ELG 120-XXX-1-ASY

- 最小单爪行程: 100 mm

- 最大单爪行程: 400 mm

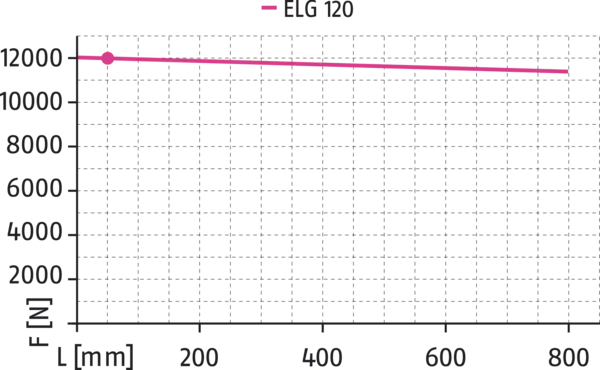

- 抓取力: 12000 N

- 最高环境温度: 55 °C

技术细节

| 手指版本 | 短 |

|---|---|

| 同步 | 异步 |

| 最小单爪行程 [mm] | 100.0 |

| 最大单爪行程 [mm] | 400.0 |

| 抓取力 [N] | 12000.0 |

| 最小抓取力保持*** [%] | 80 |

| 重量* [kg] | 42.0 |

| 每 1 mm 行程的额外质量** [kg] | 0.09 |

| 闭合时间 [s] | 0.98 |

| 打开时间 [s] | 0.98 |

| 最大允许速度(定位) [mm/s] | 170.0 |

| 最大允许速度(抓取) [mm/s] | 10.0 |

| 建议工件重量 [kg] | 60.0 |

| 重复精度(单向定位) [mm] | 0.1 |

| 最大允许手指长度 [mm] | 300.0 |

| 每个手指的最大允许重量 [kg] | 35.0 |

| 最低环境温度 [°C] | 5.0 |

| 最高环境温度 [°C] | 55.0 |

| IP 防护等级 | 20 |

| 带波纹管,防护等级 IP | 44 |

| 静止扭矩(轴直径 8/9 mm) [Nm] | 1.79 |

| 静止扭矩(轴直径 11/14 mm) [Nm] | 2.19 |

| 静止扭矩(轴直径 19 mm) [Nm] | 2.69 |

| 静止扭矩(轴直径 22 mm) [Nm] | 3.15 |

| 静止扭矩(轴直径 24 mm) [Nm] | 3.58 |

| 最大驱动速度(轴直径 8/9 mm) [1/min] | 5600.0 |

| 最大驱动速度(轴直径 11/14 mm) [1/min] | 4600.0 |

| 最大驱动速度(轴直径 19 mm) [1/min] | 3800.0 |

| 最大驱动速度(轴直径 22 mm) [1/min] | 3200.0 |

| 最大驱动速度(轴直径 24 mm) [1/min] | 2800.0 |

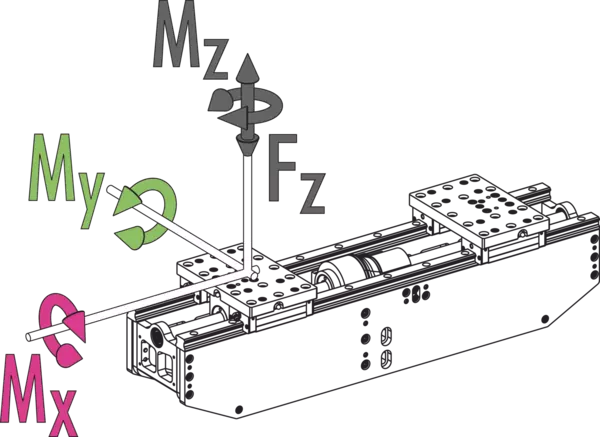

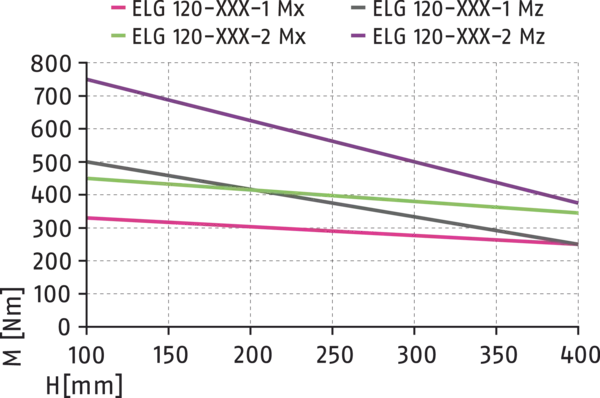

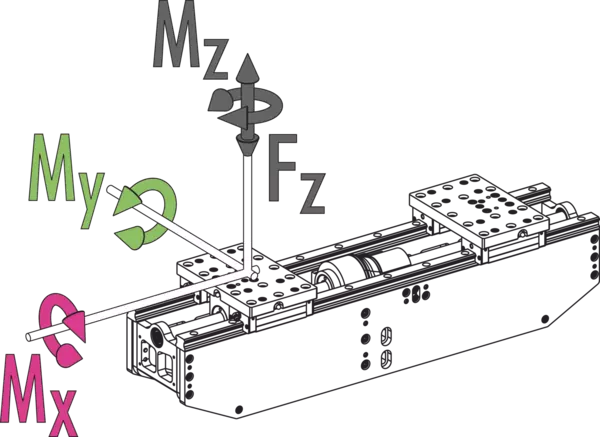

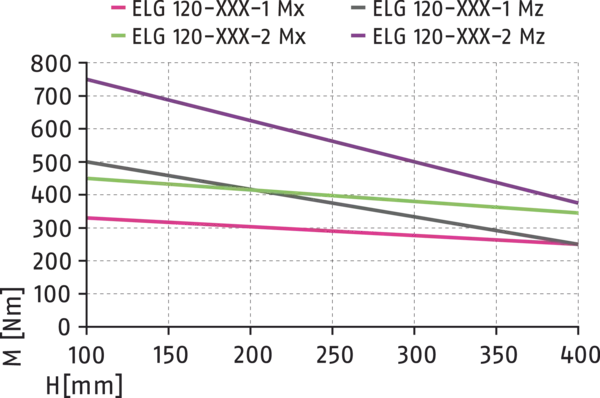

| 力矩 Mx max. [Nm] | 330.0 |

| 力矩 My max. [Nm] | 600.0 |

| 力矩 Mz max. [Nm] | 500.0 |

| 最大轴向力 Fz max。 [N] | 4000.0 |

* 基于所示的基础版本,单指行程为 100 mm,无额外选配件

** 指不含额外选配件的基础版本

*** 针对使用带电机制动器的电机和/或使用位置夹紧选项的情况

最大负载

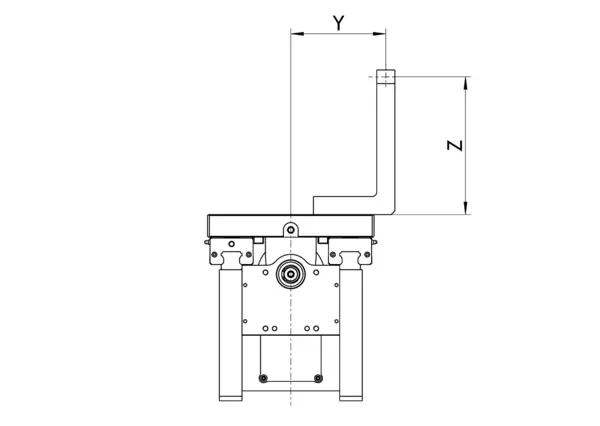

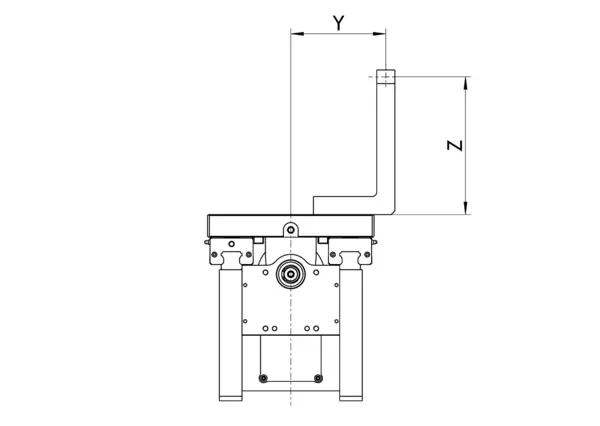

最大允许手指投影

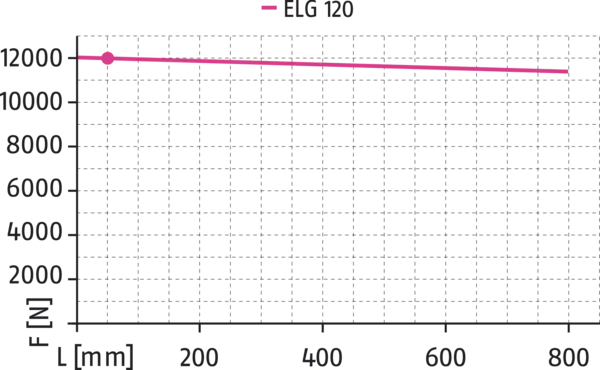

抓取力

手指型号:短手指长度

手指型号:长手指长度

最大负载

所示力矩和力为静态值,适用于每个基爪,且可能会同时出现。除抓取力自身产生的力矩外,还可能产生负载。另请参考力矩负载的示意图。

最大允许手指投影

抓取力

- X 轴:

- 手指长度

- Y 轴:

- 抓取力

手指型号:短手指长度

Lmax 等于最大允许手指长度。请参见技术参数表。

- green

- 允许的范围

- grey

- 不允许的范围

手指型号:长手指长度

- green

- 允许的范围

- grey

- 不允许的范围

General notes about the series

Gripping force

when the arithmetic sum of the individual force applied to each jaw at distance P (see illustration) on standstill torque of the motor.

Standstill torque

required standstill torque of the motor to achieve the specified gripping force depending on the motor shaft diameter. This torque must not be exceeded. The required standstill torque for the asynchronous version is halved.

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Gripping force maintenance

A gripping force of at least 80% of the originally applied gripping force can be reliably maintained in the event of an emergency stop situation or a voltage drop due to an electric holding brake (using motors with motor brake and/or utilizing the position clamping option).

Repeat accuracy (positioning, unidirectional)

defined as the spread of the actual position of the base jaws after 100 consecutive movements to a target position from the same direction under constant conditions.

Closing and opening times

When gripping, the speed must be adapted as described in the operating manual so that the closing and opening times can increase. The times specified are only the movement times of the base jaws at max. speed, max. acceleration without electrical restrictions, and observance of the maximum permissible masses per finger.

How to get to the online configurator

The configurator can be accessed via the SCHUNK website or via https://schunk.com/us/en/konfigurator-elg available directly.

Operating principle

Spindle drive

Housing material

Aluminum

Base jaw material

Aluminum

Actuation

electrically via an adaptable servo drive

Warranty

12 months

Scope of delivery

Gripper in the ordered variant, accessory kit (centering sleeves/detailed contents see operating manual) and safety information. Product-specific instructions can be downloaded at schunk.com/downloads-manuals.