航空航天业是复杂性最高的领域之一,它融合了信息技术、机器人技术、测量与控制技术等多个领域的要素。材料、组件和系统必须能够承受极端应力。完善的质量保证体系确保采取一切措施防止错误发生。尽管创新水平高于平均水平,时间因素同样发挥着决定性作用。SCHUNK是您航空航天领域的可靠合作伙伴。我们既支持飞机制造项目,也助力航天旅行的研发活动。

携手舒克工程,我们将共同将航空航天领域的特殊需求转化为解决方案:定制化的抓取、夹持与搬运技术,以及确保可重复质量、部件保护和全流程高可靠性的仿真技术。

在航空航天工业的极端条件下,结构组件必须符合最高标准。这些部件是构成飞机和航天器的支柱,不仅需要极高的稳定性,还必须兼具低重量和高强度。材料科学的持续创新推动了对极耐用轻质结构部件的开发。这些革命性的进步对于飞机和航天器的效率、性能和安全性至关重要。

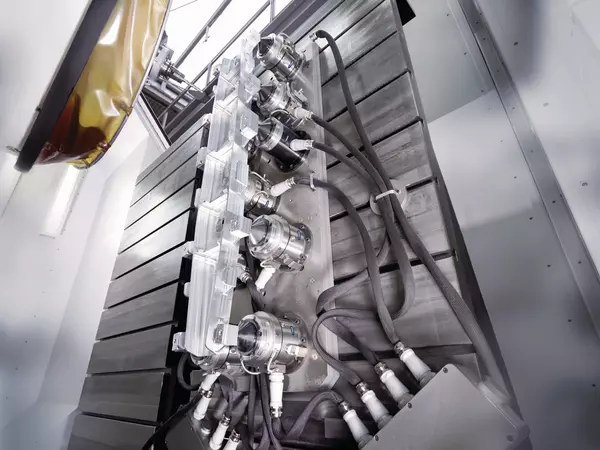

结构部件对装夹提出了很高的要求,而任何调整都需要极高的金钱和时间成本。凭借可控的灵活性,VERO-S Aviation 能够简单有效地夹持和松开组件,极大减少了装配需求。

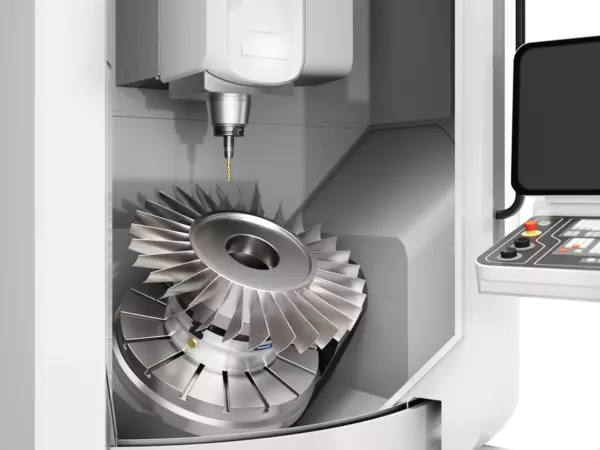

在航空航天工业中,传动机构部件会影响飞机的性能和效率,发挥着关键作用。从涡轮叶片到高温合金,这些部件必须能够承受最高的负荷。随着材料技术和精密制造的进步,现在已经能开发出质量更轻,且可以承受极端温度和压力的发动机零件。在该领域的持续创新对于提升燃油效率、减少排放和提高航空发动机的整体性能至关重要。

在夹持例如壳体和涡轮机部件等精密部件时,需要低变形度装夹。这就是我们在确保加工过程完整性的同时,满足最高精度要求的方式,即使是旋转性对称部件也是如此。

起落架部件在航空航天工业中也非常重要,它们对飞机的安全着陆和起飞有着关键性作用。从着陆减震器到制动系统,这些高度专业化的部件必须能够承受极端载荷。得益于材料科学和工程领域的持续创新,底盘零件变得更轻、更耐用、更高效。设计和生产在考虑精度的同时需要达到安全性、减重和性能等极为苛刻的要求,这也为现代航空航天技术的发展做出了重大贡献。

在夹持飞机轮辋时,我们尤其关注如何将变形风险降至最低。在这类应用中,我们使用低变形夹持的 6 爪卡盘。以此确保精密加工和满足质量标准。

在 CoLab(SCHUNK 应用中心),我们与您共同开展应用测试工作。我们还可以提供可行性研究、流程分析及演示。让您可以在调试期间最大限度地降低风险并节省时间。咨询您的 SCHUNK 联系人,我们期待与您讨论并开发应用。