SWG 40

ID 305108

- Ángulo de apertura: 15 °

- Par de cierre: 1.2 Nm

- Temperatura ambiente máx.: 90 °C

Información técnica

| Closing force (with finger lengths of 0 mm) [N] | 153.0 |

|---|---|

| Opening angle per jaw [°] | 15.0 |

| Closed angle per jaw up to [°] | 7.0 |

| Closing moment [Nm] | 1.2 |

| Closing moment generated by spring [Nm] | 0.36 |

| Weight [kg] | 0.106 |

| Recommended workpiece weight [kg] | 0.24 |

| Cylinder volume per double stroke [cm³] | 1.6 |

| Min. operating pressure [bar] | 4.0 |

| Max. operating pressure [bar] | 6.5 |

| Nominal operating pressure [bar] | 6.0 |

| Closing time [s] | 0.025 |

| Opening time [s] | 0.03 |

| Max. permissible finger length [mm] | 35.0 |

| Max. permissible weight per finger [kg] | 0.05 |

| IP protection class | 30 |

| Min. ambient temperature [°C] | 5.0 |

| Max. ambient temperature [°C] | 90.0 |

| Repeat accuracy [mm] | 0.05 |

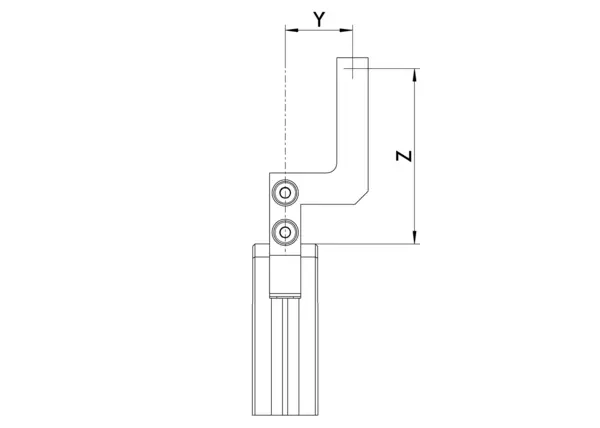

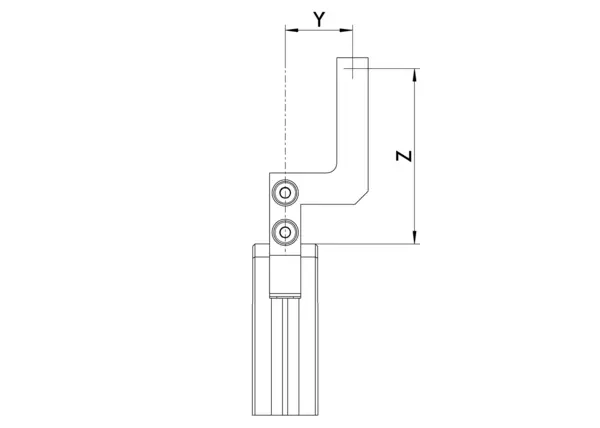

| Length X [mm] | 40.0 |

| Width Y [mm] | 20.0 |

| Height Z [mm] | 52.0 |

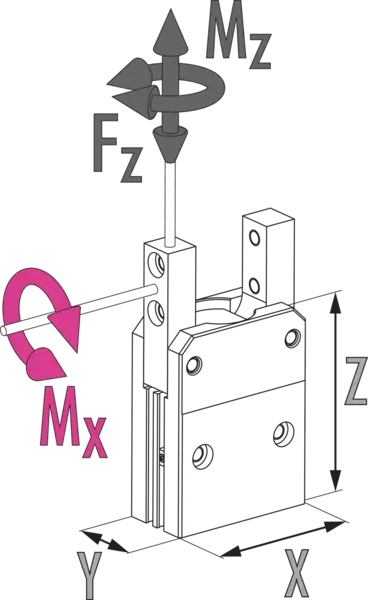

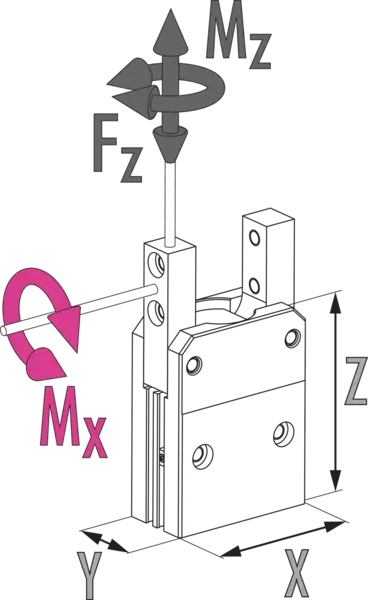

| Moment Mx max. [Nm] | 0.35 |

| Moment Mz max. [Nm] | 0.35 |

| Max. axial force Fz max. [N] | 30.0 |

Dimensions and maximum loads

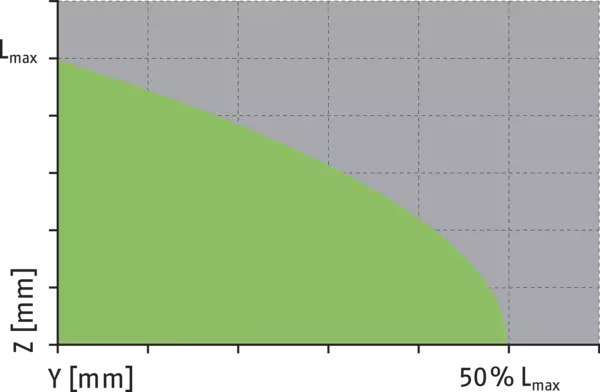

Maximum permitted finger projection

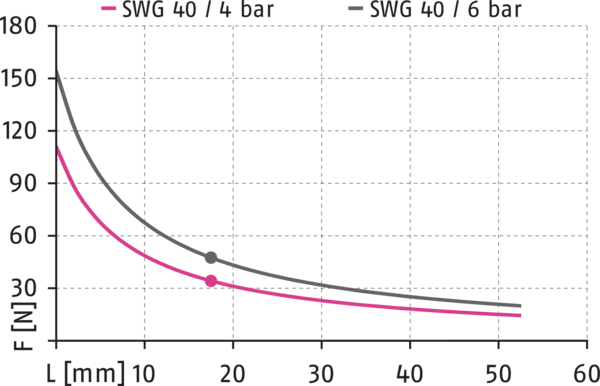

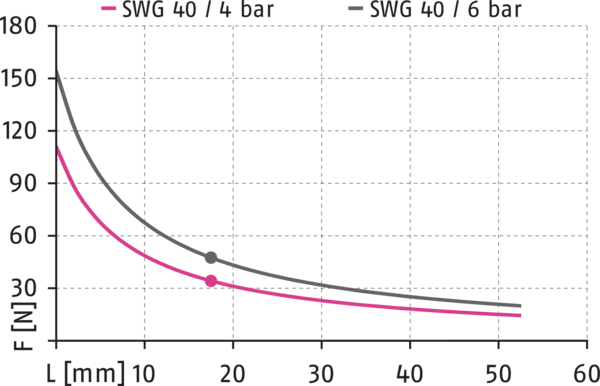

Gripping force O.D. gripping

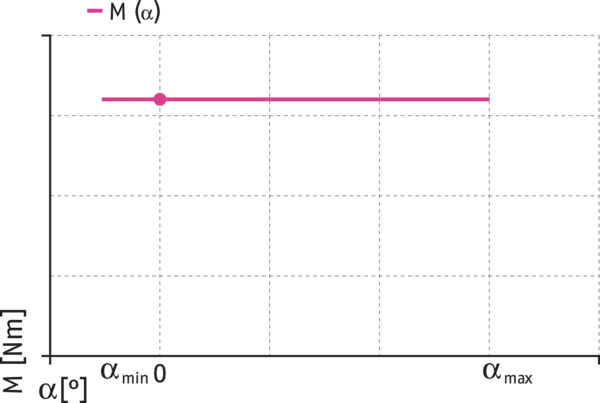

Closing moment curve

Maximum permitted finger projection

Dimensions and maximum loads

The indicated torques and forces are static values, apply for each base jaw, and may occur simultaneously.

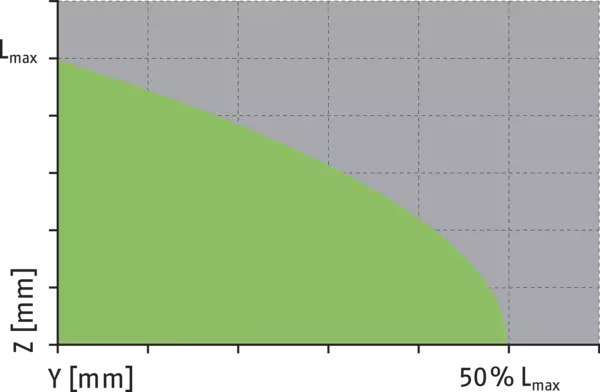

Maximum permitted finger projection

Gripping force O.D. gripping

- Eje X:

- Point P - Finger length

- Eje Y:

- Gripping force

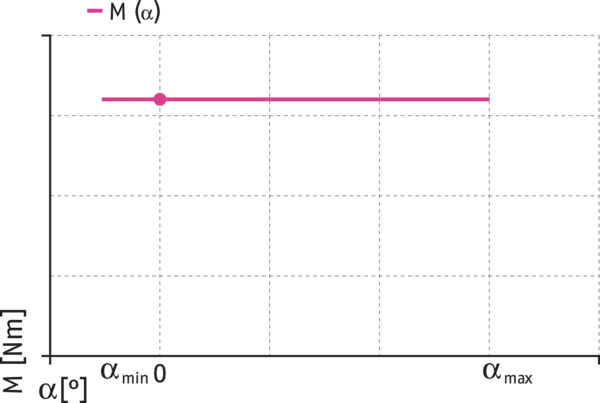

Closing moment curve

- Eje X:

- Opening angle

- Eje Y:

- Closing moment

Maximum permitted finger projection

Lmax is equivalent to the maximum permitted finger length, see the technical data table.

- green

- Permitted range

- grey

- Inadmissible range

General notes about the series

Closing moment

is the arithmetic sum of the individual moment applied to each jaw.

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Closing and opening times

are movement times of the base jaws only, without application-specific gripper fingers. Valve switching times, hose fill times, or PLC reaction times are not included, and are to be considered when cycle times are calculated.

Operating principle

double-acting, guided kinematics

Housing material

Aluminum alloy, anodized

Base jaw material

Aluminum alloy, anodized

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Warranty

24 months

Service life characteristics

on request

Scope of delivery

Gripper in the ordered variant, accessory kit (centering sleeves/detailed contents see operating manual) and safety information. Product-specific instructions can be downloaded at schunk.com/downloads-manuals.

Gripping force maintenance

always integrated by using springs, and also possible via pressure maintenance valve SDV-P