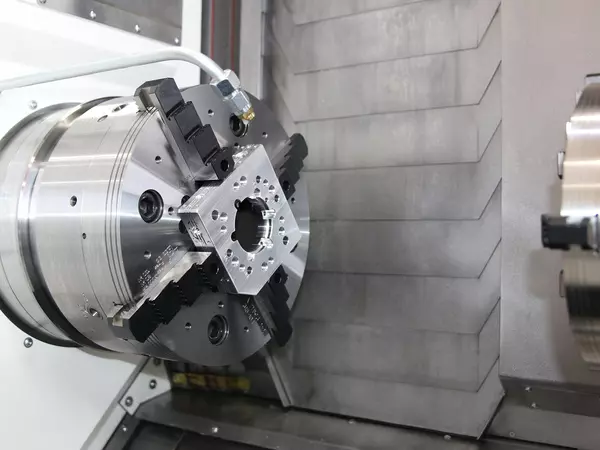

Contract manufacturers and machining companies know how important process-stable and versatile clamping devices are. Especially for batch size 1 and high part variability in custom production, short setup times and flexibility are essential. Since modern turn/mill centers perform turning and milling simultaneously, a reliable and flexible clamping device is indispensable for precise workpiece machining – particularly when geometrically undefined or irregular parts need to be machined in a second clamping operation. SCHUNK now provides an innovative clamping concept for these demanding requirements with the new ROTA THW3 2+2 power lathe chuck. This 4-jaw lathe chuck features two independent jaw pairs with subsequent centrally compensating workpiece clamping, enabling safe and reliable clamping of freeform parts, castings, or geometrically undefined workpieces. Thanks to the patented sealing, companies can confidently use this 2+2 compensation lathe chuck in harsh environments with dirt and fine chips. In addition, users benefit from consistently high clamping forces and significantly extended maintenance intervals, resulting in increased productivity without compromising quality

Following the manual lathe chucks, SCHUNK now introduces a 2+2 jaw compensation lathe chuck for power lathe chucks, which is particularly indispensable for automated applications. The new power lathe chuck provides centrally compensating workpiece clamping for all workpiece geometries, making it an ideal solution for complex parts on lathes. This flexibility allows parts to be completed on lathes that previously required an additional milling operation. The integrated jaw quick-change system enables users to adapt the chuck quickly and easily to new clamping tasks, resulting in a significant increase in productivity. Thanks to the sealing, the maintenance effort is reduced, lowering lubricant consumption and minimizing used grease – making SCHUNK a key contributor to resource-efficient manufacturing processes

SCHUNK will offer the flexible lathe chuck from mid-2026 in sizes 230, 265, and 315 millimeters in diameter.