EZU

Fonction

Vue en coupe

Vue en coupe

Le servomoteur à courant continu entraîne les trois crémaillères intégrées dans les mors de base, par l'intermédiaire d'engrenages et du principe de pignon-crémaillère. Les engrenages droits génèrent avec fiabilité la force de préhension qui reste constante même en cas d'erreurs de position horizontale de la pièce ou du robot et assure ainsi le centrage fiable de la pièce ainsi qu'une tolérance d'erreur élevée. La force de préhension est générée sans distance d'approche minimale, ce qui simplifie la manipulation et accélère le processus.

Un codeur absolu intégré garantit que la pince est immédiatement prête à l'emploi, même après un arrêt d'urgence ou une coupure d'alimentation. Le maintien de la force de préhension, qui est obtenu par la combinaison d'un frein à aimant permanent et d'un élément d'amortissement dans la chaîne cinématique, réduit le risque de perte de pièces, qui est détecté par le système intégré de détection de perte de pièces.

- 1

-

Guidage à rainure en T résistant et robuste

pour des longueurs de doigts, des forces et moments externes importants. Disponible en option en version étanche à la poussière. - 2

-

Électroniques de commande et de puissance complètement intégrées et étanches

avec LED d'état et connecteurs M12 pour la connexion de l'alimentation et la communication. - 3

-

Codeur absolu haute résolution, côté sortie

pour un positionnement précis des doigts de la pince avec un retour de position absolu permanent. - 4

-

Entrainement étanche avec engrenage et principe pignon/crémaillère

permet une génération fiable de la force de préhension sans distance d'approche minimale. - 5

-

Moteur plat sans balai

pour un espace limité et des couples élevés grâce à un rotor externe. - 6

-

Frein électromagnétique

avec un mécanisme supplémentaire pour maintenir la force de préhension et la position pendant l'arrêt ou la panne de courant.

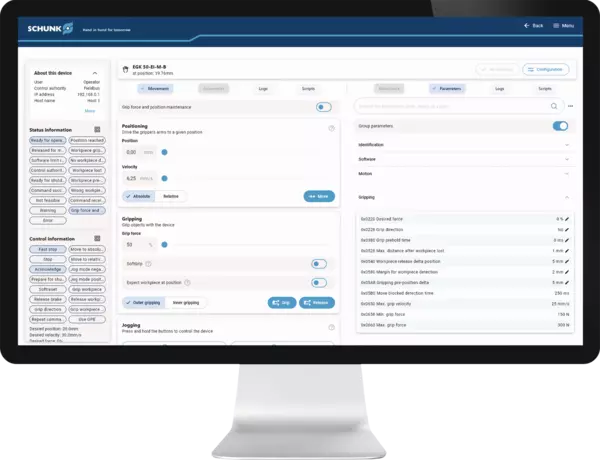

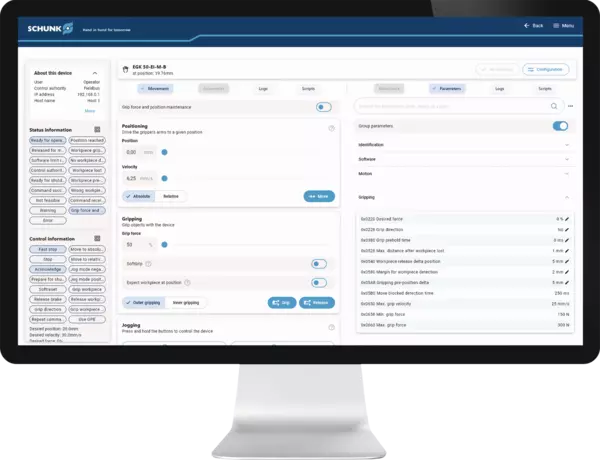

Commissioning app in the SCHUNK control center

Increased protection class with dust-tight version SD

Mounting option for additional attachment

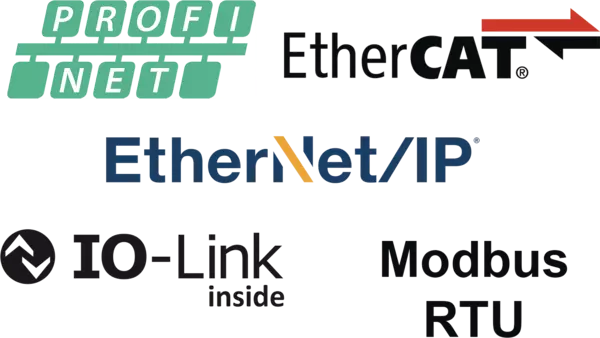

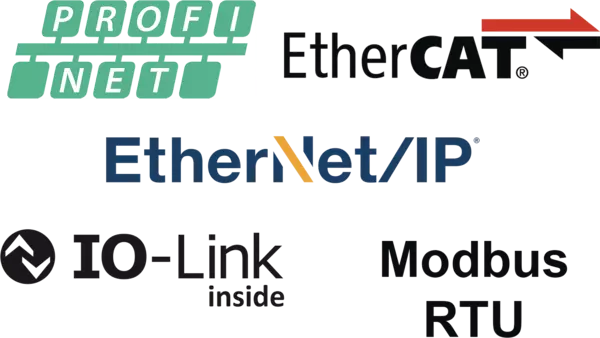

Connectivity

Gripping modes

Software Service - Robot integration

Software Service - PLC integration

Commissioning app in the SCHUNK control center

The mechatronic grippers app simplifies commissioning, operation, diagnostics and service thanks to an extensive catalog of functions Users can control the gripper directly and perform application validation without the need for a PLC. The functions include network configuration, firmware updates, parameter adjustments and backups as well as comprehensive diagnostic options. The app is compatible with Windows and can be downloaded at schunk.com/downloads-software.

Increased protection class with dust-tight version SD

The dust-tight version increases the degree of protection against dust and liquids entering the guidance and base jaw. In combination with the sealed electronics (IP67), the dust-tight version is thus suitable for use in particularly harsh ambient conditions, such as for loading a grinding machine. The achieved protection of the guidance corresponds to the IP64 protection class and is thus absolutely dust-tight and protected against splashing water from all directions. You can find additional information on the product in the operating manual.

Mounting option for additional attachment

Additional threads and fittings are located in the guidance housing for mounting an application-specific design in order to implement additional functions. For example, a spring-loaded pressure element can be fitted for spring-supported positioning of the workpiece against a stop.

Connectivity

A wide range of available communication interfaces simplifies handling with a wide variety of control and robot manufacturers and ensures time savings during integration. Industrial Ethernet (PROFINET, EtherCAT, EtherNet/IP) enables direct integration without additional gateways into the control environment of leading PLC manufacturers on the market. With the Modbus RTU serial interface, the gripper can be connected to the tool flange of leading robot manufacturers without external cable routing. IO-Link is independent and offers flexibility in connecting to other networks.

Gripping modes

The BasicGrip and StrongGrip gripping modes are available.

BasicGrip: The gripping speed is automatically optimized for gripping force adjustment, permanent re-gripping is possible

StrongGrip: Maximum gripping force is generated and then stored by the gripping force maintenance, permanent re-gripping is possible within an adjustable time window, pause times between gripping cycles must be taken into account

Software Service - Robot integration

For seamless interaction between gripper and robot, software modules for integration into the robot control system of leading manufacturers are available. This means that the gripper's range of functions can be used directly without any additional programming effort and programming of the application can be started immediately.

Robot compatibility: Universal Robots e-Series via Modbus RTU, FANUC CRX via Modbus RTU, ABB OmniCore C30 via EtherNet/IP, YASKAWA YRC1000micro via EtherNet/IP, Kassow Robots via Modbus RTU.

Software and other compatibility notes can be downloaded at schunk.com/egu-software.

Software Service - PLC integration

For seamless interaction between gripper and PLC control, function modules for the programming interface of leading manufacturers is available. This means that the gripper's range of functions can be used directly without any additional programming effort and programming of the application can be started immediately.

PLC compatibility: Siemens TIA Portal (PROFINET and IO-Link), Beckhoff TwinCAT (EtherCAT and IO-Link), Allen Bradley Studio 5000 Logix Designer (EtherNet/IP and IO-Link), Bosch Rexroth ctrlX (EtherCAT, only with Bosch Nexeed Automation).

Software and other compatibility notes can be downloaded at schunk.com/egu-software.

Application example

Application example

Flexible, cycle-time optimized loading and unloading of a machine tool. By using two grippers on the robot, the machine tool can be automatically loaded in a way that is optimized in terms of cycle time, meaning that productivity can be increased. Finished part and pre-machined part can be transported in one loading cycle. Due to the large and freely programmable jaw stroke of the gripper, different diameters can be gripped without having to change the gripper.

- 1

-

EZU double gripper for handling raw and finished parts

- 2

-

Machine tool with ROTA THW3 power lathe chuck