PR 2-110-51-PB-I

ID 359570

- ギア比: 51:1

- トルク: 25.5 Nm

- 定格電流: 12 A

- 電源: 24 V

技術的詳細

| 定格トルク [Nm] | 25.5 |

|---|---|

| 最大トルク [Nm] | 62.5 |

| 停止トルク [Nm] | 29.6 |

| 公称速度 [1/min] | 22.5 |

| 最大回転速度 [1/min] | 42.0 |

| 最大許容質量慣性モーメント [kgm²] | 1.5 |

| 繰り返し精度 [°] | 0.03 |

| トランスミッション | 51:1 |

| トルク My 最大 [Nm] | 120.0 |

| 力 Fx max. [N] | 1000.0 |

| 力 Fz 最大 [N] | 895.0 |

| ブレーキ | あり |

| 重量 [kg] | 6.4 |

| 最低周囲温度 [°C] | 5.0 |

| 最高周囲温度 [°C] | 50.0 |

| IP 保護等級 | 40 |

| 長さ X [mm] | 140.0 |

| 幅 Y [mm] | 110.0 |

| 高さ Z [mm] | 220.5 |

| 公称電圧 [V] | 24.0 |

| 定格電流 [A] | 12.0 |

| 最大電流 [A] | 22.0 |

| 制御機器 | 内蔵 |

| 電源 [V] | 24.0 |

| エンコーダーシステム | エンコーダー (増分) |

| PROFIBUS インターフェース [Mbit/s] | 12.0 |

| USB インターフェース | ホスト/デバイス |

| デジタル入力端子数 | 2.0 |

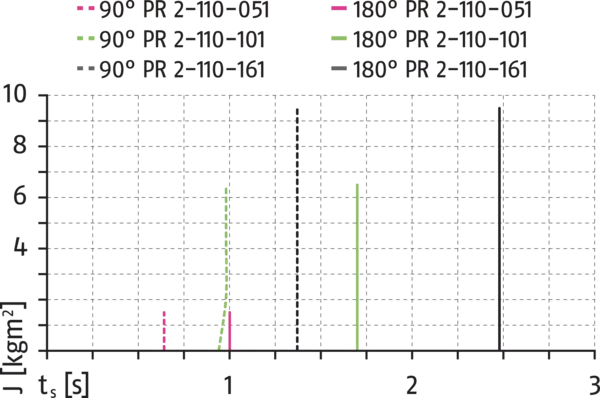

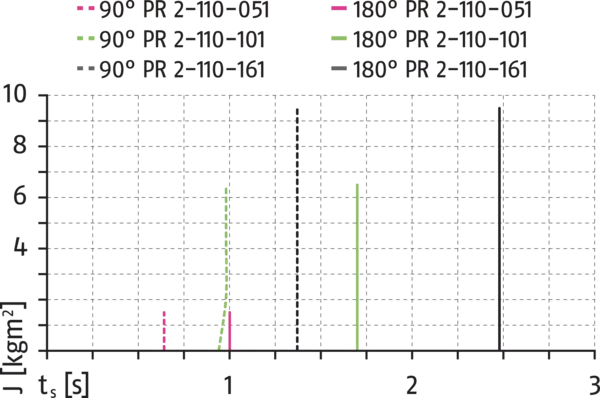

周囲温度、速度、加速度および慣性に応じて、適切なアイドル時間が決定されます。

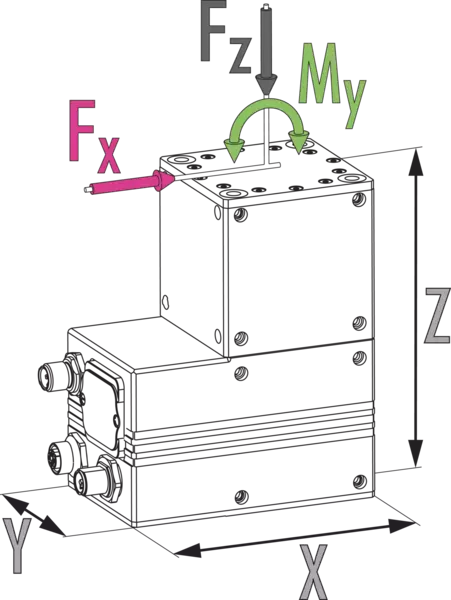

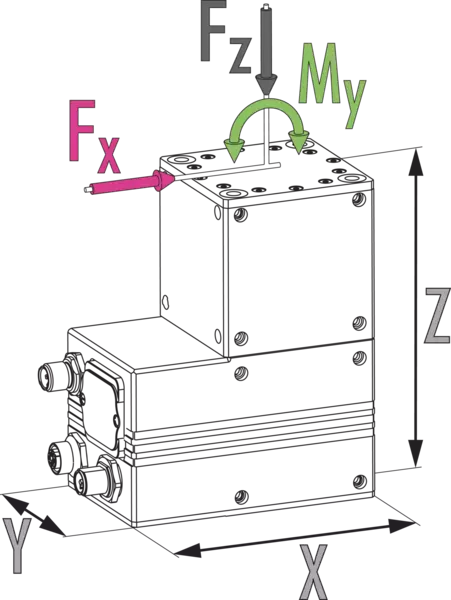

Dimensions and maximum loads

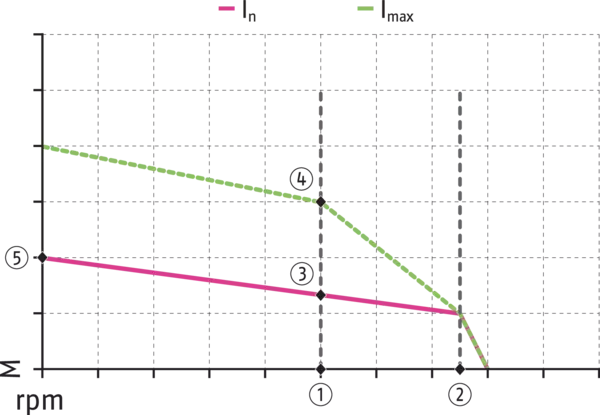

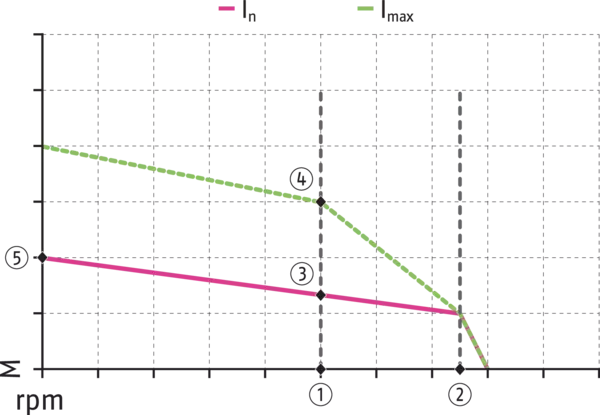

トルク速度の仕様

Swivel time diagram

Dimensions and maximum loads

Moments and forces may occur simultaneously.

トルク速度の仕様

- X 軸:

- 回転の速度

- Y 軸:

- トルク

- 01

- 公称速度

- 02

- 最大回転速度

- 03

- 定格トルク

- 04

- 最大トルク

- 05

- 停止トルク

Swivel time diagram

- X 軸:

- Swiveling time

- Y 軸:

- Inertia

- X軸上部:

- Cycles per hour

General notes about the series

Swiveling times

are purely the times of the module to rotate from rest position to rest position. Relay switching times or PLC reaction times are not included in the above times and must be taken into consideration when determining cycle times. Load-dependent rest periods may have to be included in the cycle time.

Repeat accuracy

Is defined as the spread of the target position after 100 consecutive positioning cycles.

Nominal currents

can be permanently actuated. With regard to all the currents which are ranging above the nominal current up to the maximum current, the notes of the individual product documentation has to be respected.

Electrical brake

The installed, electric holding brake serves to fix and hold the position in case of power failure up to the rated torque. It cannot cover any complete safety functions.

Peak torque

The peak torques serve as short-term drive reserves when accelerating and delaying.

Housing material

Aluminum alloy, coated

Actuation

servo-electric, via brushless DC servomotor

Operating principle

Harmonic drive® gear driven directly via brushless DC servomotor

Scope of delivery

DVD with SCHUNK software and commissioning assistant, includes assembly and operating manual, declaration of incorporation, functional module for control via Siemens S7.

Warranty

24 months