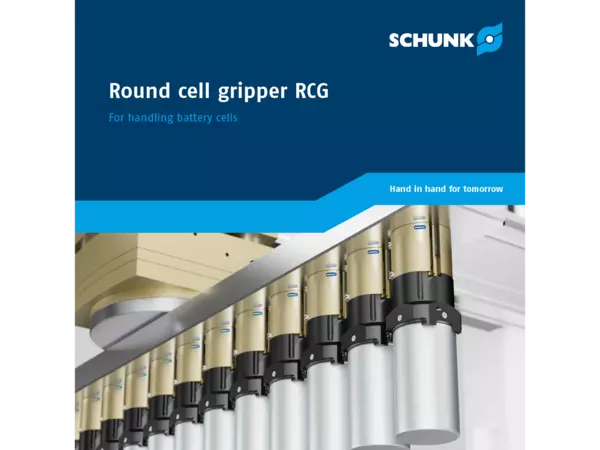

The RCG round cell gripper has a pneumatically controlled magnetic system with which battery cells can be picked up and placed. The RCG is typically used in multiple gripping units, for example in a row arrangement or for gripping a complete cell cluster. Compact external dimensions of the single gripper enable maximum packing density.

Tell us more about the application you want to automate. Our application experts will work with you to find the right solution. Contact us for a no-obligation consultation at e-mobility@de.schunk.com or +49-7133-103-3014.