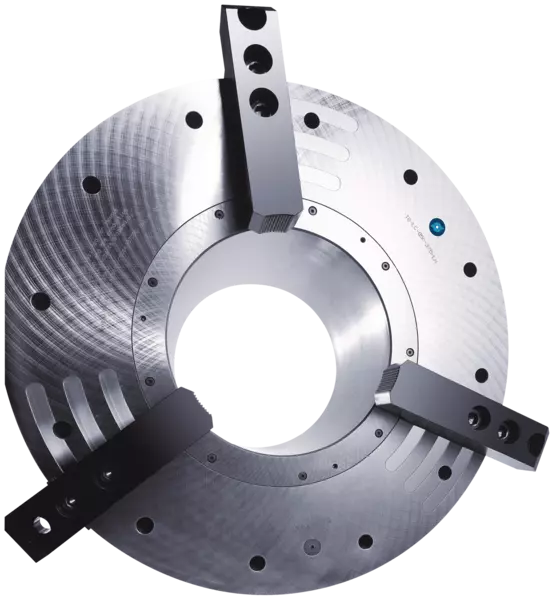

ROTA TB-LH

Pneumatic 3-jaw power chuck with dual stroke system

This product has been discontinued and is no longer available.

Phased out date: Jun 30, 2023

Pneumatic 3-jaw front-end chuck with fast stroke and clamping stroke and a large through-hole for O.D. clamping.

Description

Advantages – Your benefits

- Precision wedge hook pneumatic chuck for top quality demands

Allows excellent machining results - Large through-hole

Machining all standard pipe diameters - High efficiency of the wedge hook system

Process-reliable clamping due to high clamping forces - Optimized lubrication system

Consistently high clamping forces ensured - Monitoring of the opening and closing process

Process reliable operation of the lathe chuck - Pneumatic cylinder integrated in the chuck

Especially suited to lathes without a hydraulic cylinder - Perfectly suitable for lathes without hydraulic cylinder

Fast and easy changeover from manual lathe chucks - Air supply via a distributor ring

Very simple control of the chuck - High clamping forces at system pressure

Ensure process reliability during machining - All sides of the functional parts are hardened and ground

Ensures a long service life

Options and special information

- The technology of the self-contained power chucks with fast and extended stroke (LH) is based on a chuck piston with two different gear transmission ratios. This technology can be used for O.D. clamping only!

- Due to this principle of function, the chuck has a low air consumption, a large and fast jaw stroke combined with a maximum clamping force. Due to the very large through-hole these chucks are suitable for machining of large pipes. Moreover, the machining of adapter plate components is also possible.

- The chuck contains an air supply system on the distributor ring. Therefore no rotary feed-throughs are necessary.