As a contract manufacturer, Torneria Novoletto produces components as its Italian location in Lainate near Milan for end users in the chemical, pharmaceutical, and medical industries. The employees are also the owners – three brothers who continue to run the company founded by their grandfather in 1984. They primarily process materials such as aluminum, steel titanium, and cobalt-chrome into complex small parts with a workpiece weight of up to around two kilograms. The company initially produced the components mechanically on manual milling machines and introduced the first numerically controlled machine center in 2003 – today, ten machines are in operation.

“The special challenge in our case with component manufacturing is the high precision and high process reliability,“ emphasizes Massimo Novoletto, one of the three company owners of Torneria Novoletto.“ The machining operations we carry out typically involve medium-sized batches, but each part takes a considerable amount of time to complete — up to two or three hours. With only three employees in the workshop, it was not possible to fully utilize the machines. Until now, the machining centers have only been running for relatively short periods — a maximum of ten hours per day — and remained idle at night. This inefficiency was further exacerbated by the fact that Torneria Novoletto struggled to find qualified and experienced machine operators. Like many workshops and companies, they were affected by the shortage of skilled workers — a key factor that prevented the full productivity potential of the machines and systems from being realized.

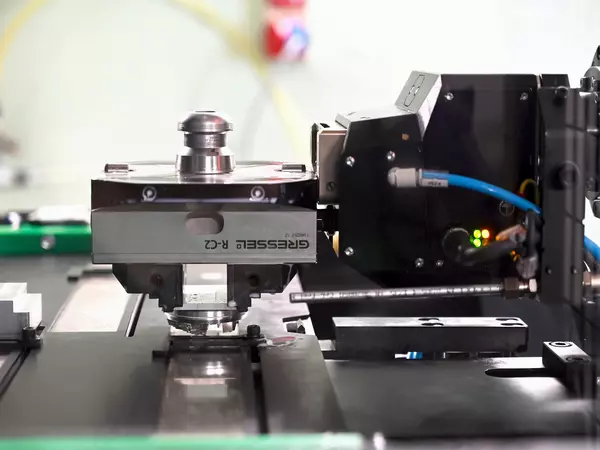

“Thanks to our long-standing supplier Uemme from Coccaglio, we were already using modern quality equipment, quick-change pallet systems, clamping pallets with vises, and SCHUNK toolholders,” Edoardo Novoletto continues. “By continuously optimizing the operating equipment and process reliability, we were able to improve machine set-up times and part quality – but it still wasn’t enough.” One solution to further optimize production and handle peak loads was automation. For Torneria Novoletto, a key goal was to increase machine utilization – for example, by enabling around-the-clock, unmanned operation. “In addition to the need to work unmanned 24 hours a day, we were determined to optimize production by transitioning from a manual to an automated process that can flexibly respond to peak workloads,“ explains Eduardo Novoletto. Torneria Novoletto has been familiar with SCHUNK’s workpiece and tool clamping devices for years. Based on the strong relationship and close cooperation with the automation specialist, the two partners discussed potential solutions tailored to the company’s specific production requirements. After evaluating all feasible options, the decision was made in favor of the R-C2 system – a hybrid solutions combining pallet automation and direct workpiece loading. With the R-C2 clamping block, which both grips and clamps the workpiece, users can continuously handle workpieces of varying sizes in a single process – without the need for manual adjustments, which minimizes set-up times. This allows for example, to machine complex parts and series productions with high flexibility, precision, and efficiency.

A special feature of the R-C2 is the six-sided station, which enables automatic reclamping of the workpiece for OP20 and allows complete machining from all six sides. This functionality sets the R-C2 system apart and offers added value.

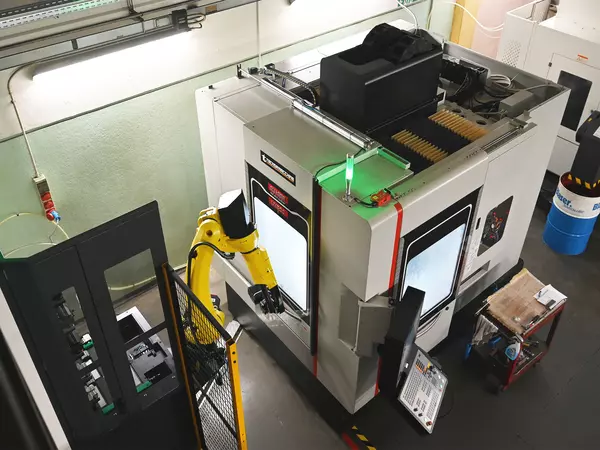

“We decided to purchase a new Quaser UX500 five-axis machining center from TECNOR Macchine and integrated the R-C2 system. This automated solution was the best fit for our requirements,“ Massimo Novoletto states. With the R-C2 a single device takes over both the workpiece handling from the magazine and the positioning and clamping of the workpiece on the machine. “In short, it is a clamping module mounted on the robot’s wrist. It first picks up the self-centering vise, which is then used to retrieve the raw part from a magazine. The clamping module now positions the self-centering vise including the clamped workpiece directly onto the quick-change pallet system of the machine tool. After machining, the robot removes the vise with the finished workpiece using the clamping module and places it into the finished parts magazine,“ describes Edoardo Novoletto the processes. System specialists from Labormak in Piacenza supported Torneria Novoletto in their workshop in Lainate with the implementation of the custom-developed automaton cell. This compete solution, with its versatility, can be adapted to the specific requirements of any production context. It also ensures plant safety, for example through the use of modern safety systems such as the FANUC DCS – an integrated software ensuring the safety of operators, robots, and tools – and protective devices like the floor-mounted laser scanner. These systems ensure operator safety and enable use of the cell without protective barriers.

For Alessandro Novoletto the technological unique selling point of the R-C2 system is convincing: „The system connects gripping and clamping of workpieces. It combines workpiece automation with pallet automation. This system automatically positions and clamps components without the need to procure separate clamping devices for each workpiece variant. Another advantage is its versatility: simply changing the jaws of the vise allows switching, for example, from a round to a prismatic workpiece. The long stroke of the vise ensures high flexibility. By using different vises, various products can be handled. Furthermore, autonomous production during nights and weekends is possible. „With this solution, we combine production optimization and unmanned manufacturing around the clock,“ confirms Massimo Novoletto.

For Torneria Novoletto, the solution we came up with is optimal because it excellently meets the production requirements regarding precision, parts variance, complexity of parts, and lot sizes. The company can now react flexibly to customer enquiries, reliably handle series orders, and increase production volume without additional personnel. Another important aspect for Torneria Novoletto is the simple operation and handling of the R-C2 system. Even less experienced employees can quickly learn how to control and program the system. The small company in northern Italy was able to switch to the new automation concept quickly and smoothly – it took only about eight months from the initial idea to the implementation of the system. Edoardo Novoletto is also convinced by the cooperative partnership with SCHUNK: “SCHUNK is the right partner for us to increase our productivity with the goal of maintaining our competitiveness. With the R-C2, we are now well positioned for the future.”