PRH 060-030-PB-65

Ident.-Nr. 306882

- Getriebeübersetzung: 30:1

- Drehmoment: 1.8 Nm

- Nennstrom: 3.7 A

- Spannungsversorgung: 24 V

- Schutzart IP: 65

Technische Details

| Spitzendrehmoment [Nm] | 4.5 |

|---|---|

| Nenndrehmoment [Nm] | 1.8 |

| Nenndrehzahl [1/min] | 117.0 |

| Max. Drehzahl [1/min] | 200.0 |

| Max. zul. Massenträgheitsmoment [kgm²] | 0.012 |

| Wiederholgenauigkeit [°] | 0.004 |

| Planlauf [mm] | 0.01 |

| Rundlauf [mm] | 0.01 |

| Übersetzung | 30:1 |

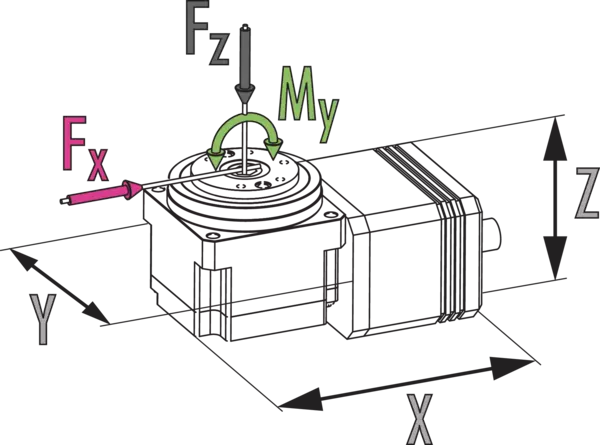

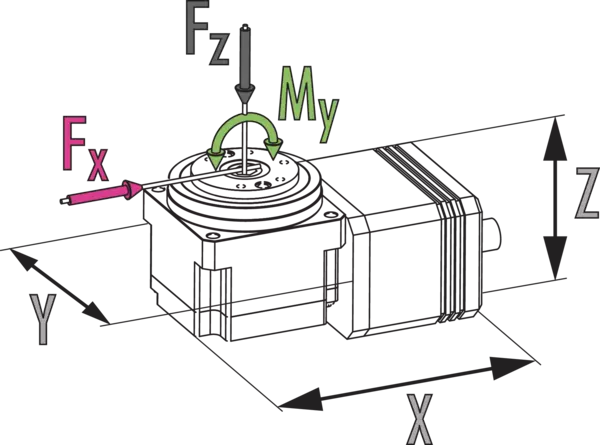

| Moment My max. [Nm] | 40.0 |

| Kraft Fx max. [N] | 300.0 |

| Kraft Fz max. [N] | 300.0 |

| Eigenmasse [kg] | 0.97 |

| Min. Umgebungstemperatur [°C] | 0.0 |

| Max. Umgebungstemperatur [°C] | 40.0 |

| Schutzart IP | 65 |

| Länge X [mm] | 127.5 |

| Breite Y [mm] | 67.0 |

| Höhe Z [mm] | 64.5 |

| Nennspannung [V] | 24.0 |

| Nennstrom [A] | 3.7 |

| Max. Strom [A] | 7.8 |

| Steuerelektronik | integriert |

| Spannungsversorgung [V] | 24.0 |

| Gebersystem | Encoder (inkrementell) |

| Schnittstelle | PROFIBUS, USB (Parametrisierung) |

| PROFIBUS-Schnittstelle [Mbit/s] | 12.0 |

| USB-Schnittstelle | Device |

| Anzahl digitaler Eingänge | 4.0 |

| Anzahl digitaler Ausgänge | 0.0 |

Dimensionen und max. Belastungen

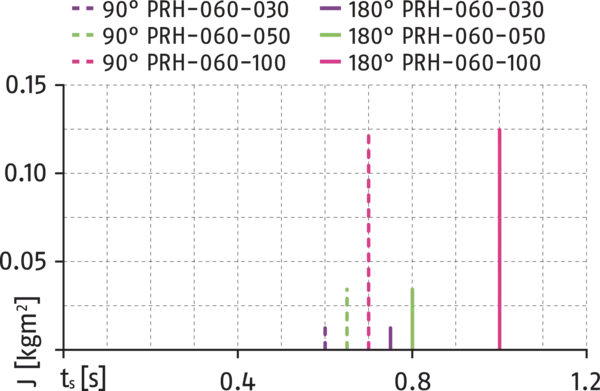

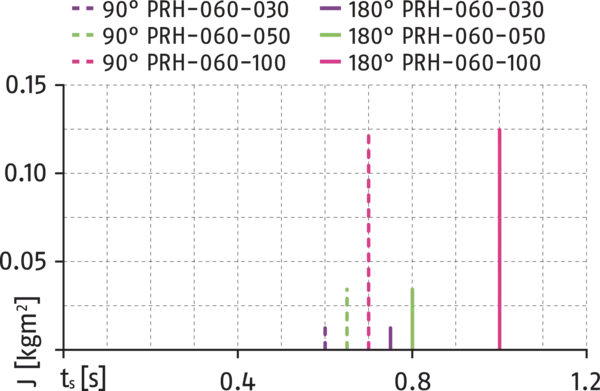

Schwenkzeitdiagramm

Dimensionen und max. Belastungen

Momente und Kräfte dürfen gleichzeitig auftreten.

Schwenkzeitdiagramm

- X-Achse:

- Schwenkzeit

- Y-Achse:

- Massenträgheit

- X-Achse oben:

- Zyklen pro Stunde

Allgemeine Hinweise zur Baureihe

Schwenkzeiten

sind reine Rotationszeiten des Moduls aus dem Stillstand bis zum Stillstand. Relaisschaltzeiten oder SPS-Reaktionszeiten sind nicht enthalten und bei der Ermittlung von Zykluszeiten zu berücksichtigen. Gegebenenfalls sind lastabhängige Pausenzeiten in die Zykluszeit miteinzurechnen.

Wiederholgenauigkeit

ist definiert als die Streuung der Zielposition bei 100 aufeinander folgenden Positionierzyklen.

Nennströme

dürfen dauerhaft anliegen. Bei allen Strömen oberhalb des Nennstroms bis zum Maximalstrom sind die Hinweise in der jeweiligen Produktdokumentation zu beachten.

Spitzendrehmoment

Die Spitzendrehmomente dienen als kurzfristige Antriebsreserve beim Beschleunigen und Verzögern.

Gehäusematerial

Aluminiumlegierung

Betätigung

servoelektrisch, über bürstenlosen DC-Servomotor

Wirkprinzip

über bürstenlosen DC-Servomotor direkt angetriebenes Harmonic Drive®-Getriebe

Lieferumfang

QR-Zettel zum Download der Inbetriebnahmesoftware, Sicherheitsinformationen (produktspezifische Anleitungen online verfügbar), Funktionsbaustein zur Ansteuerung über Siemens S7.

Gewährleistung

24 Monate

Lebensdauerkennwerte

auf Anfrage