EGL 90-CN

ID 1325754

Produits alternatifs :

- 죠당 스트로크: 42.5 mm

- 최소 파지력: 50 N

- 최대 파지력: 600 N

- 전원공급장치: 24 V DC

- 최대 주위 온도: 55 °C

Détails techniques

| 죠당 스트로크 [mm] | 42.5 |

|---|---|

| 최소 파지력 [N] | 50.0 |

| 최대 파지력 [N] | 600.0 |

| 권고 공작물 중량 [kg] | 3.0 |

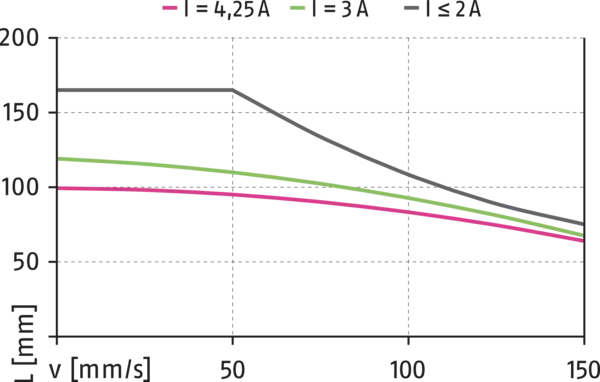

| 최대 허용 가능 핑거 길이 [mm] | 165.0 |

| 핑거당 최대 허용 무게 [kg] | 0.5 |

| 반복 정밀도 [mm] | 0.05 |

| 폐쇄 시간 [s] | 0.7 |

| 개방 시간 [s] | 0.7 |

| 최대 속도 [mm/s] | 150.0 |

| 최대 가속도 [mm/s²] | 2500.0 |

| 중량 [kg] | 1.8 |

| 최소 주위 온도 [°C] | 5.0 |

| 최대 주위 온도 [°C] | 55.0 |

| IP 보호등급 | 46 |

| 클린룸 클래스 ISO 14644-1:2015 | 4 |

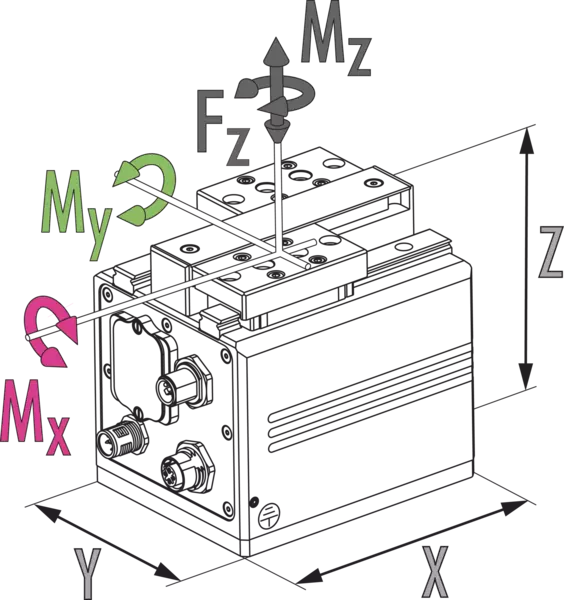

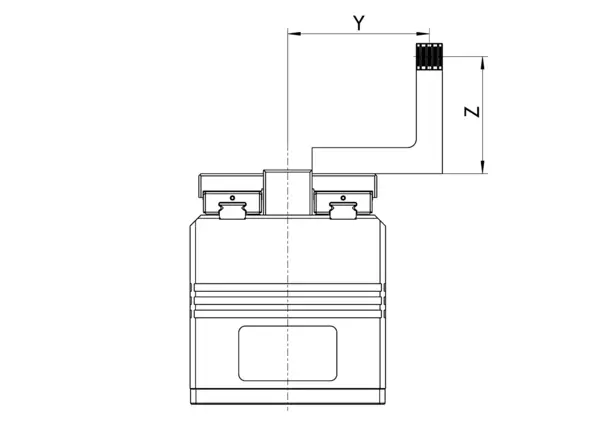

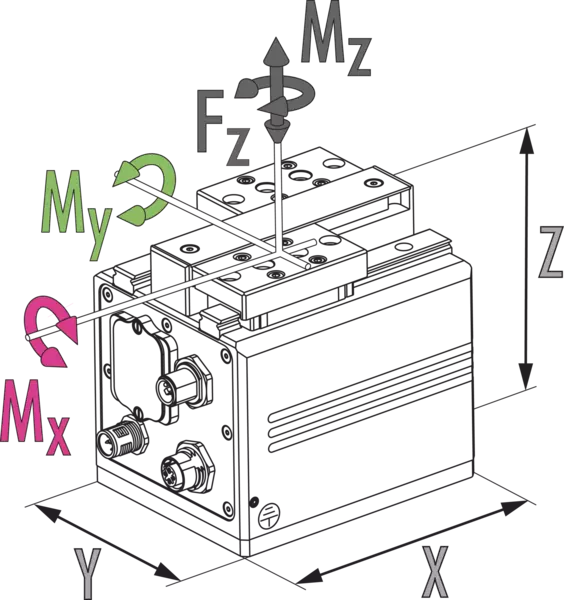

| 길이 X [mm] | 112.0 |

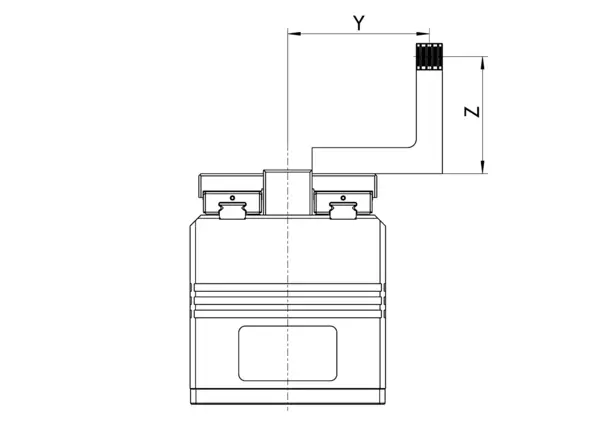

| 너비 Y [mm] | 90.0 |

| 높이 Z [mm] | 108.0 |

| 컨트롤러 전자 장치 | 통합형 |

| 정격 전압 | 24.0 |

| 통신 인터페이스 | CAN |

| 매개 변수화된 인터페이스 | USB |

| 최대 전력 [A] | 2.5 |

| 최대 전류 논리 [A] | 0.5 |

| 모멘트 Mx 최대 [Nm] | 20.0 |

| 모멘트 My 최대 [Nm] | 20.0 |

| 모멘트 Mz 최대 [Nm] | 20.0 |

| 최대 축 포스 Fz 최대 [N] | 400.0 |

| CAN 버전 | 예 |

치수 및 최대 로드

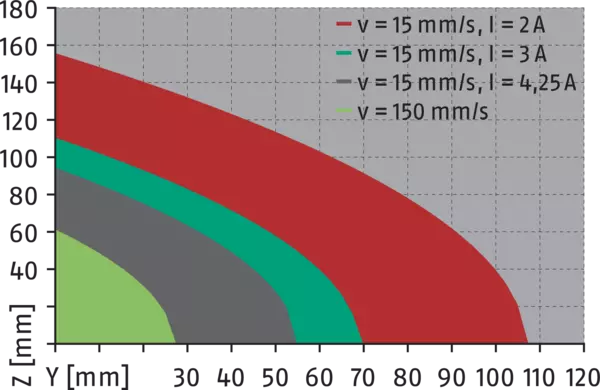

Maximum permitted finger projection

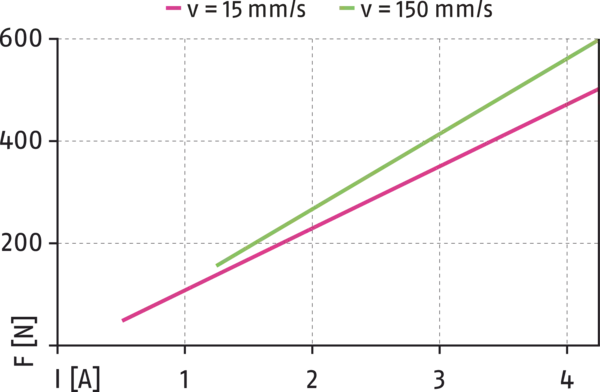

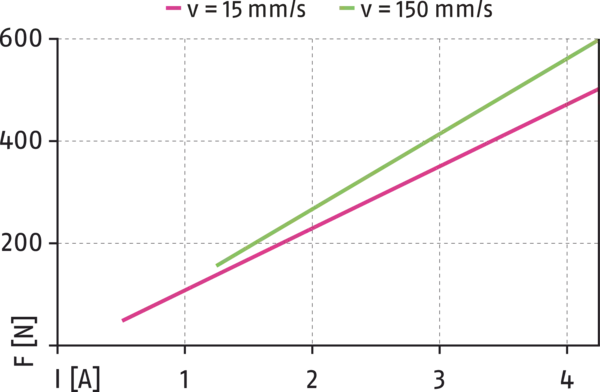

파지력

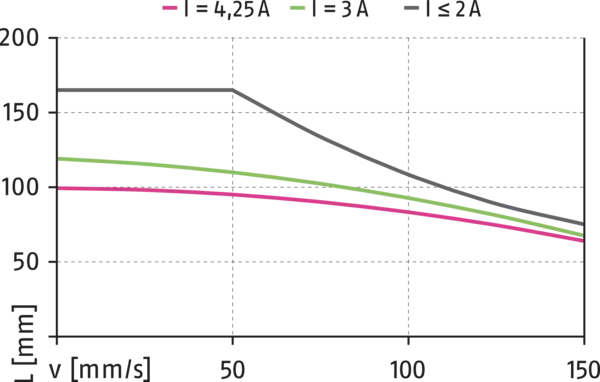

핑거 길이

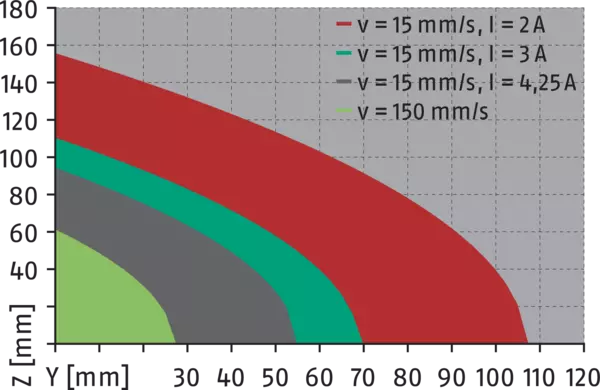

최대 허용 핑거 추정

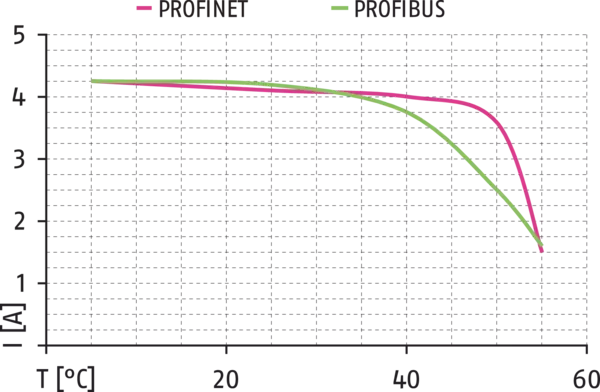

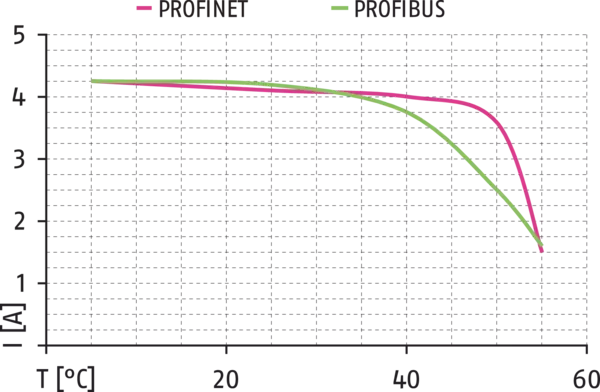

정격감소

치수 및 최대 로드

표시된 모멘트와 포스는 정적인 값이고 각 베이스 죠에 적용되며 동시에 나타날 수 있습니다. 부하가 파지력 자체에 의해서 생성되는 모멘트에 추가로 발생할 수 있습니다.

Maximum permitted finger projection

파지력

- Axe X:

- 모터 전류

- Axe Y:

- 파지력

핑거 길이

- Axe X:

- 죠 속도

- Axe Y:

- 핑거 길이

최대 허용 핑거 추정

- grey

- 허용 불가 범위

정격감소

스로틀 다이어그램은 주변 온도에 따라 허용 가능한 최대 모터 전류를 나타냅니다.

- Axe X:

- 주변 온도

- Axe Y:

- 모터 전류

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

Minimum closing and opening times are merely the movement times of the base jaws or fingers at max. speed, max. acceleration, without current limitation (maximum current), and observance of the maximum permissible mass per finger.

Nominal currents

can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Electrical brake

The built-in, electric holding break is used for fixing and holding the position of the gripper jaws in the event of a power failure. It cannot cover all of the security or gripping force maintenance functions.

Operating principle

Rack and pinion principle

Housing material

Aluminum alloy, coated

Base jaw material

42CrMo4+QT

Actuation

servo-electric, via brushless DC servomotor

Warranty

24 months

Scope of delivery

Gripper including safety information and accessory kit with centering sleeves for gripper and finger mounting. Product-specific instructions and software can be downloaded at schunk.com/downloads-manuals and schunk.com/downloads-software.