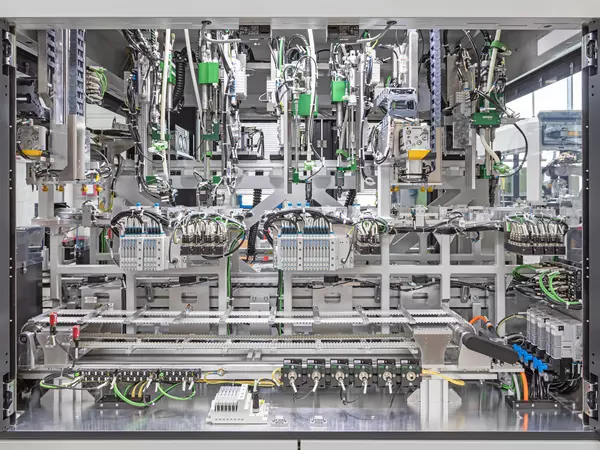

Baumann Automation develops customer-specific production platforms for robotics, assembly, handling and testing technology in the industrial park in the north of Amberg, in the Upper Palatinate – around 70 kilometers from the Czech border. The standardized automation cells offer flexibility, scalability and 100% customization. "We make sure that customer requirements and our solutions are a perfect match," assures Michael Klaus, Project Manager Assembly Solutions at Baumann. "Customers demand the best machines, that's what we aim for. And for this, we need the best components." SCHUNK products, for example grippers and changing systems, are installed in many areas of the Baumann systems. The North Bavarian special machine manufacturer recently had a particularly tricky task to solve: a screw assembly cell with remarkably compact dimensions that had to fit precisely into the customer's existing production line. "Five screwdriving stations plus two handling units had to be accommodated in an extremely limited space," explains project manager Klaus. "It was a matter of millimeters here. The lack of space was the dominant theme. We searched for a solution for a while, but after an intensive engineering phase together with SCHUNK, we finally found a top solution: the use of the SLD linear direct axis with five independently movable slides for the screwdriving units."

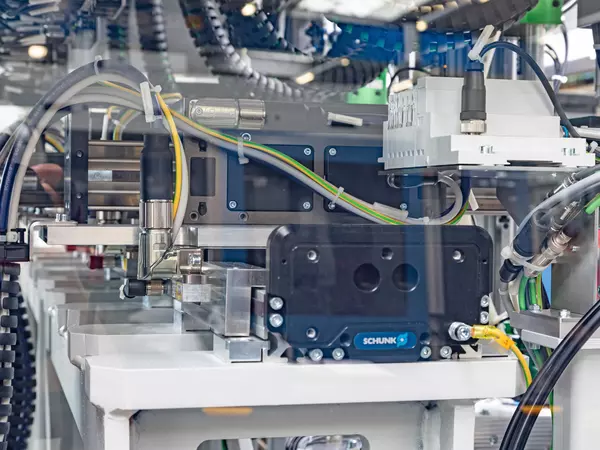

A 1.81-meter-long SLD linear direct axis on a steel beam extends horizontally across the entire width of the cell, from end to end. Five high-precision guided slides move on this axis, which can move independently of one another under application-specific control. An LDN universal linear module from SCHUNK is installed on each slide of this x-axis by means of an adapter plate - a linear axis with X-profile, linear direct motor and roller guide. Each of these LDN modules, which move in the y-direction, has a screwdriving spindle attached as an end effector, which carries out the screwdriving processes in the z-direction.

At the start of the screwdriving process, the workpiece - a pre-assembled pump assembly - reaches the screwdriving cell on the left-hand side via an infeed conveyor on a workpiece carrier. At the cell entrance point, a barcode label on the component, containing all the stored product data, is first scanned. The component lid is then automatically removed from a stationary, vertical handling module using a suction gripper and placed on the side of a secondary conveyor; this carries the lid parallel to the process until it is replaced. The lid-free housing is then cycled through four screwing stations. Various screws are fitted to the housing and a circuit board is attached. Finally, a second stationary vertical handling unit uses a suction gripper to pick up the parallel lid from the secondary conveyor and places it back onto the housing. The lid is finally screwed on at the fifth and final screwing station. Finally, the pump assembly is moved in from the cell on the front right-hand side. Integrated quality monitoring of the screwdriving process in the spindle ensures a flawless screw connection. In the event of a faulty screw connection, the NOK component would be automatically ejected. The production cell works fully automatically 24/7; manual intervention is only necessary in the event of faults. Baumann has designed the "ro|box" basic cell module to be easily accessible and simple to operate.

The five screwdriving stations move independently of one another on the SLD axis. This means that the various screwdriving processes can be precisely coordinated and all screwdriving processes are reliable. This forms the basis for ensuring that the pump, an important product in modern and environmentally friendly energy technology, is passed on to the next line station of the pump manufacturer in perfect quality. "The robustness and precision of the SLD guarantees flawless screwdriving processes and ultimately ensures that rejects and waste are avoided," Michael Klaus points out.

In a specific application, this SLD linear direct axis carries around ten to twelve kilograms on each of the five slides including adapter plate, LDN linear axis and screw unit. The high load capacity is possible thanks to the heavy-duty profiled rail guide - this ensures precise processes. Each slide or linear motor has its own controller. The TTK 70S non-contact linear encoder measures the absolute position and speed with maximum precision. "Thanks to the integration of the motor and safety features, and the resulting compactness, we were able to solve our space problem with the SLD," summarizes project manager Klaus. Otherwise we would not have been able to fit the entire screwing process into two 1.60-meter cells."

The installed linear direct axis SLD 11, a configurable standard product from SCHUNK, was also an excellent choice for Baumann in terms of the price/performance ratio. Users benefit from its modular attachment, installation and combination options - for example, the SLD can be equipped with a brake and can be fitted with a cover strip. Depending on the customer application, the SLD can be equipped with several active motor slides and enables special axis solutions.

"We really implemented this challenging project hand in hand," confirms Michael Klaus. "This SCHUNK philosophy suits us very well here at Baumann. SCHUNK spared neither time nor effort in assisting us in finding what truly is the best solution. The result is unique and our customer is delighted. All in all: a perfect match!"