The automotive industry has been a key industry for many years if it comes to implement new, economic and fully automated production lines for manufacturing vendor parts for the automotive industry.

Modern series production in the automotive and supplier industry requires maximum flexibility in adapting production processes. Fast availability, precision, quality, and process reliability are the deciding factors for success.

SCHUNK's decades of experience in the equipping of production systems within the automotive sector means we can offer the highest possible process reliability and maximum performance for our customers.

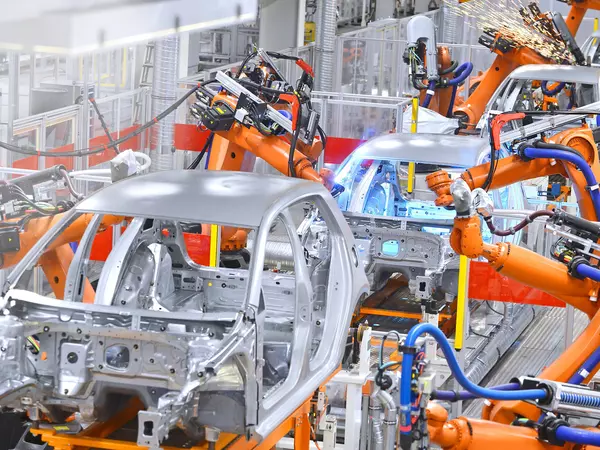

Body construction is a crucial phase in automobile production in which the outer structure of a vehicle is formed and assembled. The precision and efficiency of body construction have a direct influence on the safety, reliability and appearance of a vehicle.

Our large product portfolio allows us to support all processes in the area of body construction, such as the welding of seams, individual parts handling, screwing, deburring and grinding.

Our magnetic gripper, for example, is suitable for the precise handling of car body parts.

The application example demonstrates the framing process. This involves assembling the large individual components of the vehicle body. Our clamping technology supports the positioning of the side panels and guarantees a defined gap dimension.

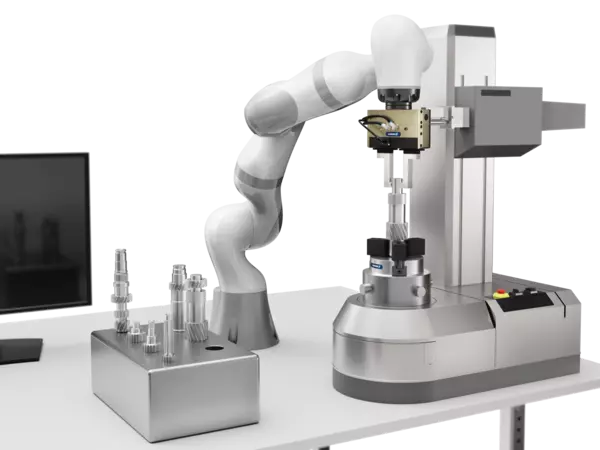

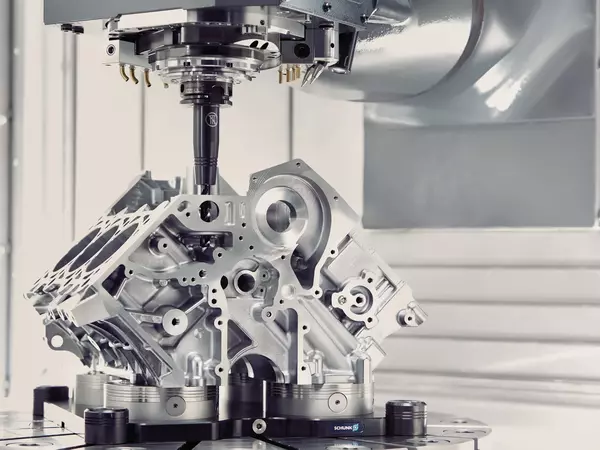

The drive train of a vehicle lies at the heart of its performance and mobility. It comprises the interaction of various components such as the motor, transmission, drive shafts and differential, which control the transmission and distribution of power. The requirements for drive trains are diverse and range from efficiency and reliability to meeting new challenges in the field of electromobility.

Our support covers all stages of the production chain - from raw part to finished part. SCHUNK offers components and innovative clamping technology for the key processes clamping, gripping, changing, moving, machining and assembly. We fulfill the most demanding of precision requirements.

In the application example, different gear shafts are positioned and clamped in a measuring application to enable high-precision measurements.

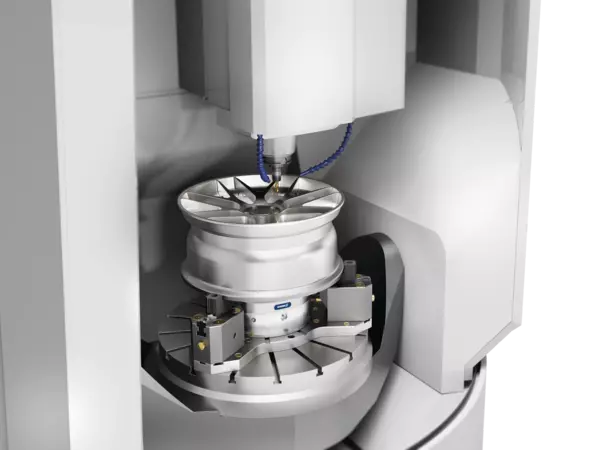

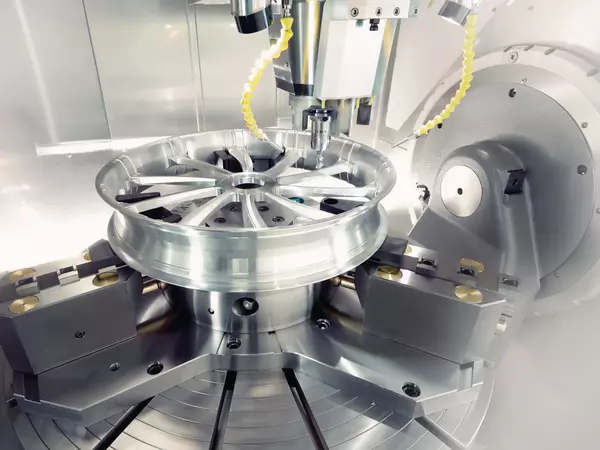

The chassis of a vehicle is of crucial importance for its driving dynamics, safety and ride comfort. It comprises a complex combination of components, such as suspension systems, shock absorbers, axles and wheels, which work together harmoniously to ensure optimum road holding and driving stability.

We support you in all these different manufacturing processes. Here we draw on a rich wealth of experience, professional consultation, and sound application expertise.

We offer optimum clamping devices for the "rim clamping and machining" application, tailored to the requirements of modern machine concepts.

Nowadays, electronic systems and control units are indispensable components that not only increase safety and comfort, but also improve the efficiency and performance of vehicles. The production, handling and assembly of electronic components, whether in the areas of safety systems, infotainment or drive electronics, requires the highest levels of precision and reliability.

Our expertise covers a wide range of areas in the field of electronics. Find out everything you need to know about wafer handling, electronics production and electronics final assembly at schunk.com/electronics .

In the CoLab, the SCHUNK Application Center, we work with you to test your planned application.

We support you with feasibility studies with your workpiece, process analyses and demonstrations of your process. This way you can minimize your risk and save time during commissioning.

Get in touch now with your SCHUNK consultant on site so we can discuss and develop your application.