Automation has become a strategic necessity for many manufacturing companies. The pressure comes from multiple directions: The ongoing shortage of skilled labor means fewer qualified professionals are available for repetitive or physically demanding tasks. At the same time, wage costs continue to rise as companies compete globally with significantly lower-cost production sites. Those who want to succeed today must become more efficient, flexible, and productive.

On top of this, demographic change is an increasing concern: in the coming years, many long-serving employees will retire, taking valuable experiential knowledge with them. Automation can not only provide relief but also help establish sustainable and stable processes. It offers the opportunity to reduce monotonous tasks, replace ergonomically strenuous activities, and ensure consistent quality and output.

Yet despite these clear advantages, many companies still hesitate to embrace automation. Their concerns? Too complex, too expensive, or seemingly "impossible". In practice, however, the right steps, clear goals, and an open mindset make automation easier to implement than many might think.

The following Dos and Don’ts offer practical guidance to help you get started with automation—insightful, actionable, and grounded in real-world experience.

Before diving into automation, take a moment to envision the near future of your production. Are you looking to automate just a few particularly time-consuming processes, or are you aiming for a comprehensive solution in the long run? This decision will impact not only the project’s complexity and cost, but also its technical design. Automating too early and too extensively without considering potential future product expansions - can lead to investments that need to be revised later. Equally important is clearly communicating this vision to external partners. Only when a service provider understands your long-term goals can they develop appropriate and scalable solutions.

Automation should never be viewed in isolation. It’s essential to also consider upstream and downstream processes. How are components delivered to the machine? What happens after the primary operation — whether it’s assembly, packaging, or something else? A practical example: if components are delivered in trays with specific formats, the automation solution should be designed to accomodate these conditions — ideally without the need for manual intervention. Those who pay close attention early on will save themselves later surprises and costs.

Decisions about new automation solutions are often made without employee involvement – despite the fact that this is where valuable knowledge resides. Those who work on the production floor every day know the smallest details and nuances of the processes. Involving them seriously not only shows respect but also improves the quality of the solution. Additionally, concerns about job security can be mitigated when employees understand that automation aims to free them from monotonous or physically strenuous tasks, allowing them to take on more pleasant and engaging roles.

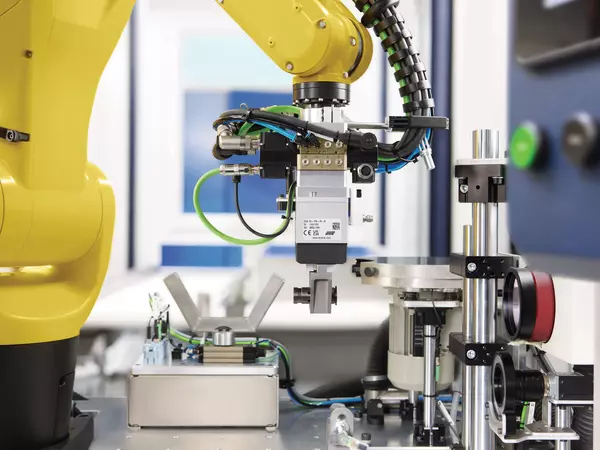

While costs are undeniably important, other factors – such as ergonomics, workplace safety, and sustainability - should also be considered when evaluating automation projects. Automation can relive workers of repetitive, monotonous, or physically demanding tasks, making roles more attractive to potential new employees. In addition, automated processes ensure consistent product quality and significantly reduce scrap rates. For example, manual quality checks often detect defects or rework requirements too late - after a large number of defective parts have already been produced. Automated 100% inspections using cameras can prevent this by identifying and reporting issues with the very first defective part. Energy and resource consumption — especially in pneumatic applications — can also be significantly reduced by using precise machinery instead of manual processes. Automation therefore, often leads to healthier factories: more sustainable, resource-efficient, and ergonomic.

Not everything needs to be solved internally. For complex topics like safety assessments or comprehensive process evaluations, drawing on external expertise can be invaluable. SCHUNK’s “automation check,” for example, offers an in-depth external perspective and opens up new opportunities. Experts bring not only technical know-how but also experience from numerous similar projects, helping you avoid common mistakes and find proven, tailored solutions.

In smaller or medium-sized companies, automation is often handled by general or production management as a secondary responsibility. However, without a clearly designated owner, both expertise and availability tend to suffer. Ideally, there should be a dedicated point of contact within the company who serves as the interface between technical teams, service providers, and internal departments. If such a role does not yet exist, it can be developed through targeted training — such as an application workshop at SCHUNK, where participants learn the basics of automation and potential identify potential opportunities.

The temptation to automate multiple processes simultaneously can be strong. However, this often leads to overwhelm, budget overruns, or even technical issues. Successful projects usually start small, focusing on a clearly defined core process. From there, they can be expanded step by step.

Not everything that can be automated should be. Some processes are more efficient when done manually — whether because they occur infrequently, are too complex, or simply because humans can perform them better and more cost-effectively. For example, simple steps like applying adhesive dots may be best handled manually, especially if the area is difficult for a machine to access. Striking the right balance is key.

Sometimes, during SCHUNK’s automation check, it becomes clear that a planned automation step doesn’t make sense. This isn’t a failure – it is part of the process. It is important not to cling rigidly to an initial idea, but to remain open to alternative solutions — even if that means leaving a process manual.

Automation can sometimes seem simpler than it actually is. Factors such as part variety, batch sizes, cycle times, degrees of autonomy, or environmental conditions significantly impact feasibility and costs. A seemingly simple task — like picking from a bulk container — can pose major challenges. Similarly, very short cycle times (under 10 seconds) are technically feasible but often come with high costs. All these aspects should be carefully considered in advance - ideally with expert support. Harsh environments, for example, place different demands on machinery than clean ones and require tailored solutions. Whether the machine operates 24/7 (including unattended night shifts) or is always monitored by an experienced operator makes a significant difference. SCHUNK’s automation check offers a holistic review that ensures such factors are considered from the start.

Automation is a vital lever for addressing today’s challenges — from labor shortages and rising costs to demographic change. By taking a strategic approach, setting realistic goals, and involving both employees and external expertise, you lay the foundation for future-proof processes. With a clear vision and pragmatic execution, embracing into automation becomes a genuine opportunity. Learn more