EZU

Funktion

Sectional diagram

Sectional diagram

The brushless DC servomotor drives the three gear racks integrated in the slide-guided base jaws via a spur gear unit with rack-and-pinion principle. The spur gear unit reliably generates the gripping force, which remains constant even in the event of horizontal positioning errors of the workpiece or robot, thereby ensuring reliable centering of the workpiece as well as a high fault tolerance. The gripping force is generated without a minimum approach distance, which simplifies handling and speeds up the process.

An integrated absolute encoder ensures that the gripper is immediately ready for use even after an emergency stop or power failure. The gripping force maintenance, which is achieved in combination with a permanent magnet brake and a damping element in the drive train, reduces the risk of workpiece loss, which is detected by the integrated workpiece loss detection.

- 1

-

Sturdy and resistant T-slot guidance

for large finger lengths, external forces and moments. Optionally available as dust-tight version. - 2

-

Fully integrated and sealed control and power electronics

with status LEDs and M12 plug connectors for connecting the voltage supply and communication. - 3

-

High-resolution, output-side absolute encoder

for precise positioning of the gripper jaws with permanent absolute position feedback. - 4

-

Sealed drive train with spur gear and pinion/rack principle

enables reliable generation of the gripping force without a minimum approach distance. - 5

-

Brushless flat motor

for limited space and high torques due to external rotor. - 6

-

Electromagnetic brake

with additional mechanism for maintaining gripping force and position during standstill or power failure.

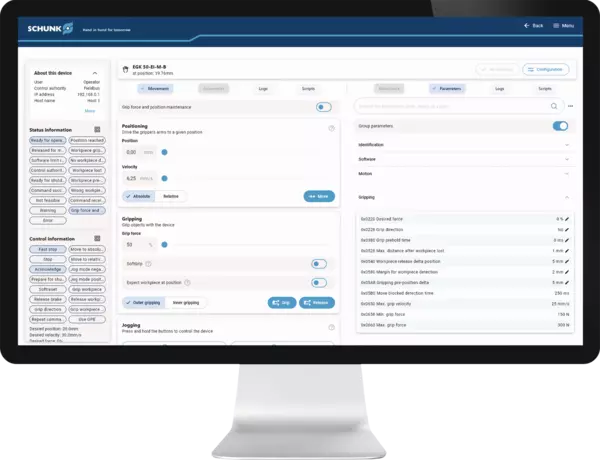

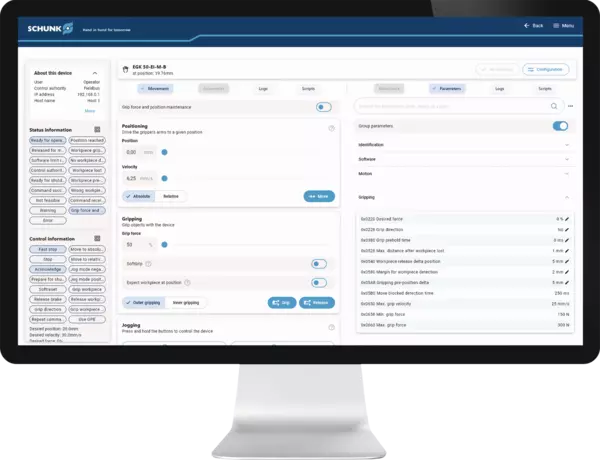

Commissioning app in the SCHUNK control center

Increased protection class with dust-tight version SD

Befestigungsmöglichkeit für Zusatzanbau

Konnektivität

Greifmodi

Software Service - Roboterintegration

Software Service - PLC integration

Commissioning app in the SCHUNK control center

The mechatronic grippers app simplifies commissioning, operation, diagnostics and service thanks to an extensive catalog of functions Users can control the gripper directly and perform application validation without the need for a PLC. The functions include network configuration, firmware updates, parameter adjustments and backups as well as comprehensive diagnostic options. The app is compatible with Windows and can be downloaded at schunk.com/downloads-software.

Increased protection class with dust-tight version SD

The dust-tight version increases the degree of protection against dust and liquids entering the guidance and base jaw. In combination with the sealed electronics (IP67), the dust-tight version is thus suitable for use in particularly harsh ambient conditions, such as for loading a grinding machine. The achieved protection of the guidance corresponds to the IP64 protection class and is thus absolutely dust-tight and protected against splashing water from all directions. You can find additional information on the product in the operating manual.

Befestigungsmöglichkeit für Zusatzanbau

Im Führungsgehäuse befinden sich zusätzliche Gewinde und Passungen zur Befestigung einer applikationsspezifischen Konstruktion um zusätzliche Funktionen zu realisieren. So kann zum Beispiel ein federndes Andrückelement, zum federgestützten Positionieren des Werkstückes gegen einen Anschlag, montiert werden.

Konnektivität

Ein breites Angebot an verfügbaren Kommunikationsschnittstellen vereinfacht den Umgang mit der Vielfalt an Steuerungs- und Roboterherstellern und sorgt für Zeitersparnis bei der Integration. Industrial Ethernet (PROFINET, EtherCAT, EtherNet/IP) ermöglicht die direkte Integration ohne zusätzliche Gateways in die Steuerungsumgebung führender SPS Hersteller am Markt. Mit der seriellen Schnittstelle Modbus RTU kann der Greifer ohne externe Kabelführung an den Werkzeugflansch führender Roboterhersteller angebunden werden. IO-Link ist unabhängig und bietet Flexibilität bei der Anbindung an weitere Netzwerke.

Greifmodi

Es stehen die Greifmodi BasicGrip und StrongGrip zur Verfügung.

BasicGrip: Greifgeschwindigkeit wird automatisch zur gewählten Greifkrafteinstellung optimiert, permanentes Nachgreifen ist möglich

StrongGrip: maximale Greifkraft wird erzeugt und anschließend durch die Greifkrafterhaltung gesichert, permanentes Nachgreifen ist innerhalb eines einstellbaren Zeitfensters möglich, Pausenzeiten zwischen Greifzyklen müssen berücksichtigt werden

Software Service - Roboterintegration

Für ein nahtloses Zusammenspiel zwischen Greifer und Roboter stehen Softwarebausteine für die Integration in die Robotersteuerung führender Hersteller zur Verfügung. Dadurch ist der Funktionsumfang des Greifers ohne zusätzlichen Programmieraufwand nutzbar und es kann direkt damit begonnen werden die Applikation zu programmieren.

Roboterkompatibilität: Universal Robots e-Series über Modbus RTU, FANUC CRX über Modbus RTU, ABB OmniCore C30 über EtherNet/IP, Yaskawa YRC1000micro über EtherNet/IP, Kassow Robots über Modbus RTU.

Software und weitere Kompatibilitätshinweise können unter schunk.com/downloads-software heruntergeladen werden.

Software Service - PLC integration

For seamless interaction between gripper and PLC control, function modules for the programming interface of leading manufacturers is available. This means that the gripper's range of functions can be used directly without any additional programming effort and programming of the application can be started immediately.

PLC compatibility: Siemens TIA Portal (PROFINET and IO-Link), Beckhoff TwinCAT (EtherCAT and IO-Link), Allen Bradley Studio 5000 Logix Designer (EtherNet/IP and IO-Link), Bosch Rexroth ctrlX (EtherCAT, only with Bosch Nexeed Automation).

Software and other compatibility notes can be downloaded at schunk.com/egu-software.

Application example

Application example

Flexible, cycle-time optimized loading and unloading of a machine tool. By using two grippers on the robot, the machine tool can be automatically loaded in a way that is optimized in terms of cycle time, meaning that productivity can be increased. Finished part and pre-machined part can be transported in one loading cycle. Due to the large and freely programmable jaw stroke of the gripper, different diameters can be gripped without having to change the gripper.

- 1

-

EZU double gripper for handling raw and finished parts

- 2

-

Machine tool with ROTA THW3 power lathe chuck