RP 1216-X-H

ID 313246

Prodotti alternativi:

- Stroke per jaw: 3 mm

- Angle of rotation: 190 °

- Opening force: 130 N

- Torque: 0.38 Nm

Specifiche tecniche

| Stroke per jaw [mm] | 3.0 |

|---|---|

| Opening force [N] | 130.0 |

| Min. spring force [N] | 40.0 |

| Torque [Nm] | 0.38 |

| Angle of rotation [°] | 190 |

| Recommended workpiece weight [kg] | 0.45 |

| Air consumption for gripping [cm³] | 1.1 |

| Air consumption for swiveling [cm³] | 4.8 |

| Weight [kg] | 0.64 |

| Nominal operating pressure [bar] | 6.0 |

| Max. operating pressure [bar] | 8.0 |

| Min. operating pressure for gripping [bar] | 5.0 |

| Min. operating pressure for swiveling [bar] | 3.0 |

| Closing time [s] | 0.025 |

| Opening time [s] | 0.015 |

| Max. permissible finger length [mm] | 50.0 |

| Max. permissible weight per finger [kg] | 0.1 |

| IP protection class | 40 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 60.0 |

| Repeat accuracy for gripping [mm] | 0.02 |

| Repeat accuracy for swiveling [°] | 0.049 |

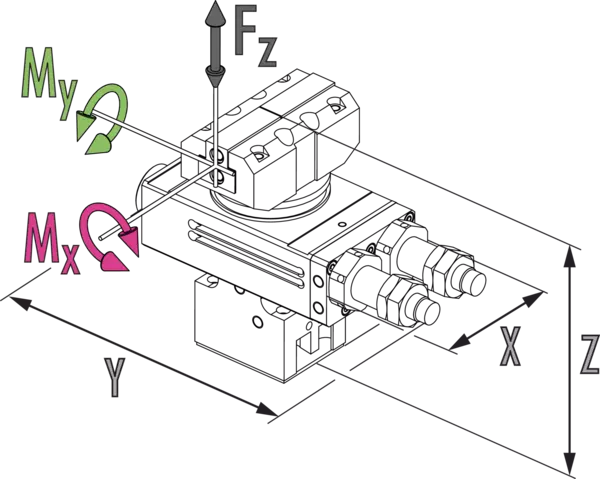

| Length X [mm] | 117.0 |

| Width Y [mm] | 43.0 |

| Height Z [mm] | 122.0 |

| Moment Mx max. [Nm] | 5.0 |

| Moment My max. [Nm] | 10.0 |

| Max. axial force Fz max. [N] | 100.0 |

| Rotation adapter version | yes |

Dimensions and maximum loads

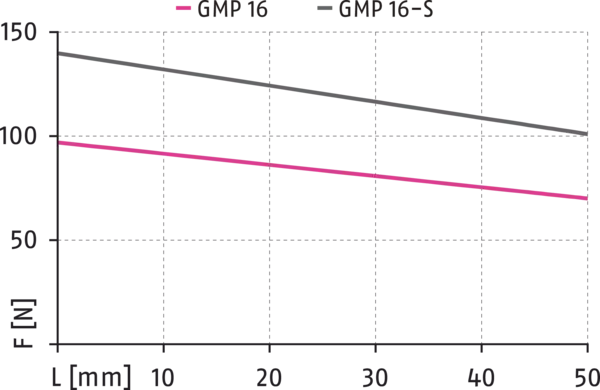

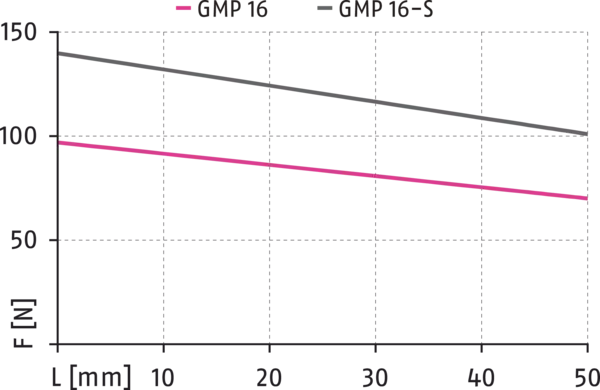

Gripping force I.D. gripping

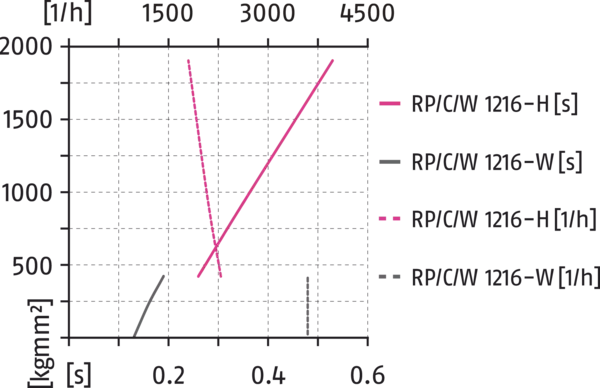

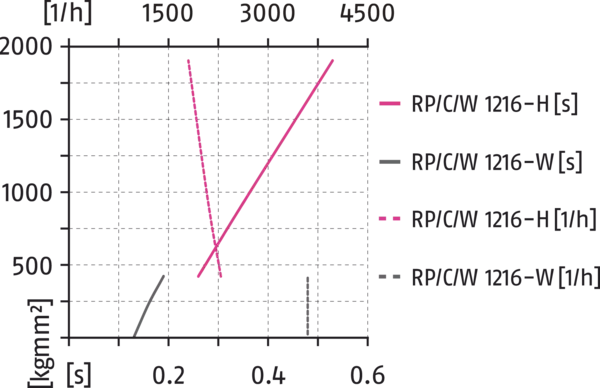

Max. permissible inertia J*

Dimensions and maximum loads

The indicated moments and forces are statical values, apply for each base jaw and may appear simultaneously. Loads may additionally occur to the moment produced by the gripping force itself.

Gripping force I.D. gripping

- Asse X:

- Finger length

- Asse Y:

- Gripping force

Max. permissible inertia J*

- Asse X:

- Swiveling time

- Asse Y:

- Mass moment of inertia

- Asse X superiore:

- Cycles per hour

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw.

Pinion position

is always shown in the left end position. The pinion rotates from here to the right in clockwise direction. The arrow makes the direction of rotation clear.

Pinion screw connection diagram

When setting a swivel angle smaller than 90°, the left end stop must be completely turned in. This means that the left end position has a screw connection diagram on the pinion which is clockwise turned by 90° compared to the main view, which shows a swivel angle of 180°.

Finger length

measured from the screw surface of the base jaw in the direction of the main axis. Failure to comply with the max. permissible finger length will result in increased wear.

Layout or control calculation

For configuration or control calculation of the units, we recommend to use our Toolbox software, which is available online. Verifying the sizing of the selected unit is absolutely necessary, as otherwise overloading may occur.

Operating principle

Combination of rack and pinion with double piston drive

Housing material

Aluminum alloy, anodized

Base jaw material

Steel

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Warranty

24 months

Scope of delivery

Completely ready for operation without bracket for proximity switch and without proximity switch

Gripping force maintenance

possible by using the version with mechanical gripping force maintenance or pressure maintenance valve SDV-P