EGL 90-PN

ID 1302877

Alternative products:

- Stroke per jaw: 42.5 mm

- Min. gripping force: 50 N

- Max. gripping force: 600 N

- Power supply: 24 V

- Max. ambient temperature: 55 °C

Technical details

| Zdvih na čelist [mm] | 42.5 |

|---|---|

| Min. uchopovací síla [N] | 50.0 |

| Max. uchopovací síla [N] | 600.0 |

| Doporučená hmotnost obrobku [kg] | 3.0 |

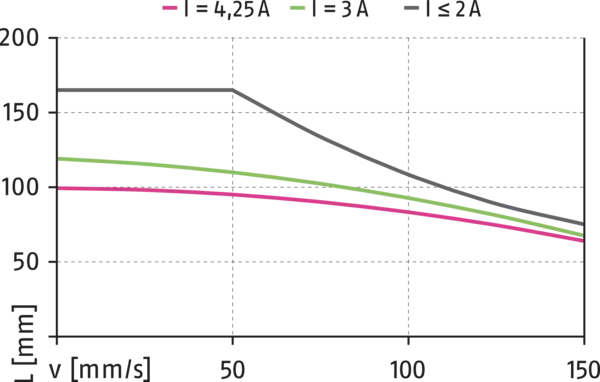

| Max. přípustná délka prstu [mm] | 165.0 |

| Max. přípustná hmotnost jednoho prstu [kg] | 0.5 |

| Opakovatelná přesnost [mm] | 0.05 |

| Doba zavření [s] | 0.7 |

| Doba otevření [s] | 0.7 |

| Max. rychlost [mm/s] | 150.0 |

| Max. zrychlení [mm/s²] | 2500.0 |

| Vlastní hmotnost [kg] | 1.8 |

| Min. okolní teplota [°C] | 5.0 |

| Max. okolní teplota [°C] | 55.0 |

| Třída ochrany IP | 46 |

| Třída čistého prostoru ISO 14644-1:2015 | 4 |

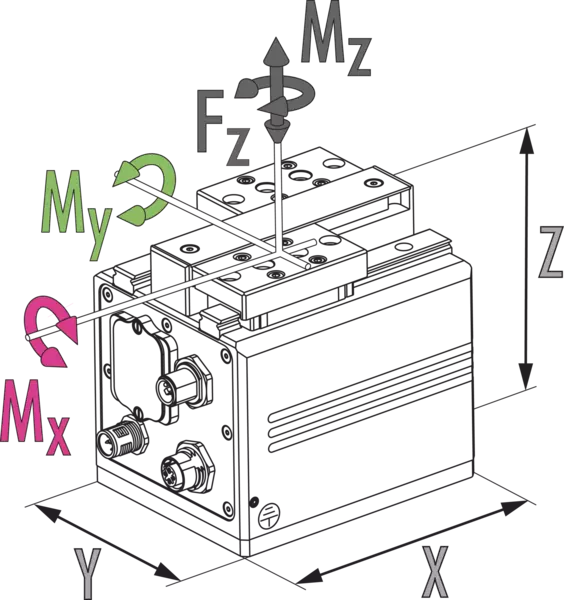

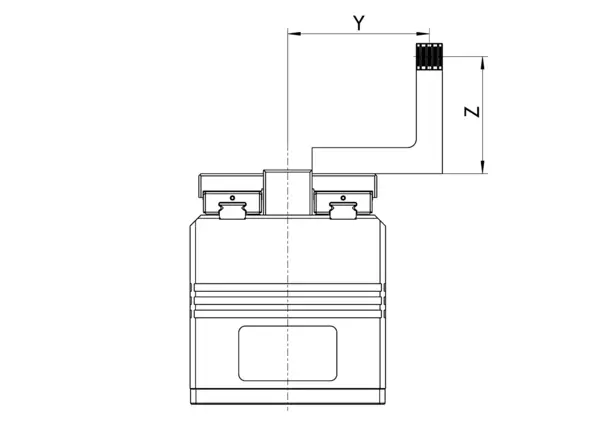

| Délka X [mm] | 112.0 |

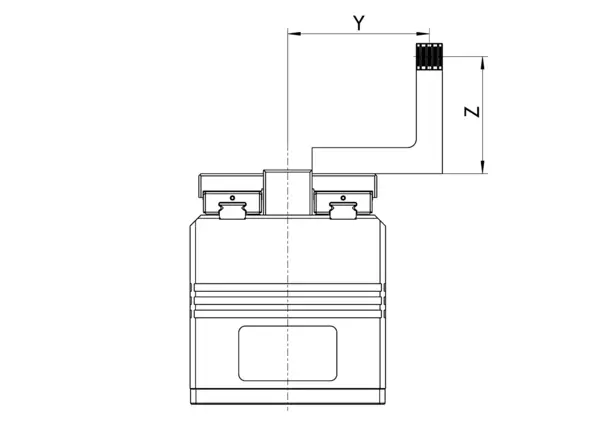

| Šířka Y [mm] | 90.0 |

| Výška Z [mm] | 108.0 |

| Řídicí elektronika | integrované |

| Jmenovité napětí [V] | 24.0 |

| Komunikační rozhraní | PROFINET |

| Parametrizační rozhraní | USB |

| Max. výstupní výkon [A] | 2.5 |

| Max. logický proud [A] | 0.5 |

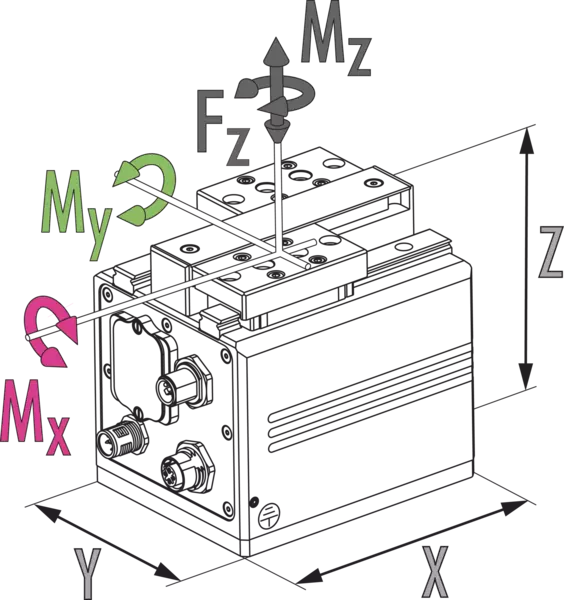

| Max. moment Mx [Nm] | 20.0 |

| Max. moment My [Nm] | 20.0 |

| Max. moment Mz [Nm] | 20.0 |

| Max. axiální síla Fz max. [N] | 400.0 |

Rozměry a maximální zatížení

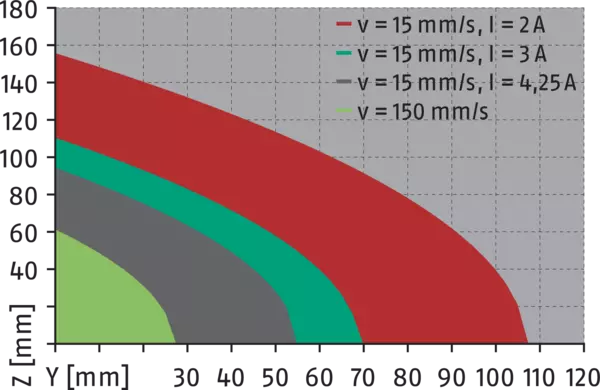

Maximální přípustný přesah

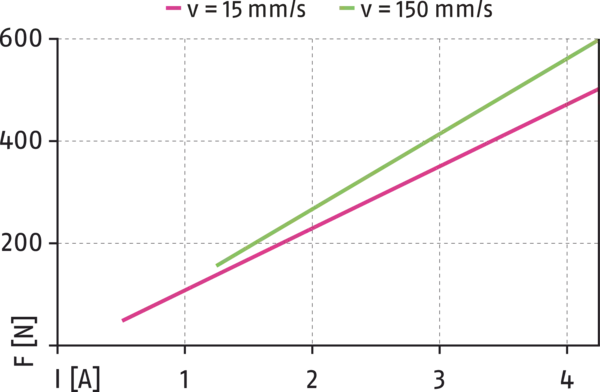

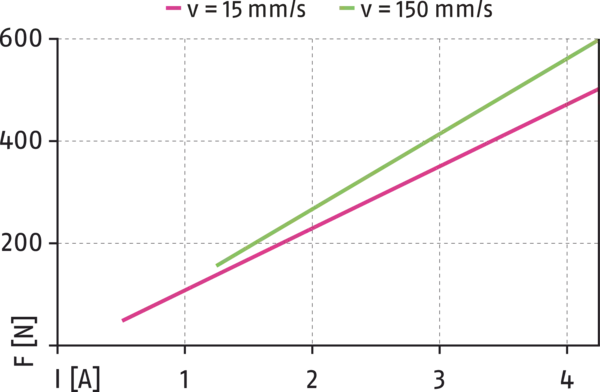

Uchopovací síla

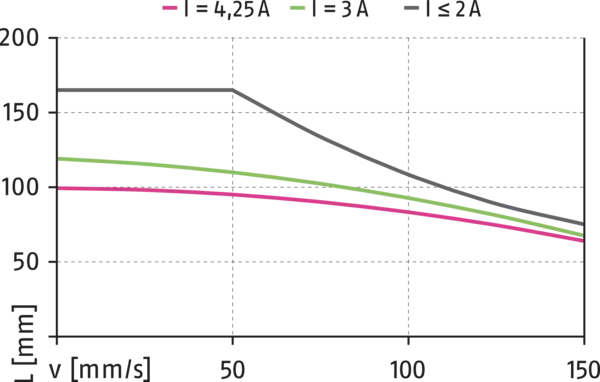

Délka prstu

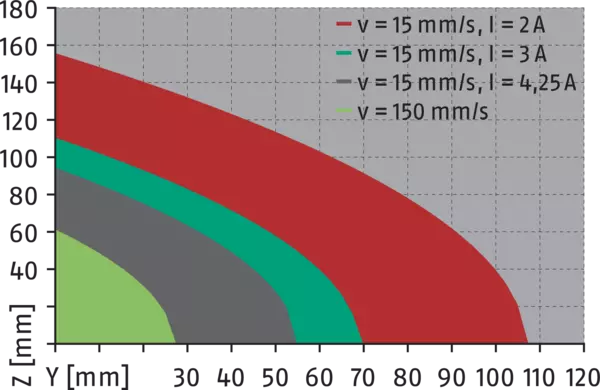

Maximální přípustný přesah

Snížení

Rozměry a maximální zatížení

Uvedené momenty a síly jsou statické hodnoty platné pro každou základní čelist a mohou se objevovat současně. Kromě momentu tvořenému samotnou uchopovací silou mohou navíc působit další zatížení.

Maximální přípustný přesah

Uchopovací síla

- X-axis:

- Proud motoru

- Y-axis:

- Uchopovací síla

Délka prstu

- X-axis:

- Rychlost čelisti

- Y-axis:

- Délka prstu

Maximální přípustný přesah

- grey

- Nepřípustný rozsah

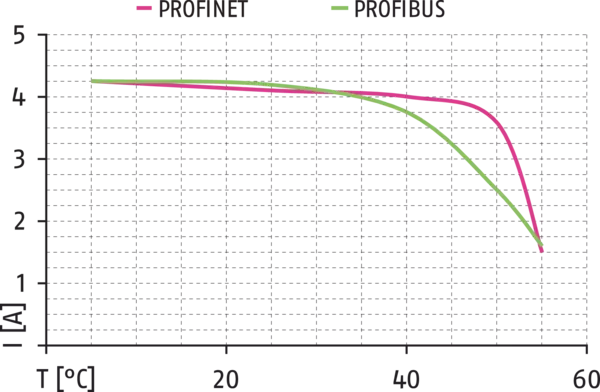

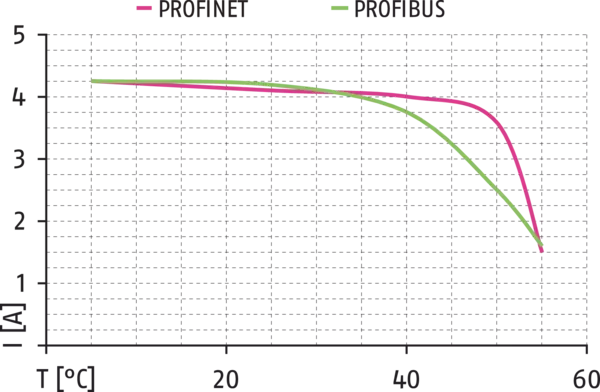

Snížení

Diagram škrcení ukazuje maximální povolený proud motoru v závislosti na okolní teplotě.

- X-axis:

- Okolní teplota

- Y-axis:

- Proud motoru

Obecné pokyny k řadě

Uchopovací síla

je aritmetický součet individuální síly vyvinuté na každé chapadlo ve vzdálenosti P (viz obrázek)

Délka prstu

se měří od referenčního povrchu jako vzdálenost P ve směru hlavní osy.

Opakovatelná přesnost

je definována jako rozložení koncových poloh během 100 po sobě jdoucích zdvihů.

Hmotnost obrobku

se vypočítá jako silové uchopování se součinitelem statického třetí 0,1 a bezpečnostním faktorem 2 proti vyklouznutí obrobku při zrychlení v důsledku gravitace g. V případě uchopení s tvarovým stykem jsou přípustné významně vyšší hmotnosti obrobku

Zavírací a otvírací časy

Minimální doby zavírání a otevírání zahrnují pouze doby pohybu základních čelistí nebo prstů při maximální rychlosti, max. zrychlení bez elektrických omezení (maximální proud) a za dodržení maximální přípustné hmotnosti na každý prst.

Jmenovité proudy

mohou být spouštěny trvale. V případě hodnot proudu pohybujících se v rozmezí od jmenovitého proudu až do maximálního proudu je nutné se řídit odpovídající dokumentací.

Elektrická brzda

Zabudovaná elektrická přídržná brzda se používá k uchycení a držení polohy čelistí chapadla v případě výpadku napájení. Nemůže pokrývat veškeré bezpečnostní funkce nebo funkce udržení uchopovací síly.

Princip fungování

Princip hřebene a pastorku

Materiál těla

Hliníková slitina, potažená

Materiál základních čelistí

42CrMo4+QT

Spouštění

servoelektrický, pomocí bezkartáčového stejnosměrného servomotoru

Záruka

24 měsíců

Rozsah dodávky

Chapadlo včetně bezpečnostních informací a sady příslušenství se středicími pouzdry pro montáž chapadla a prstu. Návody a software pro konkrétní produkt si můžete stáhnout na stránkách schunk.com/downloads-manuals a schunk.com/downloads-software.