Co-act EGP-C 40-N-N-KTOE

Ident.-Nr. 1321170

- Hub pro Backe: 6 mm

- Min. Greifkraft: 35 N

- Max. Greifkraft: 140 N

- Spannungsversorgung: 24 V

- Max. Strom gesamt: 2 A

- Max. Umgebungstemperatur: 55 °C

Technische Details

| Passender Roboter | KUKA LBR iiwa 7/14 |

|---|---|

| Roboterflansch | Medien-Flansch Touch elektrisch |

| LED-Lichtband | integriert |

| Darstellbare Farben | grün, gelb, rot |

| Integrierte Sensoren | ja, 2-fach induktiv |

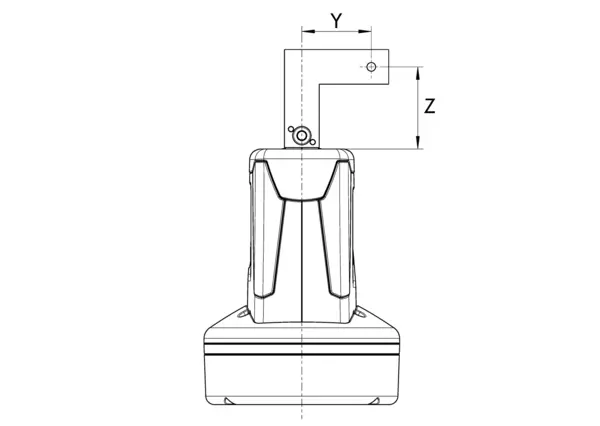

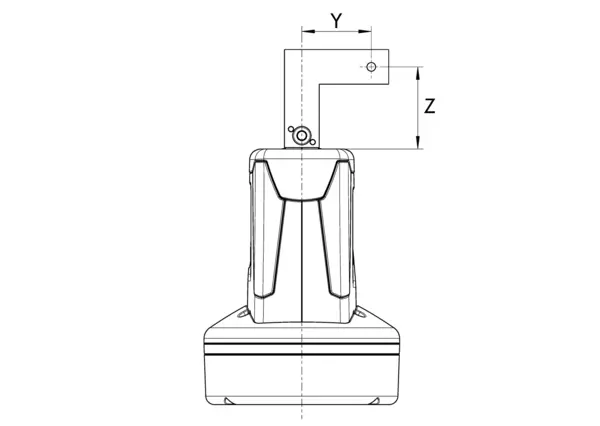

| Länge X [mm] | 93.8 |

| Breite Y [mm] | 90.2 |

| Höhe Z [mm] | 123.0 |

| Hub pro Backe [mm] | 6.0 |

| Min. Greifkraft [N] | 35.0 |

| Max. Greifkraft [N] | 140.0 |

| Min. Kraft pro Backe [N] | 17.5 |

| Max. Kraft pro Backe [N] | 70.0 |

| Empfohlenes Werkstückgewicht [kg] | 0.7 |

| Max. zulässige Fingerlänge [mm] | 50.0 |

| Max. zulässige Masse pro Finger [kg] | 0.08 |

| Wiederholgenauigkeit [mm] | 0.02 |

| Schließzeit [s] | 0.2 |

| Öffnungszeit [s] | 0.2 |

| Eigenmasse [kg] | 0.62 |

| Min. Umgebungstemperatur [°C] | 5.0 |

| Max. Umgebungstemperatur [°C] | 55.0 |

| Schutzart IP | 30 |

| Kabelstecker/Kabelende | M12 |

| Kabellänge [mm] | 70.0 |

| Nennspannung [V] | 24.0 |

| Nennstrom [A] | 0.2 |

| Max. Strom [A] | 2.0 |

| Reglerelektronik | integriert |

| Kommunikationsschnittstelle | digitale I/O |

| Anzahl digitaler Eingänge | 4.0 |

| Anzahl digitaler Ausgänge | 2.0 |

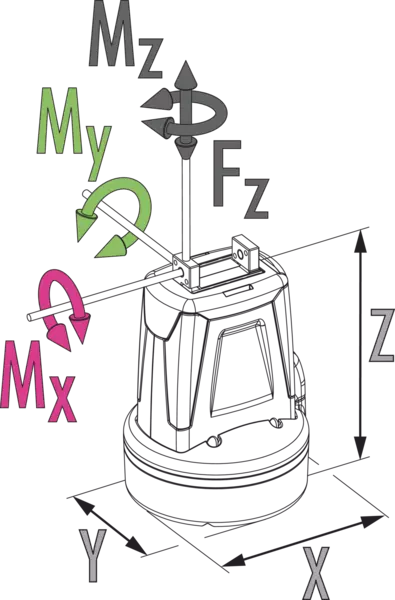

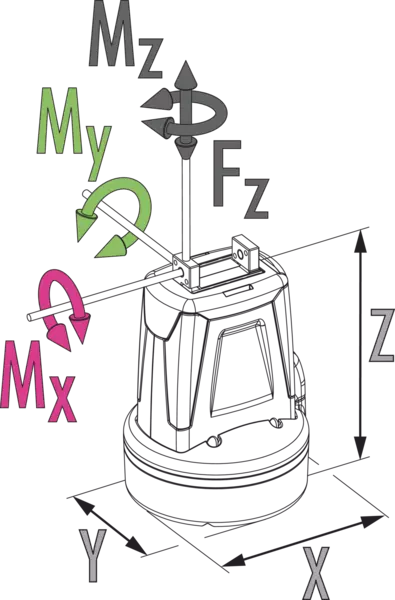

| Moment Mx max. [Nm] | 1.5 |

| Moment My max. [Nm] | 2.0 |

| Moment Mz max. [Nm] | 4.0 |

| Max. Kraft axial Fz max. [N] | 170.0 |

Dimensionen und max. Belastungen

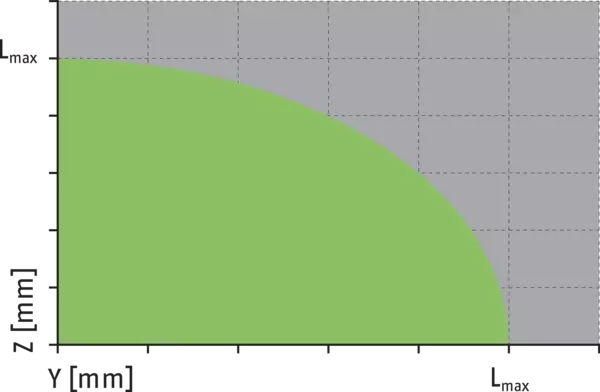

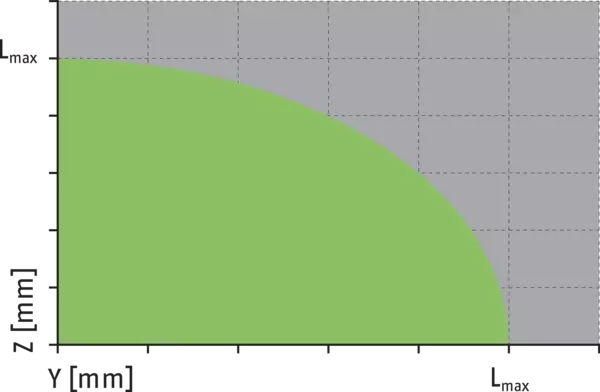

Maximal zulässige Auskragung

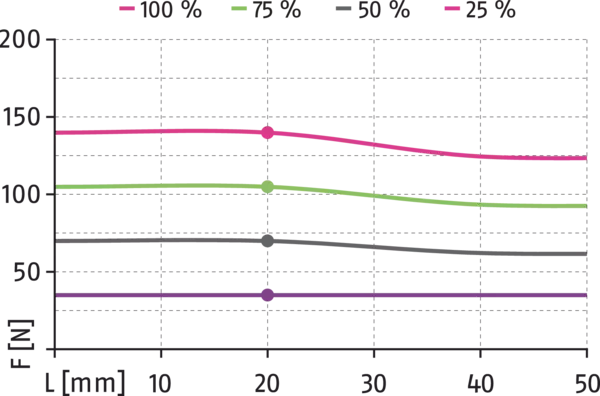

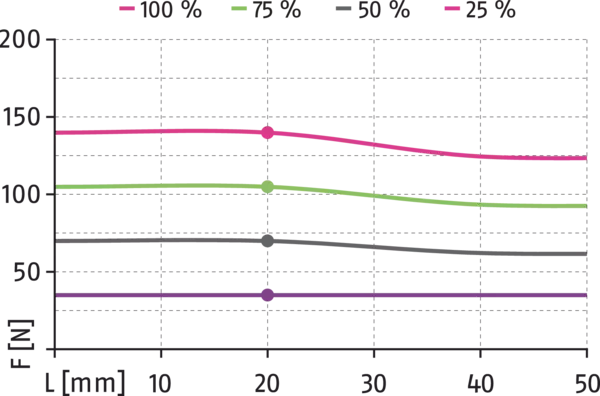

Greifkraft

Maximal zulässige Auskragung

Dimensionen und max. Belastungen

Die angegebenen Momente und Kräfte sind statische Werte, gelten je Grundbacke und dürfen gleichzeitig auftreten. Die Belastungen dürfen zusätzlich zu dem durch die Greifkraft erzeugten Moment auftreten.

Maximal zulässige Auskragung

Greifkraft

- X-Achse:

- Fingerlänge

- Y-Achse:

- Greifkraft

Maximal zulässige Auskragung

Lmax entspricht der maximal zulässigen Fingerlänge, siehe technische Datentabelle.

- green

- Zulässiger Bereich

- grey

- Unzulässiger Bereich

Allgemeine Hinweise zur Baureihe

Greifkraft

ist die arithmetische Summe der an jeder Greifbacke wirkenden Greifkraft, im Abstand P (siehe Zeichnung). Weitere Hinweise siehe Detaillierte Funktionsbeschreibung.

Fingerlänge

wird ab derselben Bezugsfläche wie der Abstand P in Richtung der Hauptachse gemessen.

Wiederholgenauigkeit

ist definiert als Streuung der Endlage bei 100 aufeinanderfolgenden Hüben.

Werkstückgewicht

wird errechnet bei Kraftschluss mit einem Haftreibwert von 0,1 und einer Sicherheit von 2 gegen Rutschen des Werkstücks bei Erdbeschleunigung g. Bei Formschluss ergeben sich deutlich höhere zulässige Werkstückgewichte. Weitere Hinweise siehe Montage- und Betriebsanleitung.

Schließ- und Öffnungszeiten

sind reine Bewegungszeiten der Grundbacken ohne anwendungsspezifische Greiferfinger. SPS-Reaktionszeiten sind nicht enthalten und bei der Ermittlung von Zykluszeiten zu berücksichtigen.

Wirkprinzip

Ritzel-Zahnstangen-Prinzip

Gehäusematerial

Polyamid mit Glasfaser-Zusatz

Grundbackenmaterial

Stahl

Betätigung

servoelektrisch, über bürstenlosen DC-Servomotor

Gewährleistung

siehe Montage- und Betriebsanleitung

Lebensdauerkennwerte

auf Anfrage

Lieferumfang

Beipack mit Adapterflansch, Befestigungsmaterial und Innensechskant-Schlüssel, Montage- und Betriebsanleitung mit Konformitäts- und Einbauerklärung, Sicherheitsinformationen