EOA-UR3510-EGL90

ID 1392477

可替代的升级版产品:

- 单指行程: 42.5 mm

- 最小抓取力: 50 N

- 最大抓取力: 600 N

- 能源供应: 24 V DC

- 最高环境温度: 55 °C

技术细节

| 机器人兼容性 | UR 3/5/10/16 |

|---|---|

| 单指行程 [mm] | 42.5 |

| 最小抓取力 [N] | 50.0 |

| 最大抓取力 [N] | 600.0 |

| 建议工件重量 [kg] | 3.0 |

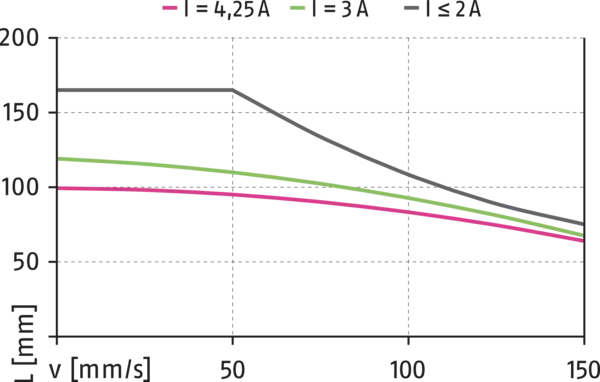

| 最大允许手指长度 [mm] | 165.0 |

| 每个手指的最大允许重量 [kg] | 0.5 |

| 重复精度 [mm] | 0.05 |

| 闭合时间 [s] | 0.7 |

| 打开时间 [s] | 0.7 |

| 最大速度 [mm/s] | 150.0 |

| 最大加速度 [mm/s²] | 2500.0 |

| 重量 [kg] | 2.13 |

| 最低环境温度 [°C] | 5.0 |

| 最高环境温度 [°C] | 55.0 |

| IP 防护等级 | 46 |

| 洁净室等级 ISO 14644-1:2015 | 4 |

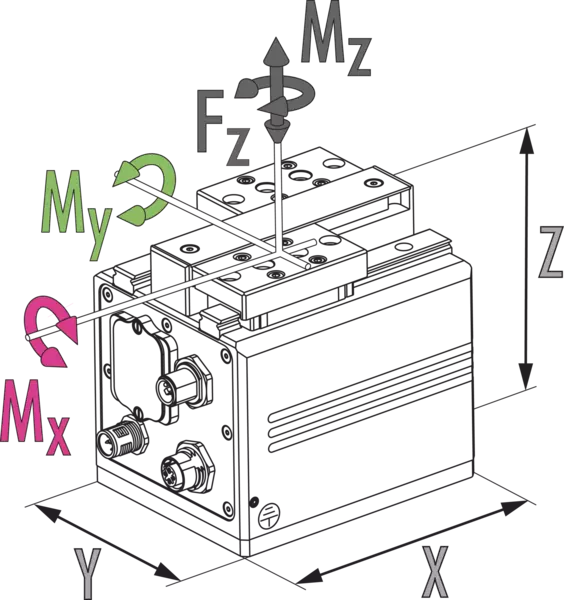

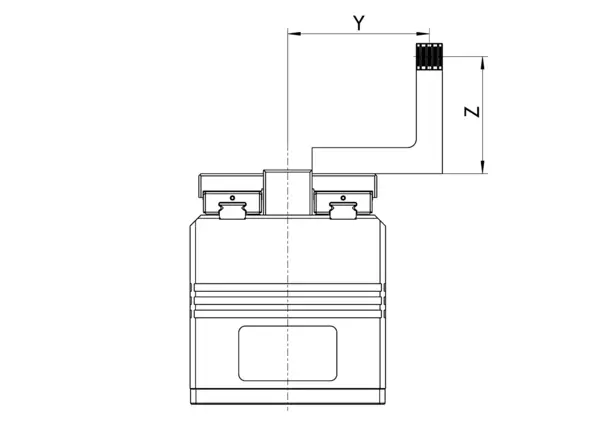

| 长度 X [mm] | 112.0 |

| 宽度 Y [mm] | 100.4 |

| 高度 Z [mm] | 121.0 |

| 控制器电子元件 | 配套 |

| 额定电压 | 24.0 |

| 通信接口 | PROFINET |

| 参数化接口 | USB |

| 最大工作电流 [A] | 2.5 |

| 最大逻辑电流 [A] | 0.5 |

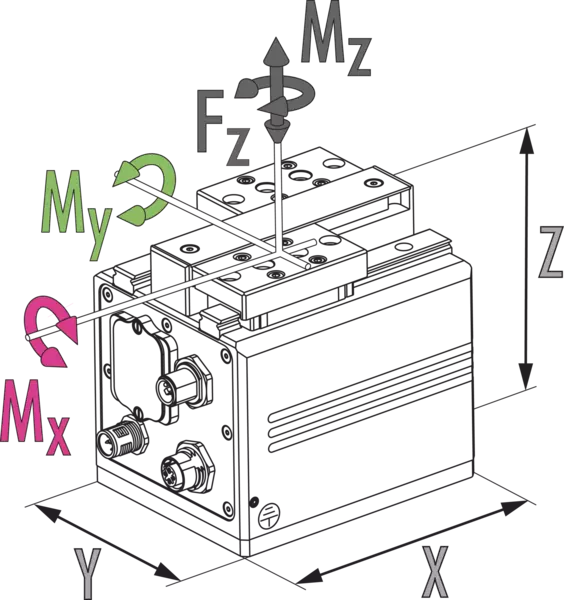

| 力矩 Mx max. [Nm] | 20.0 |

| 力矩 My max. [Nm] | 20.0 |

| 力矩 Mz max. [Nm] | 20.0 |

| 最大轴向力 Fz max。 [N] | 400.0 |

Dimensions and maximum loads

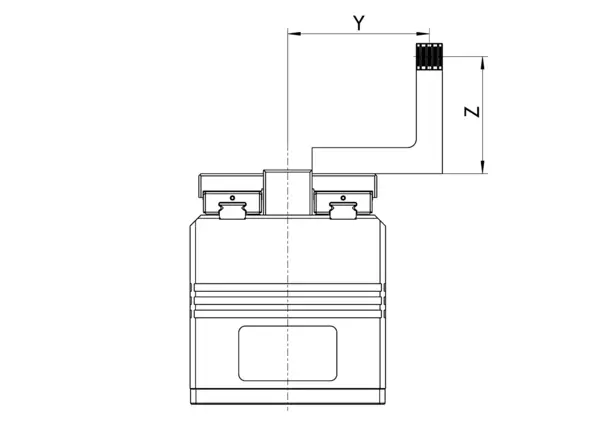

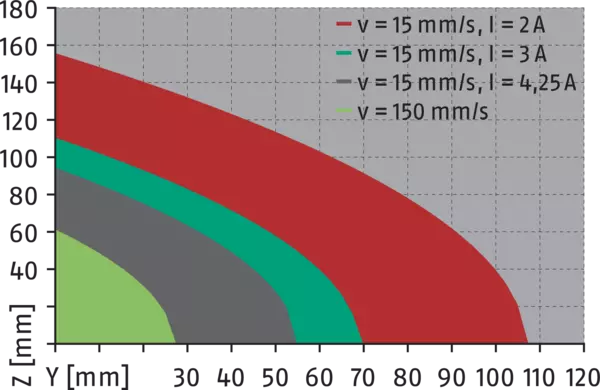

Maximum permitted finger projection

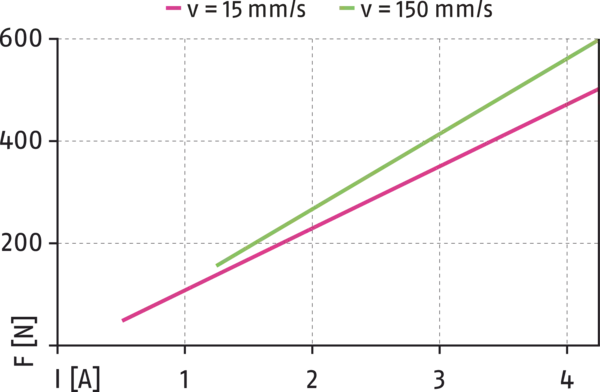

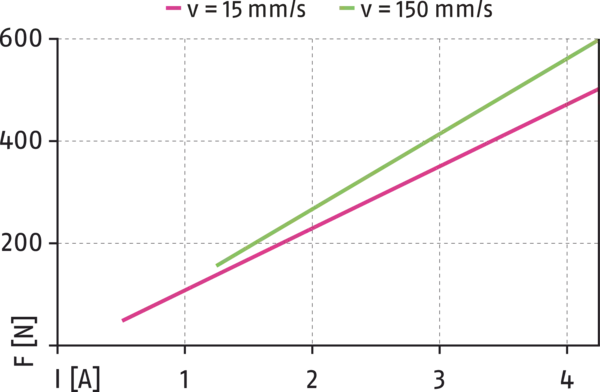

抓取力

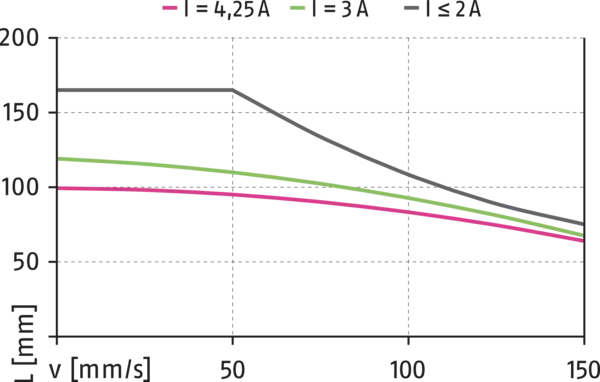

手指长度

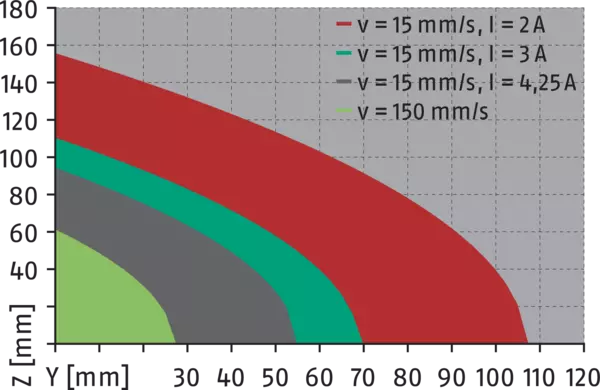

最大允许手指投影

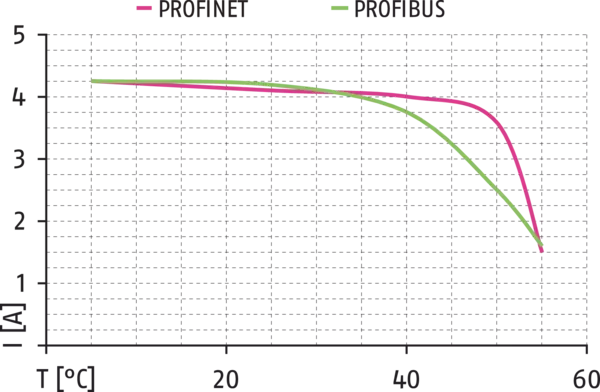

降低额定值

Dimensions and maximum loads

The indicated moments and forces are statical values, apply for each base jaw and may appear simultaneously. Loads may additionally occur to the moment produced by the gripping force itself.

Maximum permitted finger projection

抓取力

- X 轴:

- 电机电流

- Y 轴:

- 抓取力

手指长度

- X 轴:

- 卡爪速度

- Y 轴:

- 手指长度

最大允许手指投影

- grey

- 不允许的范围

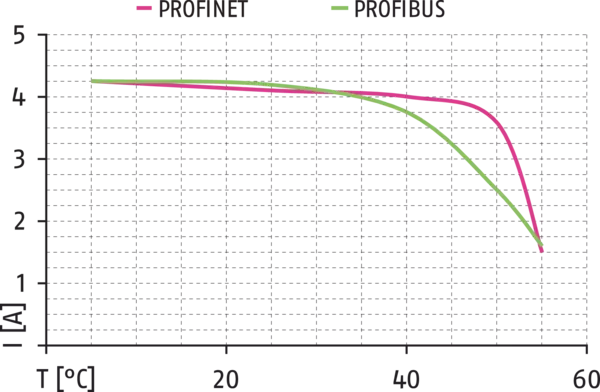

降低额定值

节流图显示出,依照环境温度变化的电机电流最大允许设置。

- X 轴:

- 环境温度

- Y 轴:

- Motor current

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

Minimum closing and opening times are merely the movement times of the base jaws or fingers at max. speed, max. acceleration, without current limitation (maximum current), and observance of the maximum permissible mass per finger.

Nominal currents

can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Electrical brake

The built-in, electric holding break is used for fixing and holding the position of the gripper jaws in the event of a power failure. It cannot cover all of the security or gripping force maintenance functions.

Operating principle

Rack and pinion principle

Housing material

Aluminum alloy, coated

Base jaw material

42CrMo4+QT

Actuation

servo-electric, via brushless DC servomotor

Warranty

24 months

Scope of delivery

Gripper including safety information and accessory kit with centering sleeves for gripper and finger mounting. Product-specific instructions and software can be downloaded at schunk.com/downloads-manuals and schunk.com/downloads-software.