Automated machine loading

The electrically actuated universal gripper EGU can be used very flexibly for different applications in harsh ambient conditions due to its design and sealing concept.

To the EGU flyer

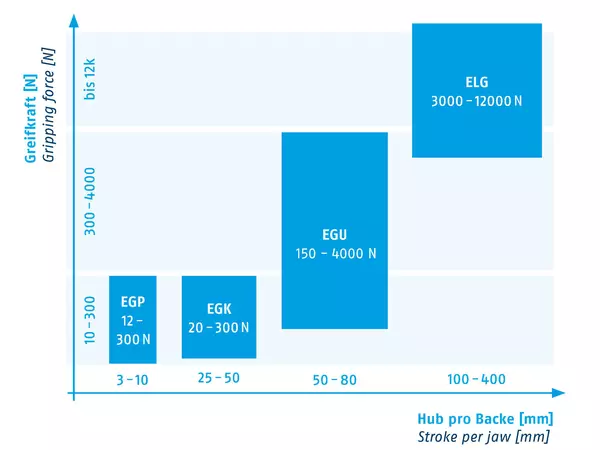

Our range of electric grippers currently comprises four product series that are optimally adapted for use in various application areas in terms of gripping force and stroke. This allows you to quickly find the right gripping solution for your application.

For the requirements of modern process flows, mechatronic gripper solutions offer many advantages.