KGG 100-80

IDnr. 303066

- Slag per klem: 40 mm

- Sluitkracht: 175 N

- Openingskracht: 220 N

- Max. omgevingstemperatuur: 90 °C

Technische gegevens

| Slag per klem [mm] | 40.0 |

|---|---|

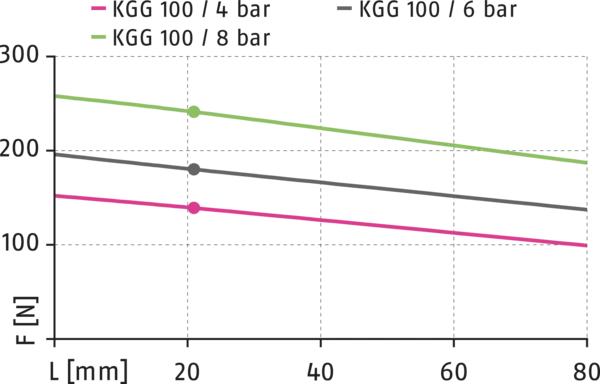

| Sluitkracht [N] | 175.0 |

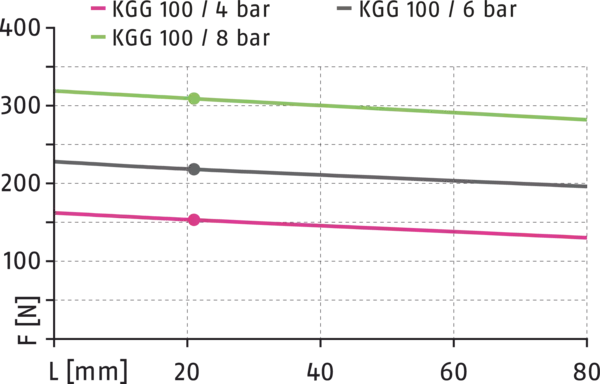

| Openingskracht [N] | 220.0 |

| Sluitkracht (bij vingerlengte van 0 mm) [N] | 189.0 |

| Openingskracht (bij vingerlengte van 0 mm) [N] | 229.0 |

| Gewicht [kg] | 0.5 |

| Aanbevolen gewicht werkstuk [kg] | 0.9 |

| Cilindervolume per dubbele slag [cm³] | 45.0 |

| Min. werkdruk [bar] | 2.5 |

| Max. werkdruk [bar] | 8.0 |

| Nominale werkdruk [bar] | 6.0 |

| Sluitingstijd [s] | 0.19 |

| Openingstijd [s] | 0.15 |

| Max. toegelaten vingerlengte [mm] | 80.0 |

| Max. toegestaan gewicht per vinger [kg] | 0.3 |

| IP-beschermklasse | 20 |

| Min. omgevingstemperatuur [°C] | 5.0 |

| Max. omgevingstemperatuur [°C] | 90.0 |

| Rondloopnauwkeurigheid [mm] | 0.02 |

| Cleanroomklasse ISO 14644-1 | 7 |

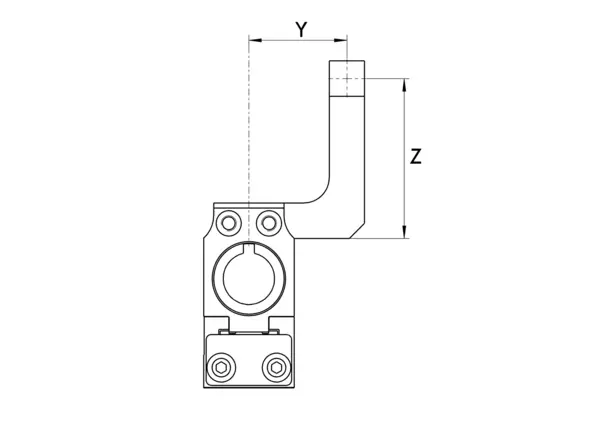

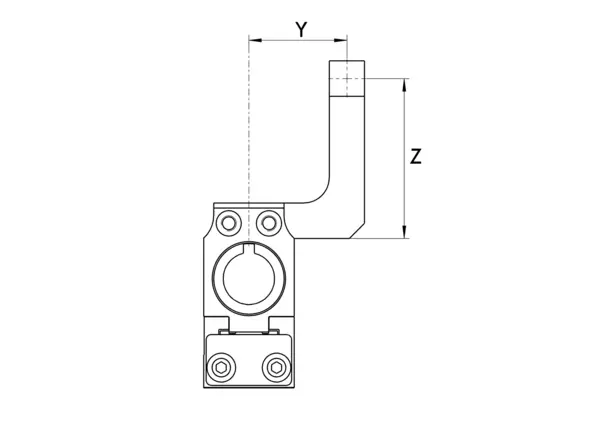

| Lengte X [mm] | 157.0 |

| Breedte Y [mm] | 31.0 |

| Hoogte Z [mm] | 49.3 |

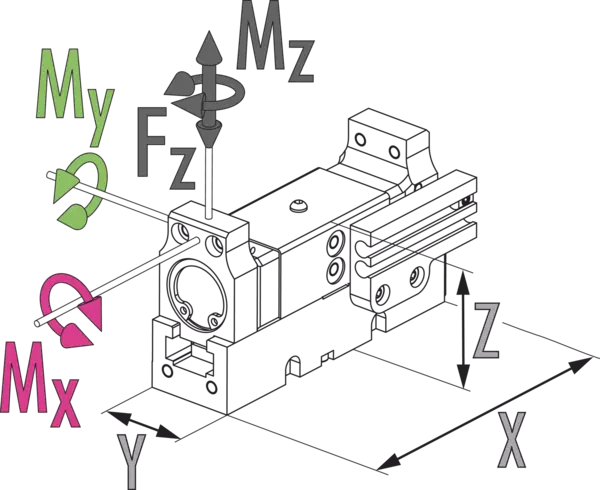

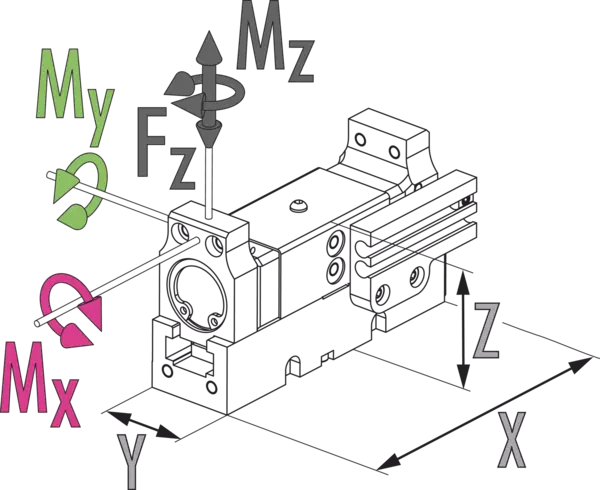

| Moment Mx max. [Nm] | 4.4 |

| Moment My max. [Nm] | 7.4 |

| Moment Mz max. [Nm] | 9.5 |

| max. axiale kracht Fz max. [N] | 480.0 |

Afmetingen en maximaal toegelaten belasting

Maximaal toegelaten vingeraanzet

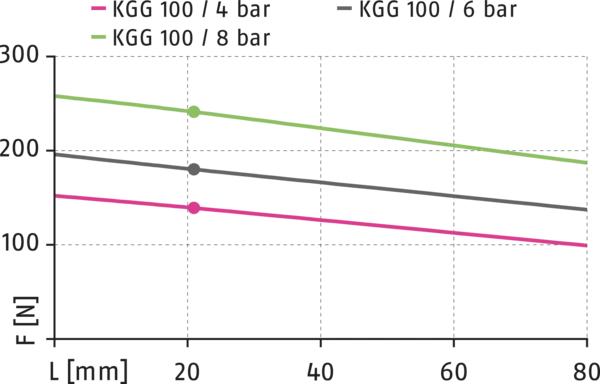

Grijpkracht, grijpen van buitendiameter

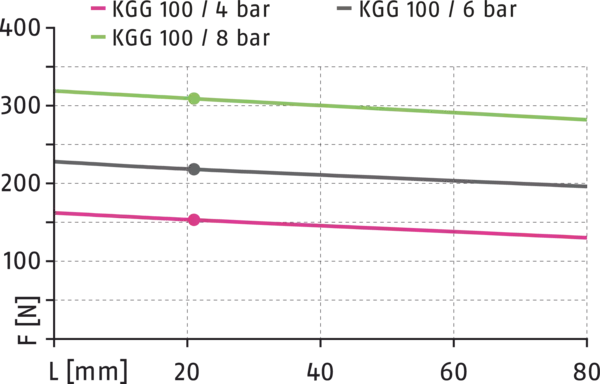

Grijpkracht, grijpen van binnendiameter

Maximaal toegelaten vingeraanzet

Afmetingen en maximaal toegelaten belasting

De opgegeven waarden voor moment en kracht zijn statische waarden, gelden voor elke basisklem en kunnen tegelijkertijd voorkomen. Naast het moment dat door de grijpkracht zelf wordt gegeneerd, kunnen er nog extra lasten optreden.

Maximaal toegelaten vingeraanzet

Grijpkracht, grijpen van buitendiameter

- X-as:

- Punt P - Vingerlengte

- Y-as:

- Grijpkracht

Grijpkracht, grijpen van binnendiameter

- X-as:

- Punt P - Vingerlengte

- Y-as:

- Grijpkracht

Maximaal toegelaten vingeraanzet

Lmax is gelijk aan de maximaal toegestane vingerlengte. Zie de tabel met technische gegevens

- green

- Toegelaten bereik

- grey

- Niet-toelaatbaar bereik

Algemene opmerkingen over de reeks

Grijpkracht

is de rekenkundige som van de individuele kracht die vanaf afstand P op elke klem wordt uitgeoefend (zie afbeelding).

Vingerlengte

wordt gemeten uit het referentieoppervlak als de afstand P in de richting van de hoofdas. De maximaal toegestane vingerlengte geldt totdat de nominale werkdruk wordt bereikt. Bij een hogere druk moet de vingerlengte evenredig worden verkort tot de nominale werkdruk.

Rondloopnauwkeurigheid

is gedefinieerd als verdeling van de eindpositie voor 100 opeenvolgende slagen.

Gewicht werkstuk

wordt berekend voor grijpen met een perspassing met een statische wrijvingscoëfficiënt van 0,1 en veiligheidsfactor 2 tegen wegglijden van het werkstuk bij versnelling als gevolg van zwaartekracht g. Voor vormsluiting of invanging ligt het toegestane gewicht van de werkstukken aanzienlijk hoger.

Sluitings- en openingstijden

zijn bewegingstijden van alleen de basisklemmen, zonder toepassingsspecifieke grijpervingers. Dit is exclusief de tijden voor klepomschakeling, het vullen van de slangen of de PLC-responstijden. Deze moeten bij het berekenen van de cyclustijden in acht worden genomen.

Werkingsprincipe

Direct aangedreven basisklemmen, gesynchroniseerd door tandheugelsysteem

Materiaal behuizing

Aluminiumlegering, geanodiseerd

Materiaal basisklem

Aluminiumlegering, geanodiseerd

Aandrijving

pneumatisch, met gefilterde perslucht conform ISO 8573-1:2010 [7:4:4].

Garantie

24 maanden

Kenmerken levensduur

op verzoek

Levering

Grijper in de bestelde variant, accessoireset (centreerhulzen, O-ringen voor directe aansluiting/gedetailleerde inhoud zie bedieningshandleiding) en veiligheidsinformatie. Productspecifieke instructies kunnen gedownload worden op schunk.com/downloads-handleidingen.

Behoud van grijpkracht

mogelijk met klep voor drukbehoud SDV-P