如果您想加快生产,就没有办法绕过自动化。在兼具生产力和经济性的企业中,创新、定制解决方案是实现健康生产的基石。在国际金属加工展览会 AMB 上,我们将展示各种自动化方案,用于提高制造过程的效率,使公司适应未来。

尽管存在熟练工人短缺和成本压力,但自动化仍是生产率和成本效益的关键。但是,合理的自动化并不只在于机床本身。为了充分发挥设备的生产潜力,需确保上下料过程中的可靠性和速度。作为刀具和工件夹持、抓取技术和自动化技术方面的专家,我们既提供自动化生产的机床内部所需的多种部件,也提供与自动化上下料过程相关的各种组件。

我们期待与您面对面交流!

根据您对工件、批量、制造工艺和机床的个性化要求,提供多种实现机床自动化选项。我们将从方案初期就为您提供支持,确保您了解各类机床自动化方案,并做出最适合的选择。基于多年积累的经验,我们将与您密切合作,为您的生产流程找到合适的自动化模式,提高机床的生产率,实现面向未来的可持续发展。

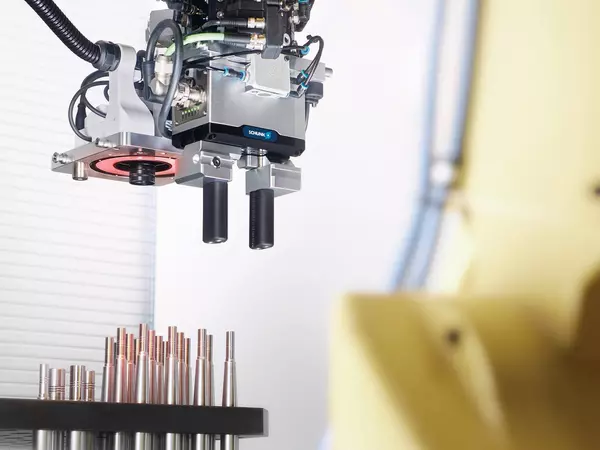

通过实际应用示例,体验借助机械手和轴系统实现的各种自动工件搬运方案。广受好评的机电一体化机械手系列 EGU 例如,多种可选项,实现灵活搬运类型多样的工件我们正在进一步扩展产品组合,并于 AMB 期间展示,其中包含专用于圆形工件抓取的三指机械手。

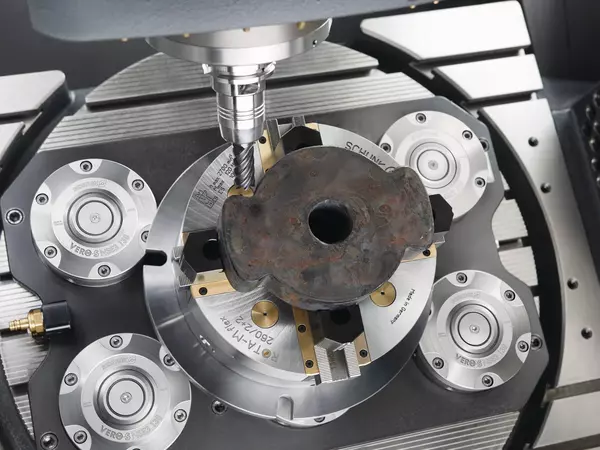

SCHUNK 还提供适合于各种工件夹持的手动、动力和智能化解决方案。不断优化和扩展现有的产品组合。展会期间,您可以通过 MAGNOS、TANDEM、KONTEC 或 VERO-S 来体验 SCHUNK 工件夹持技术的多种可能性和应用场景,

同时体验最新产品,例如全新的 ROTA-ML flex 2+2 ,一款灵活的 4 爪补偿卡盘,其重量已减轻了多达 40%。

在 AMB 展会上,体验如何分析和优化工艺流程 iTENDO² 探索新的 iTENDO² 智能刀柄的适用场景,无需接口,将智能实时传感器系统直接置入机床内。我们关注您的应用情况,通过密切合作为您找到最合适的刀具夹持系统。您也可以了解我们的专业解决方案和 easyToolholder 刀柄配置器,该工具专用于标准解决方案无法满足的情况。

标准组件并不总能解决所有问题。为此,我们提供 SCHUNK 系统工程服务:从简单适配到重新开发复杂的个性化夹持或自动化解决方案,一切皆有可能。除了与我们的客户服务团队专人沟通,我们的数字化工具还能够为个性化配置提供支持: easyJAW (卡爪) easyToolholder (刀柄)、FGR(机械手手指)、ELG 和 PLG 以及线性模块配置器。使用这些配置器,几次点选后即可获得专用解决方案,既节省时间,又可以降低实施成本。