GSM-P 50-AS-E-090

ID 304651

- 片側ストローク: 8 mm

- 回転角度: 90 °

- 閉力: 135 N

- 停止位置調節範囲: 90 °

- トルク: 2.9 Nm

技術的詳細

| 片側ストローク [mm] | 8.0 |

|---|---|

| 閉力 [N] | 135.0 |

| 最小スプリング力 [N] | 30.0 |

| トルク [Nm] | 2.9 |

| 回転角度 [°] | 90 |

| 停止位置調節範囲 [°] | 90.0 |

| 振動減衰 (旋回) | エラストマー |

| 推奨ワーク重量 [kg] | 0.52 |

| エア消費 (把持) [cm³] | 10.84 |

| エア消費 (旋回) [cm³] | 51.0 |

| 重量 [kg] | 1.53 |

| 呼び作動圧力 [bar] | 6.0 |

| 最大作動圧 [bar] | 6.5 |

| 最小作動圧 (把持) [bar] | 4.0 |

| 最小作動圧 (旋回) [bar] | 3.0 |

| 閉時間 [s] | 0.01 |

| 開時間 [s] | 0.02 |

| 中程度の寸法のアタッチメント負荷での旋回時間** [s] | 0.14 |

| 最大許容フィンガー長 [mm] | 50.0 |

| 最大許容重量/フィンガー [kg] | 0.14 |

| セットアップの最大許容慣性 [kgmm²] | 176.0 |

| IP 保護等級 | 30 |

| 最低周囲温度 [°C] | 5.0 |

| 最高周囲温度 [°C] | 90.0 |

| 繰り返し精度 (把持) [mm] | 0.02 |

| 繰り返し精度 (旋回) [°] | 0.1 |

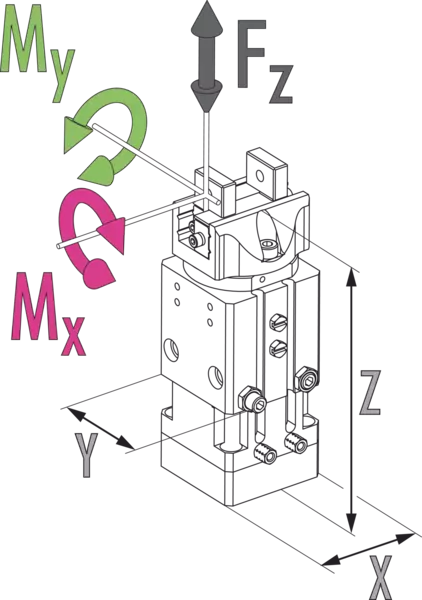

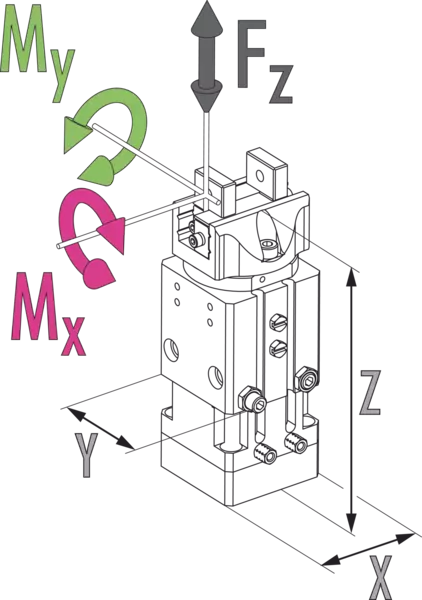

| 長さ X [mm] | 64.0 |

| 幅 Y [mm] | 73.5 |

| 高さ Z [mm] | 161.0 |

| モーメント Mx 最大 [Nm] | 3.0 |

| トルク My 最大 [Nm] | 4.0 |

| モーメント Mz最大 [Nm] | 5.0 |

| 最大軸方向力 Fz (最大) [N] | 200.0 |

寸法と最大荷重

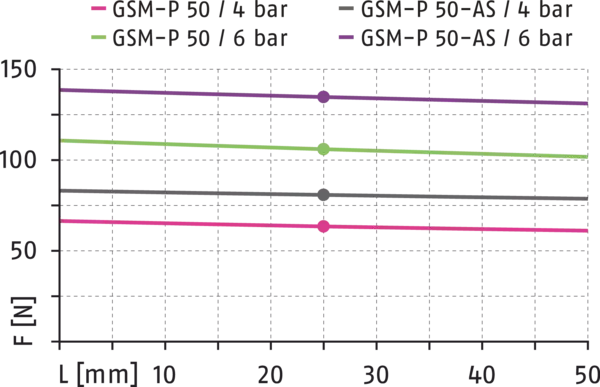

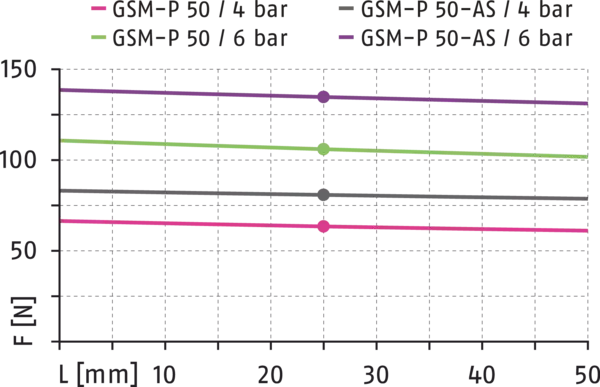

把持力、外径把持

寸法と最大荷重

示されたモーメントと荷重は固定値であり、各ベースジョーに作用し、同時発生することがあります。また、荷重は、把持力自体によって生成されたモーメントと別に発生することがあります。

把持力、外径把持

- X 軸:

- ポイント P - フィンガー長

- Y 軸:

- 把持力

General notes about the series

Gripping force

is the arithmetic sum of the individual force applied to each jaw at distance P (see illustration).

Finger length

is measured from the reference surface as the distance P in direction to the main axis.

Workpiece weight

is calculated for force-fit gripping with a coefficient of static friction of 0.1 and a safety factor of 2 against workpiece slippage at acceleration due to gravity g. For form-fit or capture gripping, there are significantly higher permissible workpiece weights.

Repeat accuracy

is defined as a distribution of the end Position for 100 consecutive strokes.

Closing, opening and swiveling times

Closing and opening times are movement times of the base jaws only, without application-specific gripper fingers. Swivel times are the pure movement timesof the rotating part. Valve switching times, hose fill times, or PLC reaction times are not included, and are to be considered when cycle times are calculated.

Middle attached load

intended to represent a typical load. It is defined as the half of the max. possible mass moment of inertia that can be swiveled without restriction, bouncing or hitting, with a centric load and a vertical rotating axis.

Operating principle

Combined rotor and piston drive

Housing material

Aluminum alloy, anodized

Base jaw material

Steel

Actuation

pneumatic, with filtered compressed air as per ISO 8573-1:2010 [7:4:4].

Warranty

24 months

Service life characteristics

on request

Scope of delivery

Centering sleeves, O-rings for direct connection, screws for lateral fastening, steel balls for adjustment of the swiveling angle, assembly and operation manual with declaration of incorporation

Gripping force maintenance

possible by using the version with mechanical gripping force maintenance or pressure maintenance valve SDV-P